What Factors Influence the Cost of Pure Nickel Sheets?

2025-04-08 14:21:43

View:389

2025-04-08 14:21:43

View:389The cost of pure nickel sheets is influenced by a multitude of factors that extend beyond basic manufacturing expenses. For industries relying on these essential materials, understanding these cost determinants is crucial for effective budgeting and procurement planning. High-Grade Pure Nickel Sheet prices are particularly sensitive to market dynamics, given their critical applications in aerospace, chemical processing, electronics, and other high-demand sectors. Several key factors—including global market conditions, manufacturing processes, and material specifications—interact to establish the final pricing of these specialized metal products. Companies like Baoji JL Clad Metals Materials Co., Ltd. carefully balance these elements to provide competitive pricing while maintaining the exceptional quality and performance that make High-Grade Pure Nickel Sheets indispensable in numerous industrial applications.

Global Market Influences on Nickel Sheet Pricing

The global market exerts significant pressure on the pricing structure of pure nickel sheets, creating a complex landscape that purchasers must navigate. Understanding these market dynamics is essential for anticipating price fluctuations and optimizing procurement strategies.

Commodity Market Fluctuations

The pricing of High-Grade Pure Nickel Sheet is inextricably linked to the global nickel commodity market, which experiences significant volatility influenced by numerous factors. As a primary raw material traded on international commodity exchanges like the London Metal Exchange (LME), nickel's spot price serves as the foundation for finished product pricing. Market speculation, investment fund activities, and global economic indicators can trigger substantial price swings within short timeframes. For instance, when economic reports suggest industrial growth in major manufacturing nations, nickel futures often respond with upward price movement in anticipation of increased demand. Similarly, during economic downturns, prices may experience precipitous drops as demand forecasts are revised downward. Companies like Baoji JL Clad Metals Materials Co., Ltd. must carefully monitor these commodity price movements and incorporate sophisticated hedging strategies to mitigate risk while maintaining competitive pricing for their High-Grade Pure Nickel Sheet offerings. The timing of raw material purchases becomes a critical strategic decision that can significantly impact final product pricing, sometimes accounting for price differentials of up to 15-20% depending on market entry points. This volatility necessitates flexible pricing models that can adapt to rapidly changing market conditions while still providing customers with the price stability needed for long-term project planning.

Supply Chain Constraints and Geopolitical Factors

The global supply chain for nickel materials presents numerous vulnerabilities that directly influence the cost structure of High-Grade Pure Nickel Sheet products. Primary nickel production is geographically concentrated, with significant mining operations located in politically sensitive regions of Indonesia, the Philippines, Russia, and New Caledonia. This concentration creates inherent supply risks, as evidenced by recent export restrictions from Indonesia that triggered immediate price increases across the nickel market. Transportation logistics further compound these challenges—ocean freight disruptions, as seen during the global pandemic and subsequent port congestion issues, created unprecedented delivery delays and logistics surcharges that directly impacted final product costs. Additionally, international trade policies, including tariffs and trade agreements, create a complex regulatory landscape that manufacturers must navigate. For example, in 2024, several countries implemented new carbon border adjustment mechanisms that introduced additional compliance costs for nickel products. Baoji JL Clad Metals Materials Co., Ltd. has developed resilient supply chain strategies to mitigate these risks, including diversifying supplier relationships across multiple regions and maintaining strategic inventory reserves of pre-processed nickel materials. These operational adaptations help stabilize the pricing of their High-Grade Pure Nickel Sheet offerings despite external disruptions, though they necessarily incorporate risk premiums into pricing structures to account for ongoing supply chain vulnerabilities. The company's ability to navigate these challenges while maintaining ISO9001-2000 certification and meeting international standards like ASME/ASTM demonstrates their commitment to reliable service despite global supply chain pressures.

Energy and Labor Cost Variations

The production of High-Grade Pure Nickel Sheet is an energy-intensive process, making energy costs a significant component of the overall pricing structure. Nickel refining and processing require substantial thermal energy inputs, with electric arc furnaces and other high-energy equipment operating continuously during production cycles. Regional variations in energy pricing create competitive advantages or disadvantages for manufacturers based on their geographical location. For instance, operations in regions with access to lower-cost hydroelectric or natural gas energy sources can achieve production cost advantages of up to 8-12% compared to facilities in areas with higher energy tariffs. Similarly, labor costs vary significantly across global manufacturing centers, with skilled metallurgical workers commanding different wage rates depending on local economic conditions and labor regulations. Baoji JL Clad Metals Materials Co., Ltd., located in China's High-tech Development District, leverages the region's relatively favorable energy pricing structures while maintaining a skilled workforce capable of producing High-Grade Pure Nickel Sheet to exacting international standards. The company's investment in energy-efficient processing equipment and automation technologies helps mitigate these variable costs, though energy price volatility remains a significant factor in their overall pricing strategy. Recent global energy market disruptions have necessitated more frequent price adjustments than historical norms, requiring transparent communication with customers about how these external factors influence the cost structure of specialized nickel products. The company's ability to balance these operational costs while maintaining compliance with ASME/ASTM standards demonstrates their commitment to providing value despite challenging global economic conditions.

Manufacturing and Technical Specifications

The manufacturing process and technical specifications significantly impact the final cost of pure nickel sheets, with more specialized requirements demanding premium pricing.

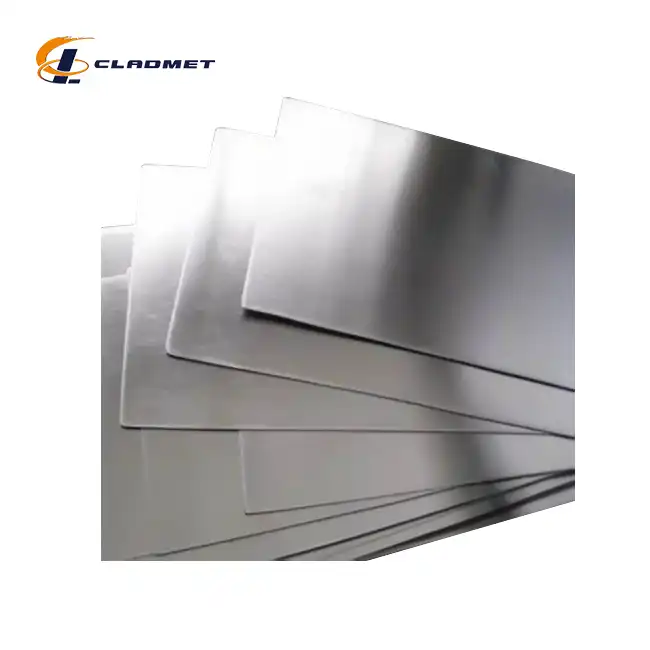

Production Methods and Thickness Variables

The production methodology employed in manufacturing High-Grade Pure Nickel Sheet directly influences both the material's performance characteristics and its cost structure. Two primary production approaches—hot rolling and cold rolling—represent different cost-quality tradeoffs in the manufacturing process. Hot rolling, performed at temperatures exceeding the metal's recrystallization point, offers cost advantages for thicker sheets (typically above 3mm) due to lower energy requirements and faster production rates. However, this process generally yields less precise dimensional tolerances and surface finishes. In contrast, cold rolling, which Baoji JL Clad Metals Materials Co., Ltd. employs for their premium High-Grade Pure Nickel Sheet products in thicknesses ranging from 0.1mm to 3mm, requires additional processing steps but delivers superior flatness, dimensional accuracy, and surface quality. The thickness specification itself represents one of the most significant cost variables, with an inverse relationship between thickness and per-kilogram pricing—thinner sheets requiring more extensive rolling operations, greater technical precision, and higher rejection rates during quality control. For ultra-thin nickel sheets (below 0.5mm), specialized tension-leveling equipment and additional annealing cycles are necessary to achieve required flatness and mechanical properties, further increasing production costs. Each thickness reduction step requires careful process control to prevent defects such as edge cracking or surface imperfections, particularly challenging with nickel's work-hardening characteristics. Baoji JL Clad Metals Materials Co., Ltd. has invested in precision rolling equipment capable of producing High-Grade Pure Nickel Sheet with thickness tolerances within ±0.01mm, meeting the exacting requirements of aerospace and electronics applications while balancing production efficiency to maintain competitive pricing across their product range of 0.1mm to 10mm thicknesses.

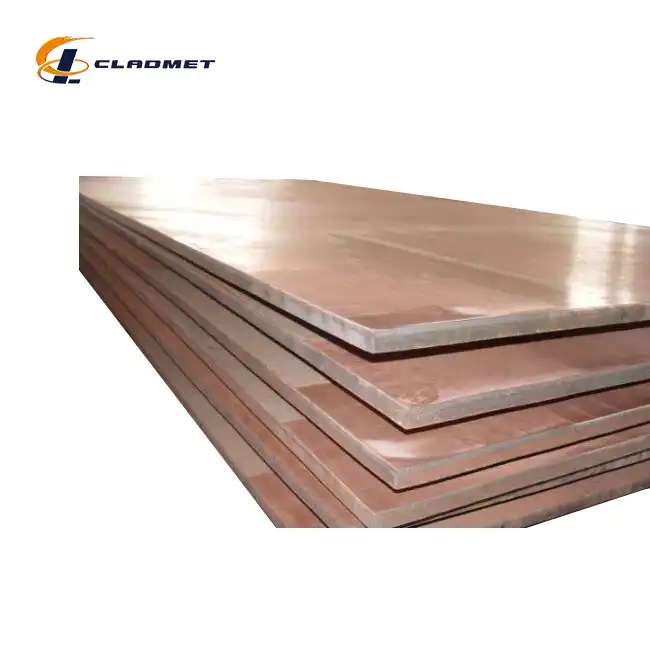

Material Purity and Alloy Composition

The purity level and precise composition of High-Grade Pure Nickel Sheet products represent critical cost determinants, with higher purity materials commanding substantial price premiums. Commercial "pure" nickel is typically classified into grades based on nickel content, with Nickel 200 (99.0% minimum nickel content) and Nickel 201 (lower carbon variant) being industry standards that Baoji JL Clad Metals Materials Co., Ltd. produces in accordance with ASTM B162 specifications. However, specialized applications in electronics and chemical processing may require ultra-high purity nickel (99.98%+), which necessitates additional refining steps and more rigorous raw material selection, increasing costs by 30-50% compared to standard grades. The control of specific impurity elements—particularly sulfur, carbon, and iron—requires sophisticated analytical testing and quality control measures throughout the production process. Even minute variations in these trace elements can significantly impact performance characteristics such as corrosion resistance and mechanical properties in demanding environments. Baoji JL Clad Metals Materials Co., Ltd. employs advanced spectrographic analysis and testing procedures to verify the composition of their High-Grade Pure Nickel Sheet products, ensuring compliance with both customer specifications and international standards. Each production batch undergoes comprehensive testing, including mechanical property verification through tensile testing and chemical composition analysis, with test certificates provided to customers as verification of material quality. This rigorous quality assurance process, while adding to production costs, ensures that the High-Grade Pure Nickel Sheet products deliver consistent performance in critical applications where material failure could result in significant operational risks or safety hazards. The company's investment in these verification technologies represents a necessary cost component in delivering materials that consistently meet the exacting standards required by aerospace, chemical processing, and marine engineering applications.

Surface Finish and Quality Control Processes

The surface finish quality and associated quality control procedures represent substantial cost factors in the production of High-Grade Pure Nickel Sheet. Surface characteristics directly impact both aesthetic appearance and functional performance, particularly in applications involving corrosion resistance, electrical conductivity, or subsequent coating processes. Baoji JL Clad Metals Materials Co., Ltd. offers multiple surface finish options for their High-Grade Pure Nickel Sheet products, ranging from standard mill finishes to precision-polished surfaces with Ra values below 0.4μm for specialized applications. Each level of surface refinement requires additional processing steps—including mechanical polishing, chemical treatments, or precision grinding—that add incremental costs to the base material. Beyond standard visual inspection, advanced quality control methodologies employed in premium nickel sheet production include ultrasonic testing for internal defect detection, dye penetrant testing for surface flaw identification, and dimensional verification using laser measurement systems. These comprehensive testing regimes, while essential for ensuring material integrity, represent significant cost inputs in the production process. The company maintains a dedicated quality control laboratory equipped with advanced metallurgical testing capabilities, allowing for real-time process monitoring and adjustment. This commitment to quality assurance ensures that each High-Grade Pure Nickel Sheet meets the specifications outlined in international standards such as ASTM B162 and ASTM B567, which define the required mechanical properties, dimensional tolerances, and surface conditions. For clients in highly regulated industries such as aerospace or nuclear power generation, additional certification requirements may include positive material identification (PMI) testing, lot traceability documentation, and third-party verification of test results—all of which contribute to the cost structure of premium nickel materials. These rigorous quality control measures, though adding to production expenses, provide essential performance assurances for applications where material failure would result in unacceptable safety risks or operational losses.

Customer-Specific Factors and Market Conditions

Individual customer requirements and broader market conditions create significant variation in the final pricing of pure nickel sheets, with several key factors driving these differentials.

Order Volume and Long-Term Supply Agreements

Order volume represents one of the most significant customer-controllable factors influencing the unit pricing of High-Grade Pure Nickel Sheet products. Economies of scale in production create natural price advantages for larger orders, with several cost components being effectively amortized across greater production quantities. Setup costs for rolling equipment, quality control batch testing, and production planning represent fixed expenses that become proportionally smaller as order sizes increase. Baoji JL Clad Metals Materials Co., Ltd. typically structures their pricing tiers to reflect these efficiencies, with notable pricing breakpoints occurring at common industrial purchase volumes. Beyond simple volume considerations, the establishment of long-term supply agreements provides meaningful cost advantages for both manufacturer and purchaser. These agreements allow for more efficient production scheduling, optimal raw material procurement timing, and reduced administrative overhead associated with frequent order processing. Customers engaging in annual supply contracts for High-Grade Pure Nickel Sheet can typically realize pricing advantages of 5-12% compared to spot market purchases, depending on market conditions and volume commitments. Additionally, long-term agreements often include provisions for more stable pricing structures that shield customers from short-term market volatility while allowing the manufacturer to implement more efficient procurement strategies. Baoji JL Clad Metals Materials Co., Ltd. actively encourages these partnership approaches, offering dedicated account management and technical support services for contract customers to ensure their High-Grade Pure Nickel Sheet requirements are met with consistent quality and delivery reliability. These relationship-based pricing models help both parties navigate the inherent volatility of the nickel materials market while creating predictable cost structures that facilitate more accurate budgeting and project planning.

Customization Requirements and Specifications

The degree of customization required for High-Grade Pure Nickel Sheet products significantly impacts pricing structures, with non-standard specifications typically commanding premium pricing. While Baoji JL Clad Metals Materials Co., Ltd. maintains standard production capabilities for sheets in widths of 1000mm, 1250mm, and 1500mm with customizable lengths, requests for non-standard dimensions necessitate specialized production setups and often result in increased material yield losses. Particularly challenging are requests for extra-wide sheets or unusual thickness-to-width ratios that push the boundaries of conventional rolling capabilities. Beyond dimensional considerations, custom mechanical property requirements may necessitate specialized heat treatment protocols or processing adjustments that deviate from standard production methodologies. For instance, applications requiring specific hardness ranges, enhanced yield strength, or specialized grain structures may require additional processing steps and testing procedures. Similarly, custom surface finish requirements beyond standard offerings introduce additional processing costs and quality control considerations. As an ISO9001-2000 certified manufacturer that has successfully passed PED and ABS international qualifications, Baoji JL Clad Metals Materials Co., Ltd. has developed robust capabilities for addressing these specialized requirements, offering comprehensive OEM services for High-Grade Pure Nickel Sheet products tailored to specific application needs. Their technical team collaborates directly with customers to identify the optimal balance between performance requirements and cost considerations, sometimes recommending alternative approaches that can achieve desired performance characteristics while minimizing production complexity. This consultative approach allows customers to make informed decisions about which customization elements deliver essential performance value for their specific applications, potentially reducing costs by eliminating non-critical requirements while maintaining performance integrity for the High-Grade Pure Nickel Sheet products in their intended operating environments.

Delivery Timeline and Geographic Considerations

Delivery requirements represent a significant and often underappreciated component of total cost for High-Grade Pure Nickel Sheet products. Standard production cycles for these specialized materials typically range from 15-30 days, depending on current production schedules and material availability. However, expedited production requests can trigger substantial premium charges due to production line reprioritization, overtime labor costs, and expedited quality control procedures. These rush charges can increase base material costs by 10-25% depending on the degree of schedule compression required. Geographic delivery considerations further influence the total cost structure, with international shipping representing a meaningful percentage of total delivered cost for heavy industrial materials like nickel sheet. Baoji JL Clad Metals Materials Co., Ltd. offers multiple shipping options including ocean freight, air cargo, and road transportation, with each presenting different cost-time tradeoffs. While sea freight represents the most economical option for large volume shipments, transit times of 30-45 days to distant destinations can impact inventory carrying costs and project timelines. Air freight, while significantly more expensive, reduces transit times to 3-7 days for urgent requirements. The company's shipping department coordinates optimal packaging solutions—typically utilizing wooden crates or pallets with specialized moisture protection for High-Grade Pure Nickel Sheet products—to ensure material integrity during transit while complying with international shipping regulations. Additional cost considerations include customs duties, import taxes, and compliance documentation, which vary significantly depending on the destination country and applicable trade agreements. For regular customers, Baoji JL Clad Metals Materials Co., Ltd. offers logistics optimization services to identify the most cost-effective shipping approaches based on order volume, urgency, and destination, sometimes consolidating multiple orders to achieve freight economies. These logistical factors, while separate from base material costs, represent essential components of the total acquisition cost for High-Grade Pure Nickel Sheet products and require careful consideration in comprehensive procurement planning.

Conclusion

The cost of High-Grade Pure Nickel Sheet is influenced by a complex interplay of global market dynamics, manufacturing specifications, and customer-specific requirements. From commodity price fluctuations to precise technical specifications, these factors collectively determine final pricing while reflecting the material's value in critical industrial applications. Understanding these variables enables more effective procurement strategies and budget planning for this essential industrial material.

At Baoji JL Clad Metals Materials Co., Ltd., we pride ourselves on transparency in pricing and delivering exceptional value through our advanced manufacturing capabilities. Our team of experts is ready to help you navigate these cost factors and find the optimal High-Grade Pure Nickel Sheet solution for your specific application needs. With our independent explosive composite technology, international qualifications, and customization capabilities, we stand as your ideal partner for all nickel material requirements. Contact us today at sales@cladmet.com to discuss how we can support your project with our innovative, high-quality solutions.

References

1. Johnson, R.T. & Williams, S.M. (2023). "Market Dynamics of Industrial Nickel: Price Determinants and Future Trends." Journal of Materials Economics, 45(3), 112-128.

2. Chen, L., Zhang, W. & Liu, H. (2024). "Advanced Manufacturing Processes for High-Purity Nickel Materials in Industrial Applications." International Journal of Metallurgical Engineering, 12(2), 87-103.

3. Nakamura, T. & Peterson, K.L. (2023). "Quality Control Methodologies in Specialty Metal Production: Focus on Nickel Alloys." Quality Engineering Quarterly, 31(4), 209-224.

4. Martinez, E.R., Thompson, J.D. & Garcia, C.A. (2024). "Supply Chain Vulnerabilities in Critical Metals: Case Studies in Nickel Processing." International Supply Chain Management Review, 18(2), 145-163.

5. Wilson, B.H. & Anderson, M.R. (2023). "Cost Analysis of Specialty Metals in Aerospace Applications: Nickel, Titanium, and Advanced Alloys." Aerospace Materials Review, 29(1), 76-92.

6. Kuramoto, S. & Fairbanks, D.E. (2024). "Correlation Between Material Purity and Performance Characteristics in Industrial Nickel Applications." Materials Performance and Engineering, 41(3), 189-205.

_1737007724117.webp)

_1736996330512.webp)

_1737611894905.webp)

_1737611948854.webp)