Can Ti-6Al-4V sheets be heat-treated?

2025-03-10 16:31:05

View:389

2025-03-10 16:31:05

View:389Heat treatment is a critical process in the manufacturing and processing of titanium alloys, particularly for Ti-6Al-4V sheets, which are widely used across various industries for their exceptional properties. This blog post explores the heat treatment possibilities for Ti-6Al-4V titanium sheets, including processes, benefits, challenges, and applications.

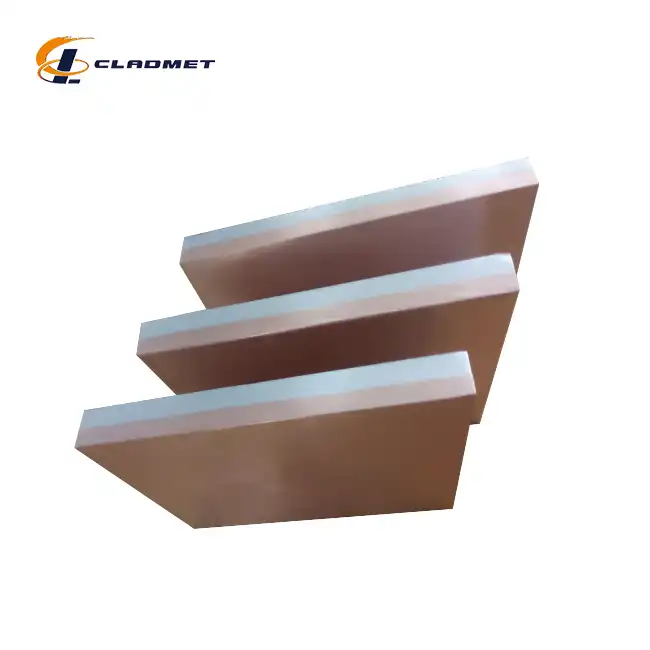

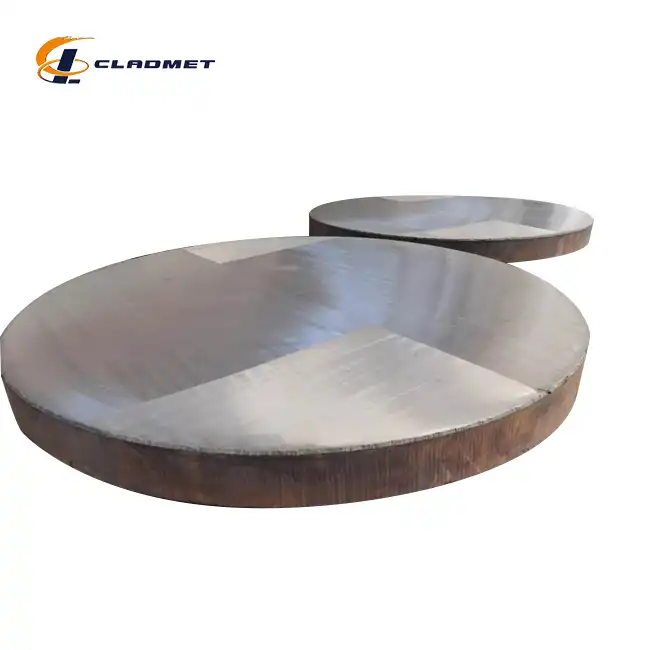

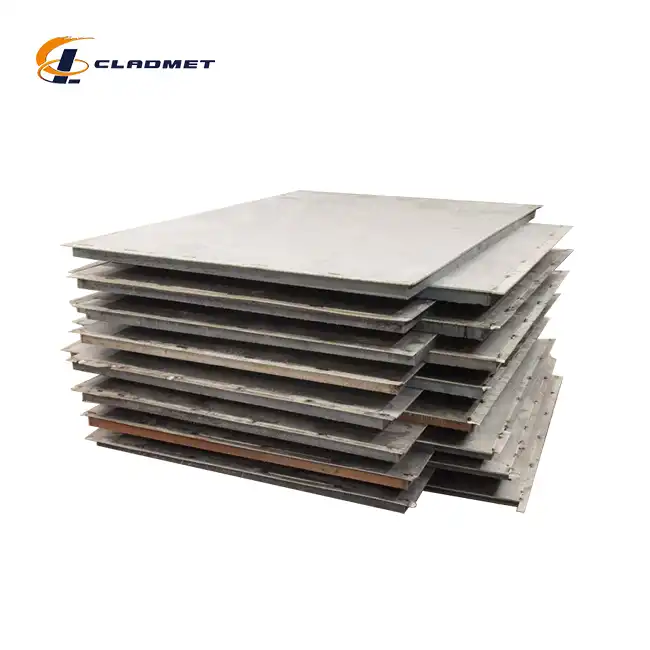

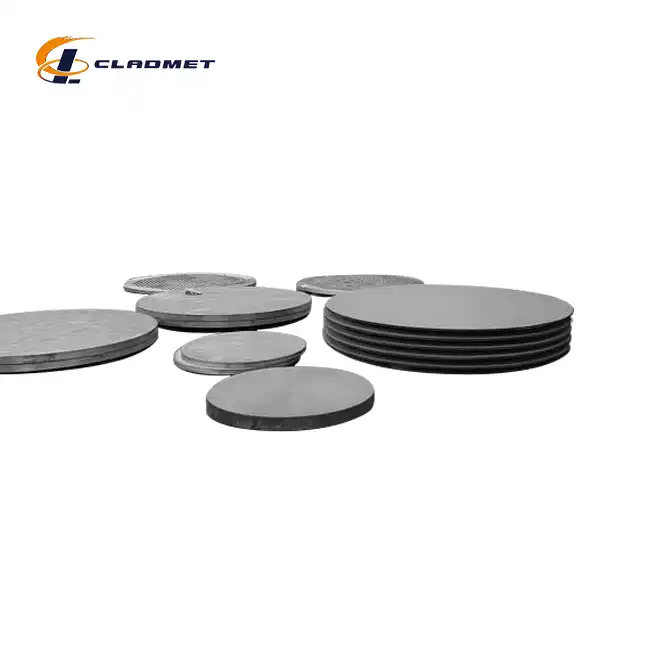

6Al 4V titanium sheets can indeed be heat-treated, and this process is often essential to optimize their mechanical properties. Ti-6Al-4V is an alpha-beta titanium alloy that responds excellently to various heat treatment methods including annealing, solution treating, and aging. The heat treatment of 6al 4v titanium sheet can significantly enhance its strength, ductility, fatigue resistance, and fracture toughness. These treatments typically involve controlled heating to specific temperatures followed by precise cooling regimens, which alter the microstructure of the material. The specific heat treatment method selected depends on the desired mechanical properties and the intended application of the 6al 4v titanium sheet. At Baoji JL Clad Metals Materials Co., Ltd., we offer various heat treatment options for our titanium products to meet the diverse requirements of our global clientele.

Heat Treatment Processes for Ti-6Al-4V Sheets

Annealing Techniques for Improved Formability

Annealing is one of the most commonly applied heat treatments for 6al 4v titanium sheet products. This process involves heating the material to a specific temperature range (typically 700-850°C) and holding it there for a predetermined time before cooling at a controlled rate. The primary purpose of annealing 6al 4v titanium sheet is to reduce internal stresses, increase ductility, and improve formability while maintaining adequate strength. Different annealing techniques can be employed depending on the specific requirements, including mill annealing, duplex annealing, and recrystallization annealing. Mill annealing is the most common and economical process, which involves heating to approximately 750°C followed by air cooling. This treatment is particularly beneficial for 6al 4v titanium sheet products with thicknesses ranging from 0.5 mm to 100 mm, as offered by Baoji JL Clad Metals Materials Co., Ltd. Our annealing processes comply with international standards including ASTM B265 and AMS 4911, ensuring consistent quality across our product range. For aerospace and medical applications where dimensional stability is crucial, our precisely controlled annealing treatments provide the optimal balance of mechanical properties.

Solution Treatment and Aging (STA)

Solution Treatment and Aging (STA) is a sophisticated heat treatment process that significantly enhances the mechanical properties of 6al 4v titanium sheet. The process involves two main steps: first, heating the 6al 4v titanium sheet to a temperature above the beta transus (typically 900-950°C) followed by rapid quenching, and second, aging at lower temperatures (usually 480-595°C) for several hours. This treatment creates a fine, uniform distribution of alpha and beta phases, resulting in exceptional strength and toughness combinations. STA-treated 6al 4v titanium sheet exhibits superior fatigue resistance and fracture toughness, making it ideal for critical aerospace components and medical implants. Baoji JL Clad Metals Materials Co., Ltd. offers STA-treated 6al 4v titanium sheet in various dimensions, with widths ranging from 100 mm to 2000 mm and customizable lengths to meet specific application requirements. Our advanced processing facilities allow for precise temperature control during heat treatment, ensuring consistent properties throughout the material. The production process, whether hot rolling or cold rolling, is carefully selected based on the customer's specifications and the intended application of the 6al 4v titanium sheet, with delivery cycles typically within 4-6 weeks depending on order specifics.

Stress Relief Heat Treatment

Stress relief heat treatment is essential for 6al 4v titanium sheet products that have undergone forming, machining, or welding operations, as these processes introduce internal stresses that could lead to dimensional instability or premature failure. The stress relief process for 6al 4v titanium sheet typically involves heating to moderate temperatures (usually 480-650°C) for a specified time (typically 1-4 hours), followed by slow cooling. This treatment effectively reduces residual stresses without significantly altering the microstructure or mechanical properties of the material. For precision components manufactured from 6al 4v titanium sheet, stress relief heat treatment is crucial to ensure dimensional stability during service, particularly in applications exposed to elevated temperatures or cyclical loading. Baoji JL Clad Metals Materials Co., Ltd. provides comprehensive stress relief heat treatment services for our 6al 4v titanium sheet products, catering to various industry requirements including aerospace, automotive, and marine applications. Our rigorous quality control procedures ensure that all heat-treated materials meet the stringent requirements of international standards such as ASTM B265 and AMS 4911. We offer standard export packaging for our heat-treated 6al 4v titanium sheet products, with multiple transportation options including sea, air, and rail freight to ensure timely delivery to our global customers.

Microstructural Changes During Heat Treatment

Alpha-Beta Phase Transformations

The microstructural evolution during heat treatment of 6al 4v titanium sheet is primarily governed by the transformation between alpha and beta phases. Ti-6Al-4V contains approximately 6% aluminum, which stabilizes the alpha phase, and 4% vanadium, which stabilizes the beta phase. During heat treatment, the proportion and morphology of these phases change significantly, directly influencing the mechanical properties of the 6al 4v titanium sheet. When heated above the beta transus temperature (approximately 980°C), the microstructure transforms completely to beta phase. Upon cooling, the beta phase decomposes into various morphologies of alpha phase, depending on the cooling rate. Slow cooling results in coarse alpha plates, while rapid cooling produces fine needle-like alpha structures (martensite). At Baoji JL Clad Metals Materials Co., Ltd., we meticulously control the heating and cooling parameters to achieve the desired microstructure in our 6al 4v titanium sheet products. Our manufacturing capabilities allow for the production of sheets with thicknesses ranging from 0.5 mm to 100 mm, each with carefully controlled microstructures tailored to specific application requirements. The transformation kinetics are particularly important for thicker 6al 4v titanium sheet products, where thermal gradients can lead to non-uniform microstructures if not properly managed during heat treatment.

Grain Size Control and Its Effects

Grain size is a critical microstructural feature that significantly influences the mechanical properties of 6al 4v titanium sheet. Heat treatment parameters, including temperature, time, and cooling rate, directly affect the grain size and subsequently the strength, ductility, and fatigue resistance of the material. Fine-grained microstructures generally exhibit higher strength and improved fatigue performance, while coarser grains may provide better creep resistance at elevated temperatures. For 6al 4v titanium sheet applications requiring an optimal balance of properties, precise grain size control is essential. Baoji JL Clad Metals Materials Co., Ltd. employs advanced metallurgical techniques to control grain growth during heat treatment, ensuring consistent and desirable mechanical properties across our entire range of 6al 4v titanium sheet products. Our manufacturing processes, including hot rolling and cold rolling, are specifically designed to maintain appropriate grain structures throughout production. For aerospace applications where fatigue resistance is paramount, we can provide 6al 4v titanium sheet with fine, equiaxed grain structures. Our quality control processes include microstructural examination to verify grain size and morphology in accordance with international standards. With widths ranging from 100 mm to 2000 mm and customizable lengths, our 6al 4v titanium sheet products are available in various grain size configurations to meet diverse industry requirements.

Precipitation Phenomena and Strengthening Mechanisms

The heat treatment of 6al 4v titanium sheet triggers various precipitation phenomena that contribute significantly to the strengthening of the material. During aging treatments, fine precipitates form within the microstructure, impeding dislocation movement and enhancing strength. In Ti-6Al-4V, several types of precipitates can form depending on the heat treatment parameters, including Ti3Al (alpha-2) in the alpha phase and various metastable phases in the beta regions. These precipitates play a crucial role in determining the final mechanical properties of the 6al 4v titanium sheet. Baoji JL Clad Metals Materials Co., Ltd. leverages deep metallurgical expertise to optimize precipitation phenomena in our heat treatment processes, delivering 6al 4v titanium sheet products with superior strength-to-weight ratios. Our manufacturing facilities are equipped with precision temperature control systems that ensure optimal precipitation conditions during heat treatment. For medical applications requiring high strength and excellent biocompatibility, we carefully control the precipitation process to achieve the desired combination of properties in our 6al 4v titanium sheet products. Our rigorous testing procedures, compliant with ASTM B265 and AMS 4911 standards, confirm that the precipitate distribution and resulting mechanical properties meet or exceed customer specifications. The strengthening mechanisms are particularly important for applications in automotive and marine sectors, where 6al 4v titanium sheet must withstand challenging environmental conditions while maintaining structural integrity.

Industrial Applications and Performance

Aerospace Industry Requirements and Solutions

The aerospace industry demands the highest standards of performance and reliability from materials, making heat-treated 6al 4v titanium sheet an ideal choice for numerous critical applications. In aircraft structures, heat-treated 6al 4v titanium sheet offers an exceptional combination of high strength, low density, and excellent corrosion resistance. Different heat treatment protocols are employed to optimize specific properties required for various aerospace components. For instance, solution-treated and aged 6al 4v titanium sheet is preferred for high-strength structural components, while annealed variants are used where formability and damage tolerance are prioritized. Baoji JL Clad Metals Materials Co., Ltd. supplies premium-quality heat-treated 6al 4v titanium sheet to aerospace manufacturers worldwide, with our products meeting the rigorous standards set by the industry, including AMS 4911. Our manufacturing capabilities allow for the production of 6al 4v titanium sheet in thicknesses ranging from 0.5 mm to 100 mm and widths from 100 mm to 2000 mm, accommodating the diverse requirements of aerospace applications. Our heat treatment processes are specifically tailored to enhance fatigue resistance and fracture toughness, critical properties for components subjected to cyclic loading and potential impact damage. The strict quality control measures implemented at our facilities ensure that each batch of 6al 4v titanium sheet meets or exceeds the stringent requirements of aerospace manufacturers, with delivery cycles typically within 4-6 weeks to accommodate production schedules.

Medical Applications and Biocompatibility Considerations

Heat-treated 6al 4v titanium sheet has become indispensable in the medical industry, particularly for implants and surgical instruments, due to its exceptional biocompatibility, corrosion resistance, and mechanical properties. The heat treatment process significantly influences the biocompatibility of 6al 4v titanium sheet by affecting surface properties, oxide layer formation, and potential ion release. Annealed 6al 4v titanium sheet is commonly used for medical implants that require good formability and fatigue resistance, while solution-treated and aged variants provide higher strength for load-bearing applications such as orthopedic implants. Baoji JL Clad Metals Materials Co., Ltd. specializes in producing medical-grade 6al 4v titanium sheet with precisely controlled heat treatment parameters to optimize biocompatibility and mechanical performance. Our manufacturing processes strictly adhere to international standards, ensuring that our 6al 4v titanium sheet products meet the rigorous requirements for medical applications. We offer customized dimensions and surface finishes to accommodate specific medical device designs, with our advanced processing capabilities enabling the production of sheets as thin as 0.5 mm for delicate applications. Our comprehensive quality control system, certified to ISO 9001:2000 standards, includes rigorous testing for mechanical properties, chemical composition, and microstructural characteristics to ensure consistent performance in medical environments. The exceptional corrosion resistance of our heat-treated 6al 4v titanium sheet makes it ideal for long-term implants that must withstand the aggressive environment of the human body.

Automotive and Industrial Performance Metrics

The automotive and industrial sectors increasingly adopt heat-treated 6al 4v titanium sheet for applications requiring an optimal balance of strength, weight reduction, and durability. The specific heat treatment protocols are selected based on the performance metrics critical for each application, including fatigue strength, impact resistance, and high-temperature stability. In automotive applications, heat-treated 6al 4v titanium sheet is utilized for components such as valve springs, connecting rods, and exhaust systems, where weight reduction and high-temperature performance are essential. For industrial applications, heat-treated 6al 4v titanium sheet offers exceptional corrosion resistance in aggressive chemical environments, making it ideal for chemical processing equipment. Baoji JL Clad Metals Materials Co., Ltd. provides customized heat treatment solutions for 6al 4v titanium sheet products destined for automotive and industrial applications, with capabilities to produce sheets in widths ranging from 100 mm to 2000 mm and thicknesses from 0.5 mm to 100 mm. Our manufacturing processes, including hot rolling and cold rolling, are carefully selected based on the specific requirements of each application. We employ advanced testing methodologies to verify mechanical properties such as tensile strength, yield strength, elongation, and fatigue resistance, ensuring that our 6al 4v titanium sheet products meet the demanding performance metrics of automotive and industrial applications. With standard export packaging and multiple transportation options including sea, air, and rail freight, we ensure timely delivery of our products to customers worldwide, typically within a 4-6 week delivery cycle depending on order specifications.

Conclusion

Heat treatment is undoubtedly a viable and essential process for Ti-6Al-4V sheets, offering manufacturers the ability to tailor mechanical properties to specific application requirements. From aerospace to medical to automotive applications, properly heat-treated 6al 4v titanium sheet delivers exceptional performance, combining strength, corrosion resistance, and biocompatibility into one versatile material.

At Baoji JL Clad Metals Materials Co., Ltd., we pride ourselves on our expertise in titanium processing and heat treatment. Our independent explosive composite technology, self-rolling capabilities, and international qualifications enable us to deliver premium-quality 6al 4v titanium sheet products tailored to your exact specifications. With our innovative approach to titanium processing and unwavering commitment to quality, we continue to push the boundaries of what's possible with this remarkable material. Are you ready to enhance your products with optimally heat-treated Ti-6Al-4V sheets? Contact our expert team today at sales@cladmet.com to discuss your specific requirements and discover how our advanced titanium solutions can elevate your projects to new heights.

References

1. Williams, J.C. & Lutjering, G. (2007). Titanium (Engineering Materials and Processes). Springer-Verlag Berlin Heidelberg.

2. Donachie, M.J. (2000). Titanium: A Technical Guide (2nd Edition). ASM International.

3. Boyer, R., Welsch, G., & Collings, E.W. (1994). Materials Properties Handbook: Titanium Alloys. ASM International.

4. Peters, M., Kumpfert, J., Ward, C.H., & Leyens, C. (2003). Titanium Alloys for Aerospace Applications. Advanced Engineering Materials, 5(6), 419-427.

5. Rack, H.J. & Qazi, J.I. (2006). Titanium alloys for biomedical applications. Materials Science and Engineering: C, 26(8), 1269-1277.

6. Semiatin, S.L., Seetharaman, V., & Weiss, I. (1997). The thermomechanical processing of alpha/beta titanium alloys. JOM, 49(6), 33-39.

_1737007724117.webp)

_1736996330512.webp)

_1740558024479.webp)

_1737612858536.webp)