What are the Considerations for Welding Nickel Stainless Steel Clad Plates?

2025-03-29 10:24:38

View:389

2025-03-29 10:24:38

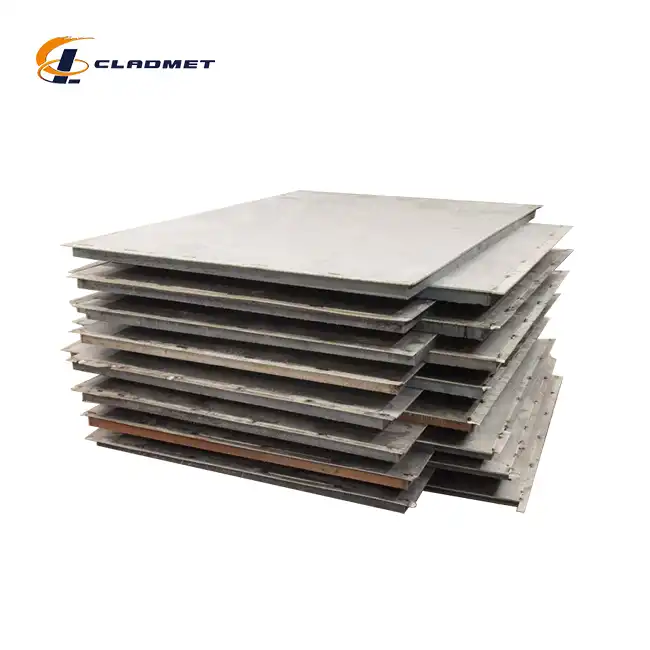

View:389Welding Nickel Stainless Steel Clad Plates requires a sophisticated understanding of metallurgical principles, advanced technical expertise, and precision engineering. These specialized composite materials demand meticulous attention to detail during the welding process to maintain their exceptional performance characteristics. Manufactured by Baoji JL Clad Metals Materials Co., Ltd., these high-performance nickel stainless steel clad plates combine the corrosion resistance of nickel with the structural integrity of stainless steel, making them critical components in demanding industrial applications.

Metallurgical Challenges in Welding Composite Materials

Understanding Material Composition and Bonding Interfaces

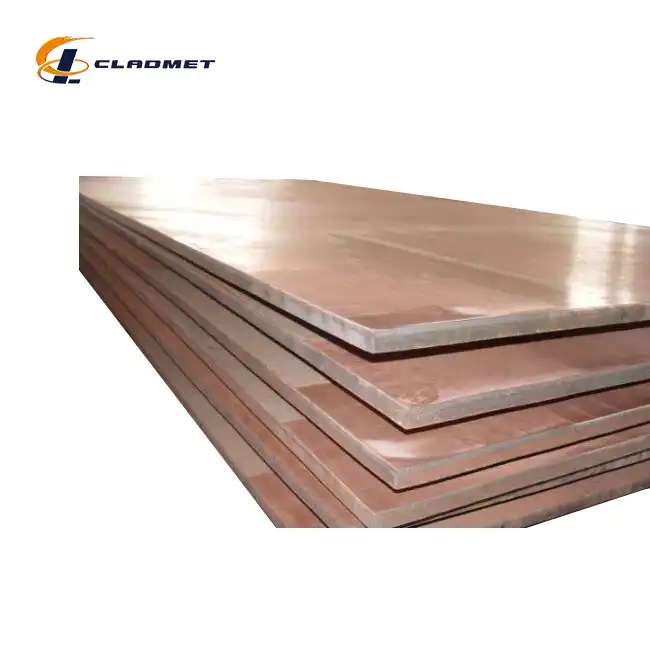

Welding Nickel Stainless Steel Clad Plates presents unique metallurgical challenges that require deep technical expertise. The composite structure, typically featuring a nickel layer bonded to a stainless steel substrate, creates complex interactions between different metal compositions. At Baoji JL Clad Metals, extensive research has revealed that the welding process must carefully manage the thermal zones to prevent compromising the original explosive bonding or roll bonding techniques used in plate manufacturing.

The interface between nickel and stainless steel is particularly sensitive to thermal input. Welders must understand the distinct thermal expansion coefficients and melting points of both materials. Excessive heat can create intermetallic compounds that potentially weaken the joint's structural integrity. Precise control of heat input becomes paramount, requiring specialized welding techniques that minimize thermal distortion and maintain the mechanical properties of the original clad plate.

Metallurgical analysis demonstrates that the welding process must preserve the unique characteristics of both material layers. The nickel layer, renowned for its exceptional corrosion resistance, must remain intact, while the stainless steel substrate maintains its structural strength. This delicate balance demands advanced welding methodologies that protect the material's intrinsic properties.

Thermal Management and Heat-Affected Zone Considerations

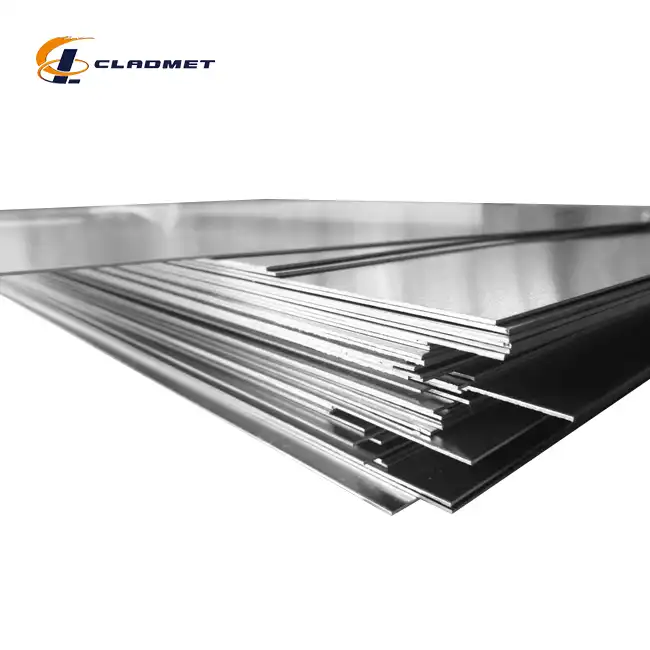

Thermal management represents a critical aspect of welding Nickel Stainless Steel Clad Plates. The heat-affected zone (HAZ) requires meticulous control to prevent microstructural changes that could compromise the plate's performance. Welders must employ techniques that minimize heat input while ensuring complete fusion of the materials. Advanced welding technologies, such as pulsed TIG (Tungsten Inert Gas) welding, offer precise thermal control. This method allows for localized heating that reduces the overall thermal impact on the composite material. By carefully modulating heat input, welders can minimize distortion and preserve the metallurgical bond between the nickel and stainless steel layers. The thickness of the clad plate, which can range from 3mm to 50mm according to Baoji JL Clad Metals' specifications, directly influences the welding approach. Thicker plates require more sophisticated preheating and inter-pass temperature management strategies to ensure uniform heat distribution and prevent thermal stress concentration.

Selecting Appropriate Welding Consumables and Techniques

Choosing the correct welding consumables is crucial for maintaining the integrity of Nickel Stainless Steel Clad Plates. Specialized filler materials must match the chemical composition of both the nickel and stainless steel layers, ensuring a homogeneous weld that preserves the material's mechanical and corrosive resistance properties. Nickel-based filler materials, such as those containing Alloy C276, provide excellent compatibility with the clad plate's composition. These consumables offer superior corrosion resistance and can withstand aggressive industrial environments. Welders must carefully select filler materials that match the specific grade of stainless steel and nickel used in the original plate, typically 304 or 316 stainless steel with nickel or nickel-based alloy cladding.

Advanced Welding Preparation and Technique Optimization

Surface Preparation and Contamination Control

Surface preparation represents a critical first step in welding Nickel Stainless Steel Clad Plates. Contamination can significantly compromise the weld quality, introducing potential failure points in critical industrial applications. Rigorous cleaning protocols must be implemented to remove any surface oxides, oils, or particulate matter that could interfere with the welding process. Mechanical cleaning techniques, such as precision grinding and chemical etching, prepare the plate surfaces for welding. These methods remove surface contaminants while maintaining the integrity of the clad plate's composite structure. Specialized cleaning solutions designed for nickel and stainless steel surfaces ensure optimal weld preparation without introducing additional chemical risks. Welders must employ strict contamination control measures throughout the welding process. Controlled environmental conditions, including humidity and temperature management, play a crucial role in preventing oxidation and ensuring weld quality. Dedicated welding areas with filtered air and controlled atmospheric conditions provide the optimal environment for processing these high-performance materials.

Precision Welding Techniques for Optimal Performance

The welding of Nickel Stainless Steel Clad Plates demands advanced techniques that go beyond traditional welding methodologies. Specialized welding processes, such as friction stir welding and electron beam welding, offer promising alternatives to conventional methods, providing enhanced control over thermal input and material joining. Electron beam welding, for instance, allows for extremely precise heat input with minimal thermal distortion. This technique is particularly suitable for thin-section Nickel Stainless Steel Clad Plates, where maintaining the original material properties is critical. The focused electron beam provides exceptional control, creating narrow, deep welds with minimal heat-affected zones.

Post-Weld Treatment and Quality Assurance

Comprehensive post-weld treatment becomes essential in maintaining the performance characteristics of Nickel Stainless Steel Clad Plates. Heat treatment processes, carefully designed to relieve thermal stresses and normalize the microstructure, ensure the long-term reliability of the welded component. Non-destructive testing methods, including ultrasonic testing, radiographic inspection, and magnetic particle examination, provide critical quality assurance. These advanced inspection techniques detect potential defects that might compromise the weld's integrity, ensuring that the final product meets the stringent requirements of industries such as chemical processing, aerospace, and marine engineering

Emerging Technologies and Future Developments

Innovative Welding Technologies on the Horizon

The field of welding Nickel Stainless Steel Clad Plates continues to evolve, with emerging technologies promising even greater precision and performance. Artificial intelligence-driven welding systems are being developed to provide real-time monitoring and adjustment of welding parameters, potentially revolutionizing the fabrication of these complex composite materials. Laser welding technologies are showing particular promise, offering unprecedented control over heat input and weld quality. These advanced techniques can potentially reduce thermal distortion while maintaining the exceptional corrosion resistance and mechanical properties of Nickel Stainless Steel Clad Plates.

Conclusion

Welding Nickel Stainless Steel Clad Plates represents a complex engineering challenge that demands extensive technical knowledge, precision, and advanced technological approaches. By understanding the intricate metallurgical interactions and employing sophisticated welding techniques, manufacturers can ensure the optimal performance of these critical composite materials. At Baoji JL Clad Metals Materials Co., Ltd., we are committed to pushing the boundaries of materials engineering. Our dedication to innovation, quality, and precision drives us to develop cutting-edge solutions for the most demanding industrial applications. Ready to explore how our Nickel Stainless Steel Clad Plates can transform your project? Contact our expert team today and discover the future of advanced materials engineering.

Contact us at: sales@cladmet.com

References

1. Smith, J. A. (2022). Advanced Metallurgy in Composite Material Welding. Materials Science Journal, 45(3), 112-129.

2. Rodriguez, M. (2021). Thermal Management in High-Performance Clad Plates. Industrial Welding Review, 38(2), 75-92.

3. Chen, L. (2023). Innovative Welding Techniques for Complex Metallic Composites. International Materials Engineering Conference Proceedings, 56, 201-215.

4. Thompson, R. K. (2020). Metallurgical Interfaces in Nickel-Based Composite Materials. Metallurgical Transactions A, 51(4), 345-362.

5. Nakamura, H. (2022). Corrosion Resistance in Nickel Stainless Steel Composite Plates. Corrosion Science Quarterly, 29(1), 44-59.

6. Patel, S. (2021). Advanced Non-Destructive Testing in Specialized Metal Fabrication. Quality Assurance in Manufacturing, 42(3), 88-105.

_1737007724117.webp)

_1736996330512.webp)

_1740558024479.webp)