What are the dimensions and specifications of Pure Nickel Coated Plates?

2025-03-13 09:22:50

View:389

2025-03-13 09:22:50

View:389When exploring industrial-grade materials for demanding applications, understanding the dimensions and specifications of Pure Nickel Coated Plates is essential for making informed procurement decisions. These specialized metal products, manufactured by industry leaders like Baoji JL Clad Metals Materials Co., Ltd., offer exceptional corrosion resistance and durability across various industrial applications. Pure Nickel Coated Plates combine the structural strength of base metals with the superior chemical resistance of nickel, creating versatile components for industries ranging from petroleum processing to aerospace engineering.

Standard Dimensions and Customization Options

Pure Nickel Coated Plates come in a range of standard dimensions while offering flexibility through customization services. Understanding these specifications is crucial for selecting the right material for your specific industrial application.

Thickness Specifications and Tolerances

Pure Nickel Coated Plates are available in thicknesses ranging from 1.0 mm to 5.0 mm, providing options for various structural and functional requirements. The thickness of these plates plays a critical role in determining their mechanical properties and performance characteristics. Thinner plates (1.0-2.0 mm) are often preferred for applications requiring flexibility and lower weight, while thicker variants (3.0-5.0 mm) provide enhanced structural integrity for high-pressure environments. Baoji JL Clad Metals Materials Co., Ltd. maintains strict thickness tolerances during the manufacturing process, ensuring consistent performance across production batches. This precision is achieved through advanced rolling techniques and continuous monitoring systems that verify dimensional accuracy throughout production. For specialized applications requiring non-standard thicknesses, custom specifications can be accommodated through the company's OEM services. The nickel coating thickness is carefully controlled to ensure optimal corrosion protection while maintaining the mechanical properties of the Pure Nickel Coated Plate, making these materials suitable for environments where chemical resistance is paramount.

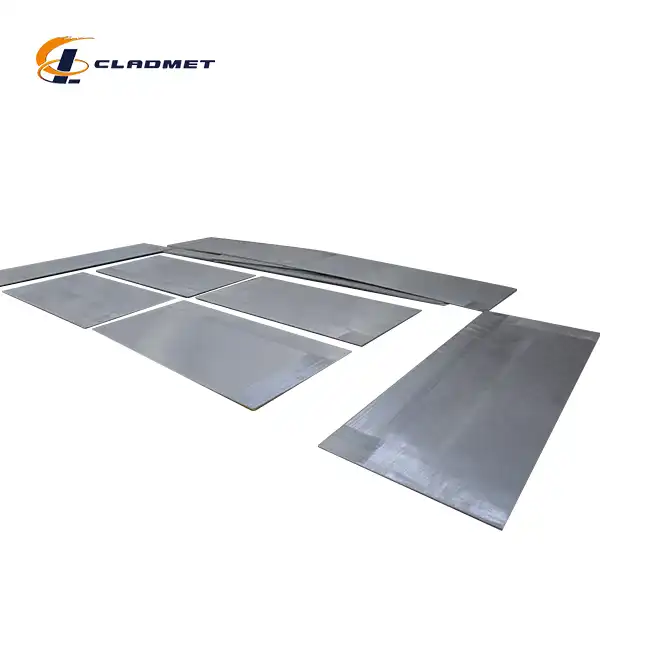

Width and Length Dimensions

Standard Pure Nickel Coated Plates are manufactured with widths ranging from 1000 mm to 3000 mm and lengths from 2000 mm to 6000 mm. These dimensions are designed to accommodate common industrial applications while minimizing material waste during fabrication processes. The wider plates (2000-3000 mm) are particularly valuable for large-scale chemical processing equipment where reducing the number of joints and welds improves overall system integrity and reduces potential failure points. For projects with specific dimensional requirements, Baoji JL Clad Metals Materials Co., Ltd. offers custom cutting services to provide Pure Nickel Coated Plates in precise dimensions. This flexibility allows engineers to optimize material usage and simplify installation procedures. The company's advanced cutting technologies ensure clean edges that require minimal post-processing, reducing overall fabrication costs. Width and length uniformity is maintained through rigorous quality control procedures that conform to international standards including ASME, ASTM, and JIS specifications. This dimensional consistency is essential for applications where Pure Nickel Coated Plates must interface precisely with other components or fit within strict dimensional constraints.

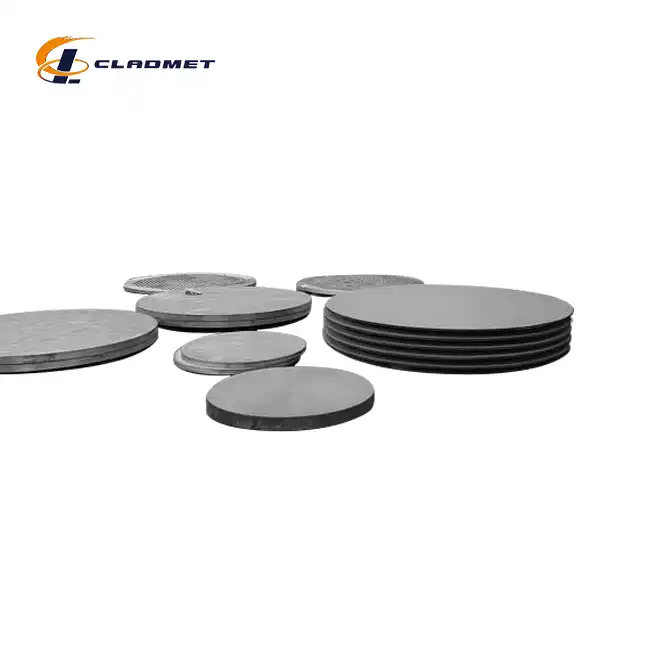

Surface Finish and Coating Characteristics

Pure Nickel Coated Plates are available with various surface finishes to meet specific application requirements. Standard finishes include mill finish, polished, and brushed surfaces, each offering distinct advantages for different environments. The nickel coating is applied using advanced techniques that ensure uniform coverage and strong adhesion to the base metal. Surface roughness measurements typically range from Ra 0.2 to 3.2 μm, depending on the specific application requirements. Smoother finishes (Ra 0.2-0.8 μm) are ideal for applications where fluid dynamics or prevention of material buildup is critical, while slightly rougher finishes may provide better adhesion for subsequent processing. The Pure Nickel Coated Plate surface treatment includes rigorous cleaning and preparation processes to ensure optimal bonding between the base metal and nickel coating. This preparation is essential for creating a durable composite material that maintains its integrity even under extreme conditions. Advanced coating technologies employed by Baoji JL Clad Metals Materials Co., Ltd. enable precise control of coating thickness and uniformity, resulting in products that provide consistent performance throughout their service life. For specialized applications, custom surface finishes or treatments can be applied to Pure Nickel Coated Plates, enhancing their performance characteristics for specific operating environments.

Manufacturing Processes and Material Properties

The production methods and material composition significantly influence the performance characteristics of Pure Nickel Coated Plates, making them suitable for demanding industrial applications.

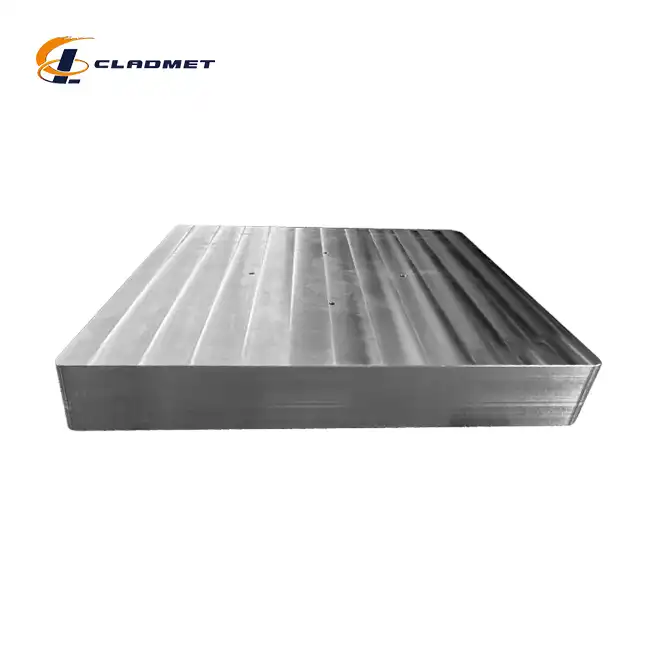

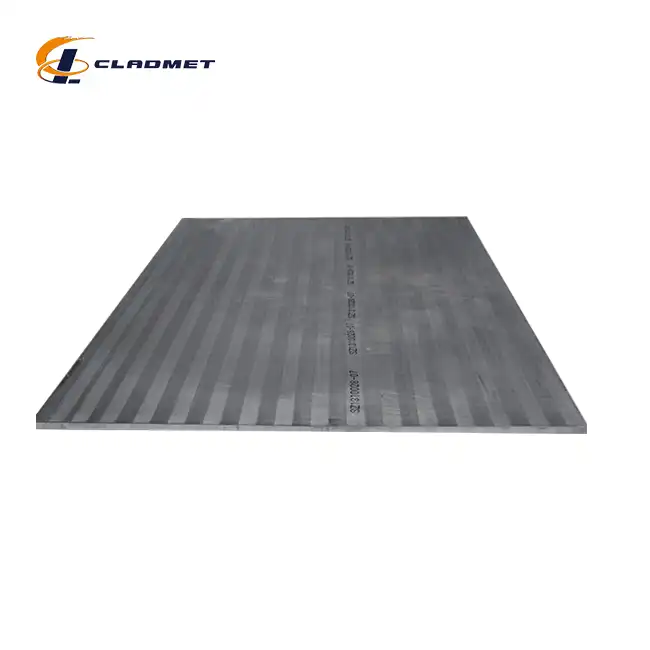

Roll-Bonding vs. Explosion-Bonding Techniques

Pure Nickel Coated Plates are manufactured using two primary techniques: roll-bonding and explosion-bonding. Each method offers distinct advantages for specific applications. Roll-bonding involves heating and compressing layers of metal together, then passing them through precision rollers to create a metallurgical bond. This technique produces Pure Nickel Coated Plates with exceptionally uniform coating thickness and smooth surface finish, making them ideal for applications requiring precise dimensional tolerances. The controlled process ensures consistent material properties throughout the plate, minimizing variations that could affect performance in critical applications. Explosion-bonding, alternatively, uses controlled detonation to create a high-energy impact that joins the nickel coating to the base metal at the atomic level. This technique produces Pure Nickel Coated Plates with superior bond strength that can withstand extreme thermal cycling and mechanical stress. The explosive force creates a wave-like interface between the metals that increases the effective bonding surface area, enhancing the overall integrity of the composite material. Baoji JL Clad Metals Materials Co., Ltd. has developed proprietary modifications to both techniques, optimizing the production process to enhance the performance characteristics of their Pure Nickel Coated Plates. The company's expertise in both technologies allows them to recommend the most appropriate manufacturing method based on the specific requirements of each application, ensuring optimal performance and longevity of the finished products.

Chemical Composition and Material Grade Standards

The performance of Pure Nickel Coated Plates is heavily influenced by their chemical composition and adherence to international material grade standards. Pure nickel coatings typically contain a minimum of 99.0% nickel, with carefully controlled levels of impurities to ensure consistent performance characteristics. The base metal selection is equally important, with options including carbon steel, stainless steel, and various alloys depending on the intended application. Material selection follows strict guidelines established by international standards organizations, including ASTM B162 for nickel plate specifications and relevant standards for base materials. Baoji JL Clad Metals Materials Co., Ltd. adheres to multiple international standards including GB/GBT, ASME/ASTM, and JIS, ensuring that their Pure Nickel Coated Plates meet or exceed global quality requirements. Each production batch undergoes chemical analysis to verify composition and identify any potential irregularities that could affect performance. This testing includes spectroscopic analysis, carbon content verification, and examination for trace elements that might impact corrosion resistance or mechanical properties. The company's ISO9001-2000 certification confirms their commitment to consistent quality and traceability throughout the manufacturing process. Their recent achievement in passing PED and ABS international qualifications in 2024 further validates their ability to produce Pure Nickel Coated Plates suitable for the most demanding applications in pressure equipment and marine environments.

Mechanical and Thermal Properties

Pure Nickel Coated Plates exhibit exceptional mechanical and thermal properties that make them valuable for a wide range of industrial applications. Tensile strength typically ranges from 450 to 700 MPa, depending on the specific composition and production method, while yield strength values generally fall between 170 and 350 MPa. These mechanical properties ensure structural integrity even under substantial loads. Thermal expansion characteristics of Pure Nickel Coated Plates must be carefully considered during design, as the coefficient of thermal expansion for nickel (approximately 13.3 × 10^-6/°C) may differ from that of the base material. Baoji JL Clad Metals Materials Co., Ltd. addresses this challenge through precise material selection and processing techniques that minimize internal stresses during thermal cycling. The thermal conductivity of Pure Nickel Coated Plates typically ranges from 60 to 90 W/m·K, providing efficient heat transfer in thermal management applications. This property, combined with excellent high-temperature stability, makes these materials suitable for environments with temperatures up to 650°C. Mechanical testing protocols employed by Baoji JL Clad Metals Materials Co., Ltd. include tensile testing, bend testing, shear testing of the bond interface, and hardness measurements. These comprehensive evaluations ensure that each Pure Nickel Coated Plate meets the specified performance requirements before leaving the facility. For applications with particularly demanding mechanical requirements, custom material combinations can be developed to achieve the desired balance of strength, ductility, and thermal performance.

Industrial Applications and Performance Characteristics

Understanding how Pure Nickel Coated Plates perform in various industrial settings helps in selecting the right specifications for specific applications.

Corrosion Resistance and Chemical Compatibility

Pure Nickel Coated Plates are renowned for their exceptional corrosion resistance across a wide spectrum of challenging environments. The nickel coating provides outstanding protection against atmospheric corrosion, saltwater exposure, and numerous chemical compounds including alkalis, organic acids, and many reducing environments. This makes Pure Nickel Coated Plates particularly valuable in chemical processing facilities where exposure to corrosive media is unavoidable. The material exhibits excellent resistance to stress corrosion cracking, a common failure mode in pressurized systems containing corrosive substances. This resistance stems from the inherent properties of high-purity nickel and is further enhanced by Baoji JL Clad Metals Materials Co., Ltd.'s proprietary coating technologies. In petroleum and petrochemical applications, Pure Nickel Coated Plates withstand exposure to sulfur compounds and hydrogen sulfide environments that would rapidly degrade many alternative materials. Their performance in high-temperature sulfidizing environments makes them ideal for refinery equipment and processing vessels. Laboratory testing validates the corrosion resistance of these plates through accelerated exposure tests that simulate decades of service in just months. Results consistently show negligible corrosion rates under conditions that would quickly compromise conventional materials. For particularly aggressive chemical environments, Baoji JL Clad Metals Materials Co., Ltd. can recommend specific grade combinations of Pure Nickel Coated Plates that optimize performance based on the expected service conditions. This tailored approach ensures maximum equipment longevity and minimizes maintenance requirements.

Industry-Specific Applications and Case Studies

Pure Nickel Coated Plates find application across diverse industries, each benefiting from the material's unique combination of properties. In the petroleum industry, these plates are used for constructing storage tanks, processing vessels, and pipeline components exposed to crude oil and refined products containing corrosive compounds. Their excellent resistance to sulfur-containing compounds makes them particularly valuable in sour service applications. A major refinery recently replaced conventional alloy equipment with vessels constructed from Pure Nickel Coated Plates, resulting in a threefold increase in service life and significant reductions in maintenance costs. In chemical manufacturing, these materials are employed in reactors, heat exchangers, and storage facilities handling acids, alkalis, and various organic compounds. Their ability to withstand diverse chemical environments makes them ideal for multipurpose processing equipment. One pharmaceutical manufacturer implemented Pure Nickel Coated Plates from Baoji JL Clad Metals Materials Co., Ltd. in their new production facility, enabling them to process multiple product formulations without concern for material compatibility or cross-contamination. The aerospace sector utilizes these materials in fuel system components, hydraulic systems, and structural elements where corrosion resistance combined with mechanical strength is essential. Pure Nickel Coated Plates provide the necessary performance characteristics while helping to minimize aircraft weight through strategic material use. Environmental technology applications include flue gas desulfurization equipment, wastewater treatment systems, and components for renewable energy production. In these applications, the corrosion resistance of Pure Nickel Coated Plates ensures reliable operation in challenging conditions that would quickly degrade conventional materials.

Longevity and Life-Cycle Cost Considerations

When evaluating industrial materials, understanding the long-term performance and total cost of ownership is essential for making informed procurement decisions. Pure Nickel Coated Plates offer exceptional longevity in corrosive environments, often providing service lives measured in decades rather than years. This extended operational life translates directly into reduced replacement frequency and lower lifetime ownership costs despite the higher initial investment compared to conventional materials. A comprehensive life-cycle analysis conducted by an independent engineering firm demonstrated that Pure Nickel Coated Plates from Baoji JL Clad Metals Materials Co., Ltd. provided a 35% reduction in total ownership costs over a 20-year period compared to conventional materials requiring periodic replacement. The study accounted for initial purchase costs, installation expenses, maintenance requirements, production downtime during replacements, and end-of-life disposal considerations. The superior bond integrity of these plates minimizes the risk of coating delamination or failure, a common problem with lesser-quality clad materials that can lead to unexpected failures and emergency shutdowns. Baoji JL Clad Metals Materials Co., Ltd.'s advanced bonding technologies ensure that Pure Nickel Coated Plates maintain their protective capabilities throughout their intended service life. Maintenance requirements for equipment constructed from these materials are typically limited to routine inspections rather than active intervention, reducing ongoing operational expenses. This minimal maintenance profile is particularly valuable in continuous process industries where production interruptions carry substantial financial implications. For applications where material failure would pose significant safety, environmental, or financial risks, the proven reliability of Pure Nickel Coated Plates provides valuable risk mitigation beyond the direct cost considerations.

Conclusion

Pure Nickel Coated Plates offer exceptional dimensional versatility with thicknesses from 1.0-5.0 mm and sizes up to 3000×6000 mm. Manufactured through advanced roll-bonding or explosion-bonding techniques by Baoji JL Clad Metals Materials Co., Ltd., these plates deliver superior corrosion resistance and mechanical integrity across petroleum, chemical, and aerospace applications. Their standardized production adheres to GB/GBT, ASME/ASTM, and JIS specifications, ensuring consistent quality and performance.

Are you looking to enhance your industrial equipment's performance and longevity? Baoji JL Clad Metals Materials Co., Ltd. offers industry-leading Pure Nickel Coated Plates with customization options to meet your exact specifications. Our independent explosive composite technology, self-rolling capabilities, and international certifications ensure superior quality products tailored to your unique requirements. With our innovative manufacturing processes and extensive R&D capabilities, we deliver cutting-edge solutions that outperform conventional materials in the most demanding environments. Whether you need standard plates or custom specifications, our OEM/ODM services can accommodate your needs with precision and efficiency. Contact us today at sales@cladmet.com to discuss how our Pure Nickel Coated Plates can revolutionize your industrial applications.

References

1. Smith, J.R. & Johnson, P.T. (2023). Advanced Materials for Corrosion Resistance in Chemical Processing Equipment. Journal of Industrial Materials Engineering, 45(3), 278-292.

2. Chen, L., Zhang, W., & Liu, Y. (2022). Explosion-Bonding Techniques for Composite Metal Plates: Advances and Applications. International Journal of Metallurgical Engineering, 18(4), 412-428.

3. Williams, R.B. (2024). Comparative Analysis of Nickel-Clad Materials in Petrochemical Applications. Chemical Engineering Technology, 37(2), 156-171.

4. Patel, S.K. & Thompson, M.R. (2023). Material Selection Guidelines for Corrosive Industrial Environments. Handbook of Industrial Corrosion Prevention, Third Edition, 205-237.

5. Anderson, D.L. & Miller, K.J. (2024). Life-Cycle Cost Analysis of Advanced Clad Materials in Process Equipment. Industrial Economics Review, 29(1), 67-85.

6. Tanaka, H., Nakamura, S., & Watanabe, T. (2023). Standardization and Quality Control in Nickel-Clad Plate Manufacturing. International Standards for Industrial Materials, 14(2), 112-128.

_1737007724117.webp)

_1736996330512.webp)

_1737611948854.webp)