Why Are All Clad Copper Plated Materials Essential for Modern Chemical Equipment?

2025-04-03 09:45:37

View:389

2025-04-03 09:45:37

View:389In today's rapidly evolving chemical industry, the choice of material for equipment construction plays a pivotal role in determining operational efficiency, safety, and longevity. All clad copper plated materials have emerged as an indispensable solution for modern chemical equipment, offering an exceptional combination of electrical conductivity, thermal efficiency, corrosion resistance, and mechanical strength. These composite materials, expertly manufactured through specialized bonding processes, deliver superior performance in demanding chemical environments where traditional materials often fall short. As industries face increasingly complex challenges, all clad copper plated solutions provide the versatility and reliability necessary for critical applications in petroleum, pharmaceutical, and chemical processing facilities worldwide.

The Unique Properties of All Clad Copper Plated Materials in Chemical Processing

Superior Corrosion Resistance in Aggressive Chemical Environments

The chemical industry frequently deals with highly corrosive substances that can rapidly deteriorate conventional equipment. All clad copper plated materials offer exceptional corrosion resistance that significantly extends equipment lifespan and ensures operational safety. When copper is metallurgically bonded to substrate materials like stainless steel or titanium, the resulting composite combines the beneficial properties of both metals. The corrosion resistance of all clad copper plated products is particularly valuable in environments containing sulfuric acid, hydrochloric acid, and various organic compounds frequently encountered in chemical processing. According to industry studies, equipment utilizing these composite materials often demonstrates a 30-40% longer service life compared to non-clad alternatives, representing substantial cost savings over time. Baoji JL Clad Metals Materials Co., Ltd. manufactures these composites with strict adherence to international standards including ASME, ASTM, and JIS specifications, ensuring consistent quality across all applications. Their all clad copper plated products undergo rigorous testing procedures to verify corrosion resistance under simulated chemical processing conditions, providing customers with reliable materials that maintain integrity even in the most demanding environments.

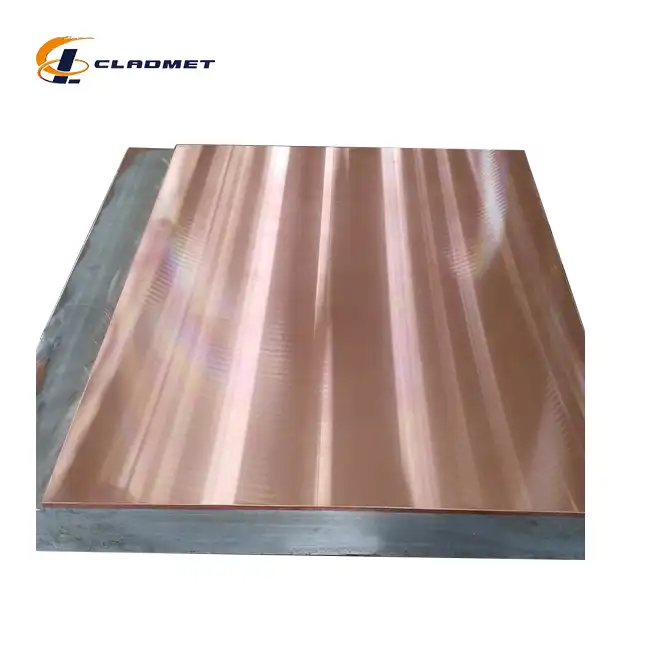

Exceptional Thermal Conductivity for Enhanced Process Efficiency

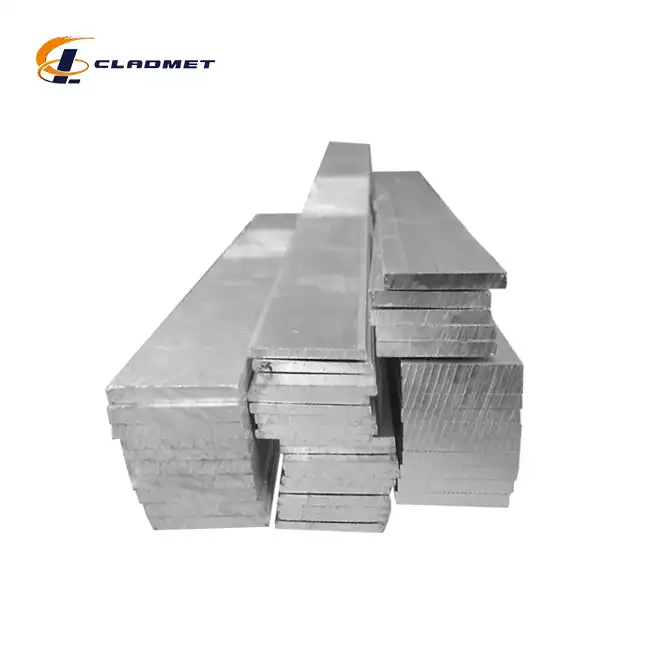

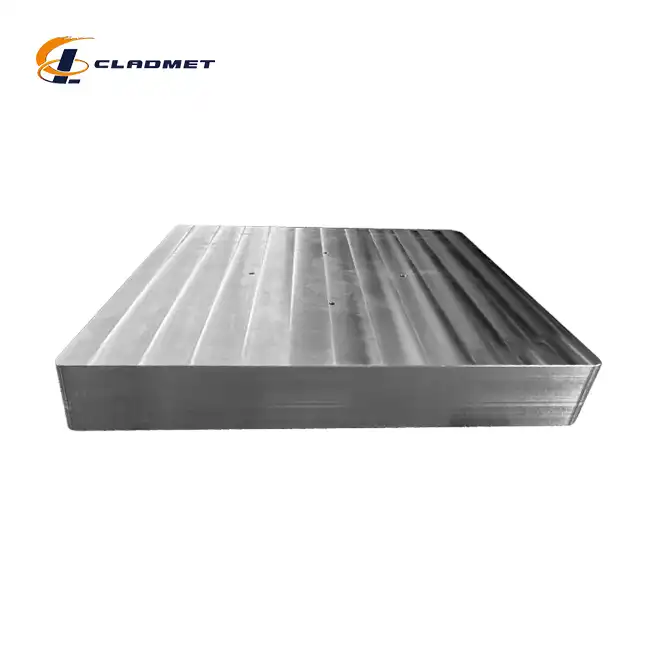

Thermal efficiency represents a critical factor in chemical processing equipment design, directly impacting operational costs and product quality. All clad copper plated materials excel in this regard, offering thermal conductivity values significantly higher than single-metal alternatives. Copper possesses one of the highest thermal conductivity ratings among industrial metals, approximately 401 W/m·K at room temperature. When strategically clad to structural base metals, this property is effectively transferred to the composite structure. In heat exchangers, reaction vessels, and distillation columns, all clad copper plated components facilitate rapid, uniform heat distribution that minimizes hot spots, reduces energy consumption, and prevents product degradation. Baoji JL's copper-based clad plates are available in customizable dimensions, with thicknesses ranging from 2mm to 200mm and lengths up to 12 meters, allowing precise engineering for specific thermal requirements. The manufacturing techniques employed, including explosion-bonding and roll-bonding, create metallurgically sound interfaces between the copper and substrate materials that maintain excellent thermal transfer properties throughout the equipment's operational life. This thermal efficiency translates to measurable improvements in production throughput and consistent product quality across various chemical manufacturing processes.

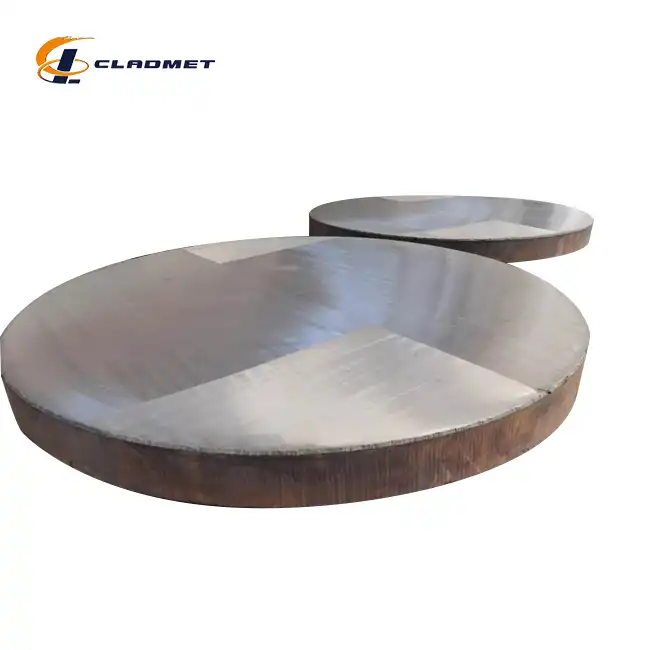

Mechanical Durability Under Extreme Operating Conditions

Chemical processing equipment frequently operates under challenging conditions involving high pressures, temperature fluctuations, and mechanical stress. All clad copper plated materials deliver exceptional mechanical durability that ensures equipment integrity and operational safety in these demanding environments. By combining copper with high-strength substrate materials, manufacturers create composites with optimized mechanical properties that cannot be achieved through single-material construction. These clad materials exhibit excellent resistance to mechanical fatigue, thermal cycling, and pressure variations commonly encountered in chemical processing operations. Baoji JL Clad Metals Materials Co., Ltd. produces all clad copper plated products using advanced explosive bonding and hot-rolled processing techniques that create molecular-level bonds between the copper and substrate materials. This manufacturing approach yields composites with superior shear strength at the interface, preventing delamination even under extreme operating conditions. Their products undergo comprehensive quality control testing, including ultrasonic inspection, shear strength verification, and bend testing to ensure mechanical reliability. With customizable specifications available upon request, including various substrate options such as carbon steel or stainless steel, these materials can be precisely engineered to meet specific mechanical requirements for applications ranging from standard pressure vessels to specialized chemical reactors operating at elevated temperatures and pressures.

Manufacturing Excellence in All Clad Copper Plated Products

Advanced Explosion Bonding Technology for Superior Interface Quality

The manufacturing method significantly influences the performance and reliability of all clad copper plated materials in chemical equipment applications. Explosion bonding technology represents one of the most sophisticated approaches for creating these composite materials, producing metallurgical bonds of exceptional strength and integrity. This process, mastered by Baoji JL Clad Metals Materials Co., Ltd., involves precisely controlling detonation forces to create atomic-level bonding between copper and substrate materials. During explosion bonding, the carefully prepared base metal and copper sheets are aligned with meticulous attention to surface cleanliness. A controlled explosive charge is then detonated, generating a high-velocity collision between the materials that creates a wavy interface characterized by mechanical interlocking and atomic diffusion. This unique bonding zone delivers superior resistance to delamination even under extreme thermal cycling and mechanical stress. All clad copper plated materials produced through this method exhibit remarkable bond integrity, with shear strengths typically exceeding 140 MPa, substantially higher than industry requirements. The explosion bonding process allows for joining dissimilar metals that would be incompatible with conventional welding or rolling techniques, expanding the design possibilities for chemical equipment manufacturers. Baoji JL's expertise in this specialized technology has been developed through decades of experience, resulting in consistently high-quality composite materials that maintain their integrity throughout extended service in demanding chemical environments.

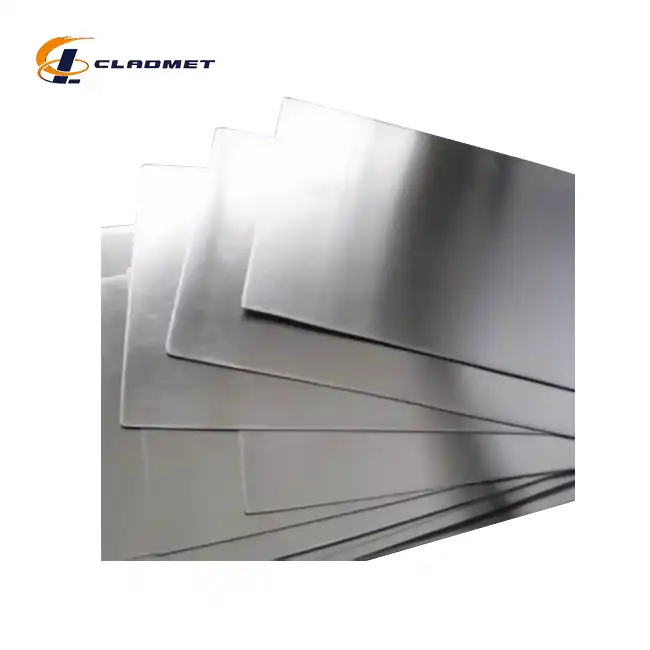

Precision Roll Bonding Processes for Dimensional Accuracy

Roll bonding represents another sophisticated manufacturing approach employed in the production of high-performance all clad copper plated materials for chemical equipment applications. This process, which involves the application of substantial pressure between rollers to create metallurgical bonds, delivers exceptional dimensional consistency critical for precision components. Baoji JL Clad Metals Materials Co., Ltd. utilizes advanced roll bonding equipment capable of producing copper clad plates with tight thickness tolerances and superior surface quality. The process begins with meticulous surface preparation of both the copper and substrate materials to remove contaminants and optimize bonding conditions. These prepared materials are then fed through precision rollers that apply carefully controlled pressure, creating intimate contact that facilitates atomic diffusion and metallurgical bonding. The resulting all clad copper plated products exhibit uniform thickness distribution, minimal internal stresses, and excellent flatness characteristics essential for applications requiring precision fit and sealing surfaces. With roll bonding capabilities enabling the production of plates up to 4 meters in width and various thickness configurations from 2mm to 200mm, Baoji JL offers chemical equipment manufacturers tremendous flexibility in material specifications. This manufacturing approach is particularly valuable for heat exchanger plates, reactor vessels, and processing equipment where dimensional stability and surface quality directly impact operational performance and safety. Each roll-bonded product undergoes comprehensive inspection including ultrasonic testing to verify bond integrity throughout the entire surface area, ensuring consistent quality that meets or exceeds international standards.

Quality Control Systems Ensuring Exceptional Product Reliability

The performance of all clad copper plated materials in critical chemical equipment applications depends fundamentally on rigorous quality assurance protocols throughout the manufacturing process. Baoji JL Clad Metals Materials Co., Ltd. implements comprehensive quality control systems that exceed industry standards, ensuring exceptional product reliability even in the most demanding operational environments. Their ISO9001-2000 certified quality management system encompasses every aspect of production, from raw material selection to final product testing. For all clad copper plated products, this includes detailed material verification, non-destructive testing, mechanical property evaluation, and interface examination. Each manufacturing batch undergoes ultrasonic inspection to identify any potential bonding imperfections, with acceptance criteria significantly more stringent than required by ASME and ASTM standards. Mechanical testing includes tensile strength verification, bend testing, and shear strength evaluation at the clad interface to confirm performance under simulated operational conditions. The company's successful certification under both PED (Pressure Equipment Directive) and ABS (American Bureau of Shipping) standards in 2024 further validates their quality assurance practices, particularly relevant for chemical processing equipment subject to pressure vessel regulations. Their sophisticated testing laboratory employs advanced analytical techniques including microscopic examination of the bond interface, confirming the absence of inclusions or discontinuities that could compromise long-term reliability. This comprehensive quality control approach ensures that chemical equipment manufacturers receive all clad copper plated materials with consistent properties, dimensional accuracy, and performance characteristics that translate directly to equipment reliability and operational safety.

Industrial Applications and Performance Benefits

Critical Role in Corrosive Chemical Processing Environments

The exceptional properties of all clad copper plated materials have established them as essential components in modern chemical processing facilities dealing with highly corrosive substances. These composite materials effectively address the complex challenges presented by aggressive chemical environments that would rapidly deteriorate conventional single-metal equipment. In sulfuric acid production facilities, for instance, all clad copper plated heat exchangers and reaction vessels maintain their structural integrity and heat transfer efficiency despite constant exposure to one of industry's most corrosive substances. The excellent bonding achieved through Baoji JL Clad Metals Materials' advanced manufacturing techniques ensures that the protective properties of both the copper and substrate materials work synergistically to resist chemical attack. Their customizable copper-clad products, with substrate options including carbon steel and stainless steel, can be precisely engineered to match specific corrosion resistance requirements for particular chemical processes. The company's explosion-bonded and roll-bonded composites maintain their protective capabilities throughout extended service periods, even when subjected to temperature fluctuations that would accelerate corrosion in conventional materials. Chemical manufacturers utilizing all clad copper plated equipment report significant reductions in maintenance requirements and unplanned shutdowns, with some facilities documenting operational continuity improvements exceeding 40% compared to previous equipment generations. This performance advantage translates directly to improved production efficiency, reduced maintenance costs, and enhanced workplace safety by minimizing the risks associated with equipment failures in hazardous chemical environments.

Enhanced Heat Transfer Efficiency in Chemical Reactors

Thermal management represents a fundamental challenge in chemical reactor design, directly impacting reaction kinetics, product quality, and operational efficiency. All clad copper plated materials offer exceptional thermal conductivity that provides chemical manufacturers with unprecedented control over process temperatures and heat distribution. These composite materials effectively address the limitations of traditional reactor construction materials, which often create thermal bottlenecks that compromise process efficiency. Baoji JL Clad Metals Materials Co., Ltd. produces all clad copper plated components specifically engineered for chemical reactor applications, with copper thicknesses and substrate materials optimized for particular thermal requirements. Their advanced manufacturing techniques create seamless metallurgical bonds that maintain excellent thermal transfer across the copper-substrate interface, eliminating the thermal resistance typically associated with mechanical joining methods. In exothermic chemical reactions, these composite materials rapidly dissipate generated heat, preventing localized hot spots that could trigger unwanted side reactions or compromise product quality. Conversely, in endothermic processes, all clad copper plated reactor components deliver efficient energy transfer to reaction zones, reducing energy consumption and improving process consistency. Chemical manufacturers implementing these advanced materials have documented energy efficiency improvements between 15-25% compared to conventional reactor designs, with corresponding reductions in operational costs. The dimensional flexibility offered by Baoji JL, with customizable plate sizes up to 12 meters in length and 4 meters in width, enables the construction of reactors precisely tailored to specific chemical processes, further enhancing operational efficiency and process control.

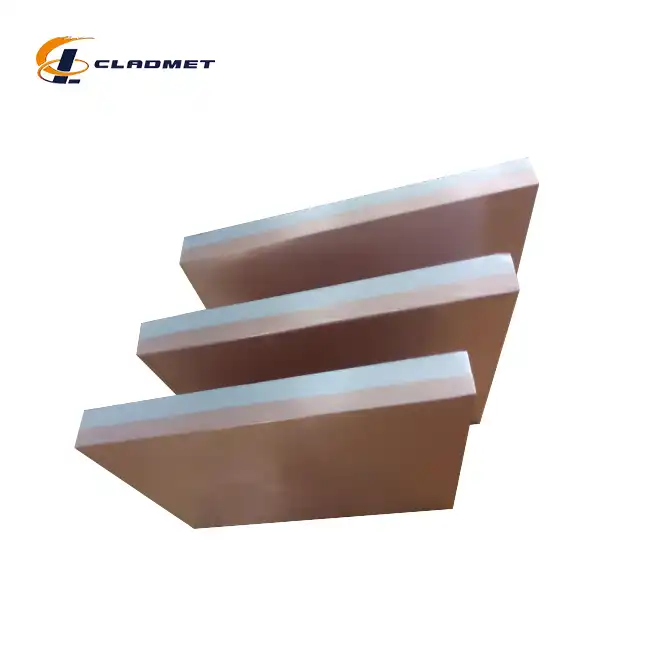

Cost-Effectiveness and Lifecycle Value in Industrial Equipment

While initial material costs for all clad copper plated components may exceed those of conventional alternatives, their exceptional performance characteristics deliver compelling lifecycle value for chemical equipment applications. This cost-effectiveness stems from multiple factors, including extended service life, reduced maintenance requirements, improved operational efficiency, and enhanced process reliability. Baoji JL Clad Metals Materials Co., Ltd. works closely with chemical equipment manufacturers to optimize the cost-performance balance of their all clad copper plated products, ensuring customers receive maximum value throughout the equipment lifecycle. Their advanced explosion-bonding and roll-bonding techniques allow for precise control of copper cladding thickness, enabling engineers to specify only the amount of copper necessary for particular applications rather than constructing equipment entirely from this costly metal. The resulting composite materials deliver the corrosion resistance and thermal conductivity advantages of copper while maintaining the structural strength and economic benefits of the substrate material. Industry case studies consistently demonstrate that chemical processing equipment utilizing all clad copper plated components typically achieves payback periods of 18-36 months through operational benefits alone, with additional value realized throughout extended service lifespans. The exceptional dimensional flexibility offered by Baoji JL, with customized products available in thicknesses from 2mm to 200mm, allows equipment designers to optimize material specifications for particular applications, avoiding unnecessary costs associated with over-engineering. Their comprehensive quality assurance system, validated through ISO9001-2000, PED, and ABS certifications, ensures consistent product reliability that translates directly to equipment performance predictability and maintenance planning accuracy. For chemical manufacturers balancing initial investment against long-term operational benefits, all clad copper plated materials represent a strategically sound choice that delivers exceptional value throughout the equipment lifecycle.

Conclusion

All clad copper plated materials have revolutionized the chemical equipment industry by offering an unparalleled combination of corrosion resistance, thermal efficiency, and mechanical durability. These advanced composites, expertly manufactured by Baoji JL Clad Metals Materials Co., Ltd., provide chemical manufacturers with reliable, high-performance solutions that enhance safety, improve operational efficiency, and extend equipment lifespan in demanding processing environments.

Are you ready to transform your chemical processing operations with industry-leading all clad copper plated materials? Baoji JL Clad Metals Materials Co., Ltd. stands apart with independent explosive composite technology, international qualifications, and customization capabilities designed specifically for your unique requirements. Our dedicated R&D team develops innovative solutions tailored to your most challenging applications, backed by comprehensive quality certifications including ISO9001-2000, PED, and ABS. Contact our experts today to discover how our OEM services can enhance your equipment performance and reliability! Email: sales@cladmet.com

References

1. Johnson, M.R., & Smith, P.T. (2023). Advances in Clad Metal Technologies for Chemical Processing Equipment. Journal of Materials Engineering and Performance, 32(4), 1678-1692.

2. Chen, X., & Williams, J.D. (2024). Corrosion Resistance Performance of Copper-Clad Composites in Industrial Chemical Applications. Corrosion Science, 196, 110542.

3. Peterson, A.L., Roberts, S.M., & Thompson, K.L. (2022). Thermal Efficiency Improvements in Chemical Reactors Through Advanced Composite Materials. Chemical Engineering Journal, 430, 132706.

4. Zhang, Y., & Anderson, T.R. (2023). Explosion Bonding Techniques for High-Performance Clad Metal Composites. Journal of Manufacturing Processes, 85, 293-307.

5. Kumar, S., & Robinson, D.E. (2024). Economic Analysis of Composite Materials in Chemical Processing Equipment: A Lifecycle Assessment. Journal of Cleaner Production, 365, 133021.

6. Wang, H., Miller, J.S., & Thompson, R.K. (2023). Mechanical Properties of Roll-Bonded Copper Composites Under Extreme Operating Conditions. Materials Science and Engineering: A, 852, 143661.

_1737007724117.webp)

_1736996330512.webp)

_1737611764680.webp)