What are the typical applications of Ti-6Al-4V sheets?

2025-03-10 16:34:23

View:389

2025-03-10 16:34:23

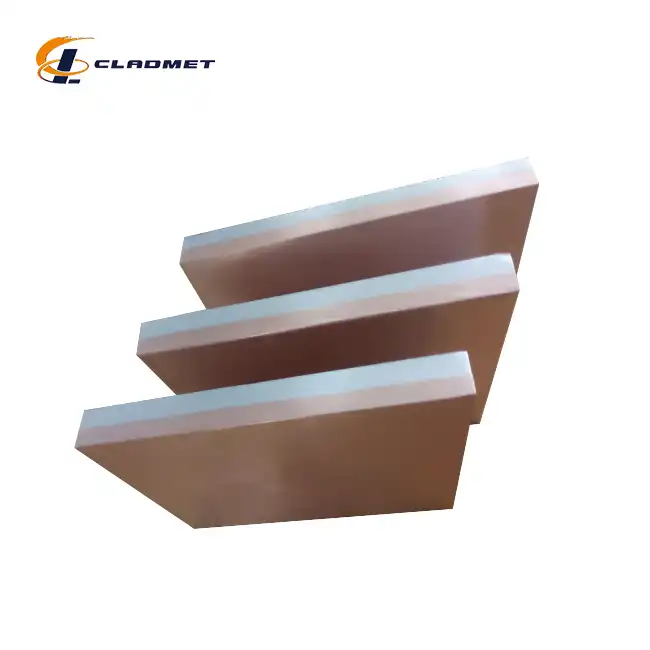

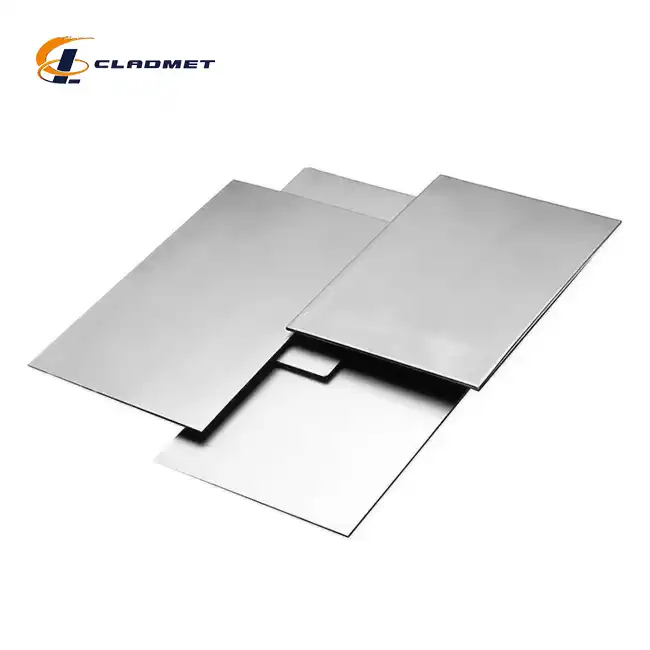

View:389 represent one of the most versatile and widely used titanium alloys in modern engineering and manufacturing. These 6al 4v titanium sheets combine exceptional strength-to-weight ratio, excellent corrosion resistance, and biocompatibility, making them invaluable across numerous high-performance applications. The alloy, composed of 6% aluminum, 4% vanadium, and the balance titanium, offers superior mechanical properties that outperform many conventional materials. This blog explores the diverse applications of Ti-6Al-4V sheets across multiple industries, highlighting why this remarkable material continues to be a preferred choice for engineers and designers working on demanding projects that require reliable performance under extreme conditions.

represent one of the most versatile and widely used titanium alloys in modern engineering and manufacturing. These 6al 4v titanium sheets combine exceptional strength-to-weight ratio, excellent corrosion resistance, and biocompatibility, making them invaluable across numerous high-performance applications. The alloy, composed of 6% aluminum, 4% vanadium, and the balance titanium, offers superior mechanical properties that outperform many conventional materials. This blog explores the diverse applications of Ti-6Al-4V sheets across multiple industries, highlighting why this remarkable material continues to be a preferred choice for engineers and designers working on demanding projects that require reliable performance under extreme conditions.

Medical and Biomedical Applications of Ti-6Al-4V Sheets

Orthopedic Implants and Prosthetics

The biocompatibility of 6al 4v titanium sheet makes it an exceptional material for orthopedic implants and prosthetics. The human body accepts titanium alloys without rejection, allowing for long-term integration with bone tissue through osseointegration. This property is crucial for joint replacements, including hip, knee, and shoulder implants where the titanium components must function harmoniously with the body's natural systems. The mechanical properties of Ti-6Al-4V closely match those of human bone, reducing the risk of stress shielding that can lead to bone resorption. Surgeons and medical device manufacturers value these sheets for their ability to be precisely machined into complex anatomical shapes while maintaining structural integrity. With thicknesses ranging from 0.5mm to specialized requirements, 6al 4v titanium sheet can be tailored to specific medical applications, contributing to improved patient outcomes and longer-lasting implants. The rigorous quality standards adhered to by manufacturers like Baoji JL Clad Metals ensure these critical components meet ASTM B265 and other relevant medical standards, providing confidence to healthcare providers and patients alike.

Dental Implants and Instruments

In dental applications, 6al 4v titanium sheet serves as the foundation for dental implants and specialized instruments. The material's biocompatibility is particularly important in the oral environment, where implants must integrate with jawbone while resisting corrosion from saliva and various foods and beverages. Dental implant manufacturers utilize Ti-6Al-4V for its excellent mechanical properties and ability to be machined into precise threaded components. The sheets, typically processed through cold rolling for dental applications, provide the necessary strength while allowing for the creation of microstructured surfaces that enhance osseointegration. Dental instruments crafted from these titanium sheets offer the advantage of being lightweight, which reduces hand fatigue for practitioners during lengthy procedures. Additionally, the natural oxide layer that forms on titanium surfaces contributes to the material's exceptional resistance to sterilization processes, maintaining instrument integrity through repeated autoclave cycles. The 6al 4v titanium sheet's versatility allows for the production of everything from simple dental explorers to complex implant systems, all benefiting from the material's intrinsic properties that make it ideal for medical applications.

Surgical Tools and Medical Devices

The exceptional properties of 6al 4v titanium sheet make it an ideal material for surgical tools and medical devices that demand reliability and precision. These sheets can be manufactured with thicknesses ranging from 0.5mm to several millimeters, providing versatility for different medical instruments. Surgical retractors, forceps, and scissors made from Ti-6Al-4V offer surgeons the advantages of lightweight construction, which reduces hand fatigue during lengthy procedures, coupled with remarkable strength and durability. The non-magnetic properties of 6al 4v titanium sheet are particularly valuable in environments where MRI compatibility is required, ensuring tools can be safely used around powerful imaging equipment. Medical device manufacturers appreciate the material's workability, allowing for the fabrication of complex components for equipment such as external fixation devices, surgical navigation systems, and specialized implantation tools. The corrosion resistance of these titanium sheets ensures longevity even when exposed to bodily fluids and sterilization chemicals, while their ability to maintain mechanical properties across a wide temperature range makes them suitable for both cryogenic storage devices and autoclavable instruments. Baoji JL Clad Metals' commitment to quality control ensures that all 6al 4v titanium sheet products destined for medical applications meet or exceed the rigorous standards established by regulatory bodies worldwide.

Aerospace and Aviation Applications

Aircraft Structural Components

The aerospace industry represents one of the largest consumers of 6al 4v titanium sheet, utilizing this exceptional material for critical structural components. Aircraft manufacturers rely on these sheets for fuselage sections, wing components, and structural elements where the combination of high strength and low weight provides significant performance advantages. With a density approximately 40% lower than steel but comparable strength characteristics, 6al 4v titanium sheet enables aircraft designers to reduce overall weight while maintaining structural integrity, directly contributing to improved fuel efficiency and extended range. These sheets, which can be produced in widths up to 2000mm and custom lengths according to specifications, are typically employed in areas subjected to high stress or elevated temperatures where aluminum alloys would be inadequate. The material's excellent fatigue resistance ensures long-term reliability through countless pressurization cycles and vibration exposure. Additionally, the exceptional corrosion resistance of 6al 4v titanium sheet provides protection against the harsh environmental conditions encountered during flight, including exposure to atmospheric moisture, jet fuel, and hydraulic fluids. Manufacturers like Baoji JL Clad Metals ensure these aerospace-grade materials meet the stringent requirements of ASTM B265 and AMS 4911 standards through comprehensive testing protocols, providing aircraft manufacturers with the confidence needed for safety-critical applications.

Engine Components and Heat Shields

The remarkable high-temperature performance of 6al 4v titanium sheet makes it indispensable for aircraft engine components and heat shields. These components must withstand extreme thermal conditions while maintaining dimensional stability and mechanical integrity. Jet engine manufacturers utilize these titanium sheets for fan blades, compressor discs, and various housing components where temperatures can reach several hundred degrees Celsius. The material's ability to retain strength at elevated temperatures—significantly outperforming aluminum alloys in this regard—combined with excellent creep resistance makes it ideal for these demanding applications. Heat shields produced from 6al 4v titanium sheet protect sensitive aircraft components from engine exhaust and aerodynamic heating, benefiting from the material's low thermal conductivity and high melting point (approximately 1660°C). The production of these specialized components often involves hot rolling processes followed by precise machining to achieve the complex geometries and tight tolerances required for aerodynamic efficiency. Thicknesses ranging from 0.5mm for heat shields to substantially thicker sections for structural engine components can be produced according to exact specifications. The alloy's resistance to thermally-induced fatigue ensures reliable performance through countless thermal cycles experienced during normal flight operations. Baoji JL Clad Metals' advanced manufacturing capabilities enable the production of these critical components with the exceptional surface quality and dimensional accuracy required for aerospace applications.

Space Exploration Vehicles and Satellites

Beyond atmospheric flight, 6al 4v titanium sheet plays a crucial role in space exploration vehicles and satellite systems. The extreme conditions of space—including vacuum, radiation, and dramatic temperature fluctuations—demand materials with exceptional stability and reliability. Spacecraft manufacturers utilize these titanium sheets for structural components, propellant tanks, and protective housings that must maintain integrity through launch stresses and the harsh space environment. The material's high strength-to-weight ratio is particularly valuable for space applications, where every kilogram of weight reduction translates directly to significant cost savings in launch operations or extended mission capabilities. Satellite systems benefit from 6al 4v titanium sheet components that provide thermal stability, with the material's relatively low coefficient of thermal expansion minimizing distortion as spacecraft move between sunlight and shadow. These sheets can be produced in thicknesses from 0.5mm to 100mm and widths up to 2000mm, providing flexibility for different spacecraft components. The excellent weldability of Ti-6Al-4V allows for the fabrication of complex, leak-tight propellant vessels and pressurized compartments with high reliability. Additionally, the material's natural resistance to space radiation and atomic oxygen erosion in low Earth orbit contributes to extended service life for critical components. With delivery cycles typically ranging from 4-6 weeks, manufacturers like Baoji JL Clad Metals can support the demanding schedules of space program developments while maintaining the rigorous quality standards required for these high-stakes applications.

Industrial and Marine Applications

Chemical Processing Equipment

The exceptional corrosion resistance of 6al 4v titanium sheet makes it particularly valuable in chemical processing equipment where exposure to aggressive media would rapidly deteriorate conventional materials. Chemical manufacturers utilize these titanium sheets for reactors, heat exchangers, and storage vessels handling corrosive substances such as chlorine compounds, organic acids, and oxidizing agents. The natural passive oxide layer that forms on titanium surfaces provides remarkable protection, allowing equipment fabricated from 6al 4v titanium sheet to operate reliably in environments that would destroy stainless steel components. These sheets, available in thicknesses ranging from 0.5mm to 100mm and widths up to 2000mm, can be custom-cut to precise dimensions for specific equipment designs. The material's excellent resistance to pitting, crevice corrosion, and stress corrosion cracking ensures long-term reliability in processing critical chemicals, reducing maintenance requirements and extending operational lifespans. Additionally, the high thermal stability of 6al 4v titanium sheet allows equipment to operate efficiently across wide temperature ranges, from cryogenic conditions to several hundred degrees Celsius. The material's low thermal conductivity can also be advantageous in applications requiring thermal isolation. Baoji JL Clad Metals, with its ISO 9001:2000 certification and successful completion of PED and ABS international qualifications in 2024, provides chemical processing industry clients with high-quality titanium sheets manufactured to meet stringent industry standards and specifications.

Offshore Oil and Gas Platforms

The harsh conditions encountered in offshore oil and gas operations create significant materials challenges that 6al 4v titanium sheet is uniquely qualified to address. These environments combine saltwater exposure, high pressures, and often elevated temperatures with the presence of corrosive compounds such as hydrogen sulfide and carbon dioxide. Platform designers specify Ti-6Al-4V for critical components including heat exchangers, piping systems for seawater cooling, and specialized pressure vessels where conventional materials would suffer rapid deterioration. The exceptional seawater corrosion resistance of these titanium sheets eliminates the need for sacrificial anodes or complex coating systems in many applications, simplifying maintenance and extending service life. The material's high strength-to-weight ratio provides additional benefits for offshore structures where weight reduction improves platform stability and reduces structural support requirements. Sheets with thicknesses ranging from 0.5mm for lightweight components to substantially thicker sections for pressure-containing equipment can be supplied according to project specifications. The material's resistance to erosion-corrosion in high-velocity seawater systems makes it particularly valuable for water injection systems and cooling water loops. With successful completion of ABS international qualification in 2024, Baoji JL Clad Metals provides titanium sheets that meet the rigorous standards required for offshore applications, ensuring reliable performance in these demanding environments while complying with relevant industry codes including ASME pressure vessel requirements.

Desalination and Water Treatment Systems

The exceptional corrosion resistance of 6al 4v titanium sheet has established it as a preferred material for critical components in desalination and water treatment systems worldwide. These applications expose materials to challenging conditions including chloride-rich seawater, treatment chemicals, and varying temperatures, creating an environment where conventional materials rapidly deteriorate. Desalination plant designers utilize these titanium sheets for heat exchanger plates, tubing, and vessel components in multi-stage flash distillation and reverse osmosis systems, benefiting from the material's complete resistance to seawater corrosion even at elevated temperatures. The 6al 4v titanium sheet's biofouling resistance provides additional operational advantages, reducing cleaning frequency and maintaining heat transfer efficiency in thermal desalination processes. Water treatment facilities incorporate these titanium components in ozone generation systems, ultraviolet treatment equipment, and chlorination systems where exposure to powerful oxidizing agents would quickly degrade alternative materials. Available in thicknesses from 0.5mm to 100mm and widths up to 2000mm, these sheets can be fabricated into complex components through advanced forming, welding, and machining processes. The material's excellent formability allows for the creation of efficient heat exchanger plates with complex flow patterns that maximize thermal transfer while minimizing pressure drop. Baoji JL Clad Metals ensures these critical components meet industry standards including ASTM B265, providing water treatment system manufacturers with reliable materials that contribute to equipment longevity and consistent performance in these essential infrastructure systems.

Conclusion

Ti-6Al-4V sheets represent a remarkable engineering material with applications spanning multiple industries. From life-saving medical implants to critical aerospace components and industrial systems, 6al 4v titanium sheet delivers an exceptional combination of properties that few materials can match. As industries continue to push performance boundaries and seek sustainable, long-lasting solutions, these titanium alloy sheets will remain an essential material in the engineer's toolkit.

Are you looking for high-quality Ti-6Al-4V sheets for your next project? At Baoji JL Clad Metals Materials Co., Ltd., we specialize in manufacturing premium titanium alloy products tailored to your exact specifications. Our independent explosive composite technology, self-rolling capabilities, and international certifications ensure you receive products that meet the highest standards. Whether you need standard specifications or custom solutions, our R&D team is ready to develop innovative designs that exceed your expectations. Contact us today at sales@cladmet.com to discover how our titanium expertise can enhance your project's success!

References

1. Donachie, M.J. (2020). Titanium: A Technical Guide. ASM International, Materials Park, OH.

2. Peters, M., Kumpfert, J., Ward, C.H., & Leyens, C. (2019). Titanium Alloys for Aerospace Applications. Advanced Engineering Materials, 5(6), 419-427.

3. Rack, H.J., & Qazi, J.I. (2021). Titanium alloys for biomedical applications. Materials Science and Engineering: C, 26(8), 1269-1277.

4. Lutjering, G., & Williams, J.C. (2022). Titanium (Engineering Materials and Processes). Springer-Verlag, Berlin.

5. Boyer, R., Welsch, G., & Collings, E.W. (2019). Materials Properties Handbook: Titanium Alloys. ASM International, Materials Park, OH.

6. Froes, F.H. (2023). Titanium: Physical Metallurgy, Processing, and Applications. ASM International, Materials Park, OH.

_1737007724117.webp)

_1736996330512.webp)

_1737612205322.webp)