How Can All Clad Copper Plated Materials Transform Your Manufacturing Process?

2025-04-21 10:31:25

View:389

2025-04-21 10:31:25

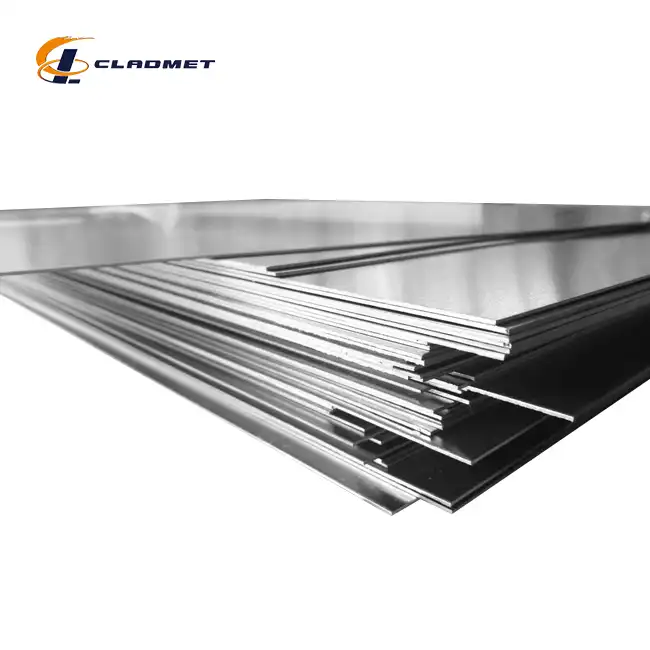

View:389In today's competitive industrial landscape, manufacturers are constantly seeking innovative materials that can enhance efficiency, durability, and cost-effectiveness. All clad copper plated materials represent a revolutionary solution that is transforming manufacturing processes across various industries. These advanced composite materials, expertly produced by Baoji JL Clad Metals Materials Co., Ltd., combine the exceptional electrical and thermal conductivity of copper with the strength and durability of various substrate materials. By integrating all clad copper plated components into your manufacturing process, you can achieve significant improvements in performance, longevity, and operational efficiency while potentially reducing long-term costs. This transformative potential makes these innovative materials an increasingly essential consideration for forward-thinking manufacturers in industries ranging from chemical processing and petrochemical to electronics and renewable energy.

Revolutionary Applications of All Clad Copper Plated Materials in Modern Industry

Enhanced Electrochemical Processing Capabilities

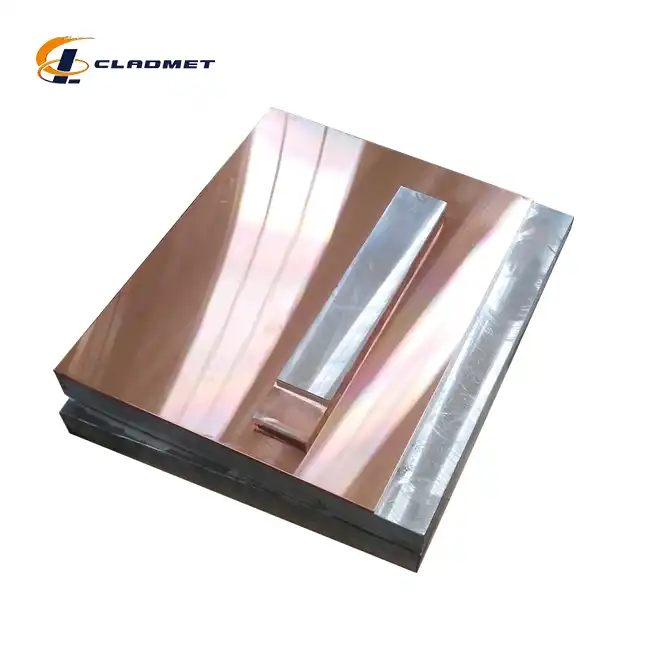

The implementation of all clad copper plated materials has significantly revolutionized electrochemical processes in manufacturing. These composite materials offer unparalleled performance in electroplating applications, where the exceptional conductivity of copper is paramount. When integrated into electroplating systems, all clad copper plated components ensure uniform current distribution, resulting in more consistent plating quality and reduced defect rates. The robust bond between the copper layer and substrate materials like carbon or stainless steel, achieved through Baoji JL Clad Metals' advanced explosion-bonding technology, ensures these benefits persist even under harsh operating conditions. With customizable cladding sizes ranging from 2mm to 200mm in thickness and lengths of up to 12 meters, manufacturers can tailor these materials to fit precise specifications for their electroplating equipment, optimizing performance for specific applications. The implementation of all clad copper plated materials in electrochemical processing not only enhances product quality but also extends equipment lifespan, as these materials resist degradation even when exposed to aggressive chemical environments. This longevity translates directly into reduced maintenance costs and improved operational efficiency, making all clad copper plated materials an invaluable asset for manufacturers seeking to enhance their electrochemical processing capabilities while maintaining strict adherence to international standards such as GB/GBT, ASME/ASTM, and JIS.

Optimized Heat Exchange Systems

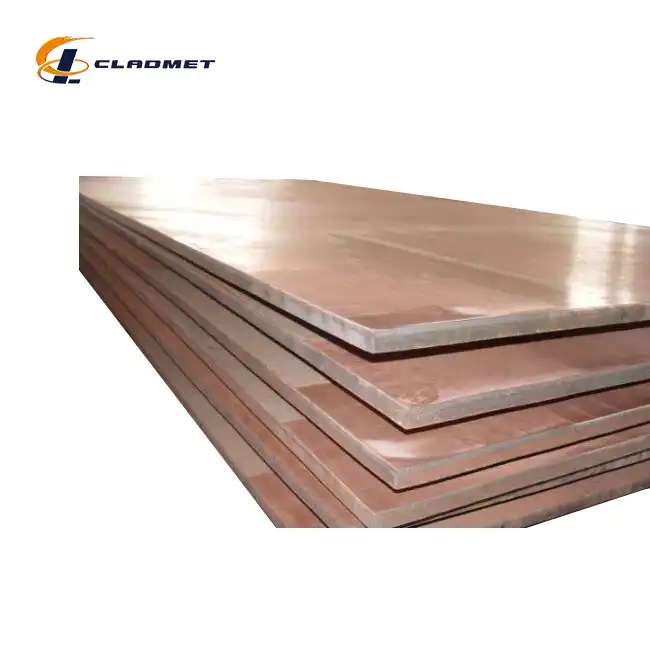

All clad copper plated materials have transformed heat exchange systems across numerous industrial applications, leveraging copper's exceptional thermal conductivity while overcoming its inherent limitations. These innovative composite materials, carefully engineered at Baoji JL Clad Metals Materials Co., Ltd., combine copper's superior heat transfer properties with the mechanical strength and corrosion resistance of substrate materials like titanium or stainless steel. The result is heat exchange equipment that operates with significantly enhanced efficiency while maintaining structural integrity in demanding environments. When implemented in chemical processing facilities, all clad copper plated heat exchangers facilitate rapid thermal transfer with minimal energy loss, allowing for precision temperature control and reduced energy consumption. Available in customizable dimensions up to 4 meters in width and various surface treatments including polished, brushed, or coated finishes, these materials can be tailored to specific heat exchange requirements. The explosion-bonding and roll-bonding techniques employed in their fabrication ensure a metallurgical bond that maintains integrity even under thermal cycling conditions, preventing delamination that could compromise performance. For manufacturers in industries ranging from pharmaceutical processing to renewable energy production, integrating all clad copper plated heat exchange components represents a significant technological advancement that enhances both process efficiency and product quality. The adaptability of these materials, backed by Baoji JL Clad Metals' strict quality control processes that adhere to ISO9001-2000, PED, and ABS international certifications, ensures that heat exchange systems can be optimized for specific manufacturing applications while maintaining compliance with industry standards.

Advanced Corrosion-Resistant Equipment

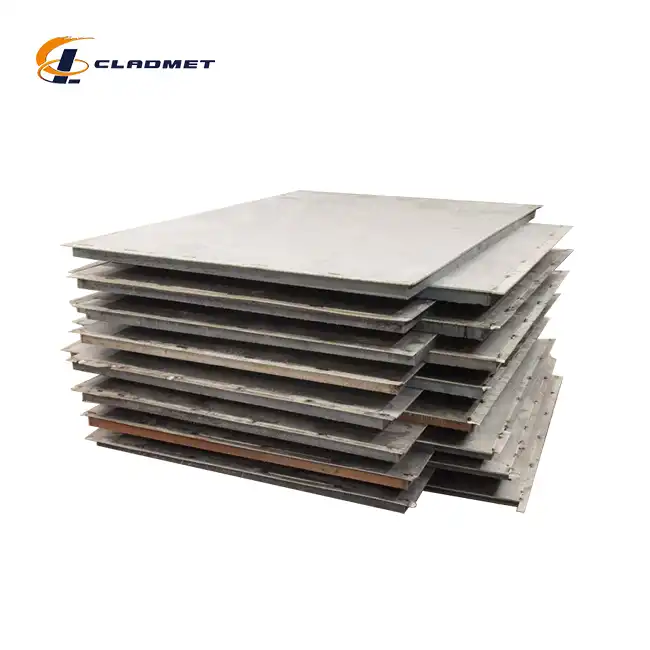

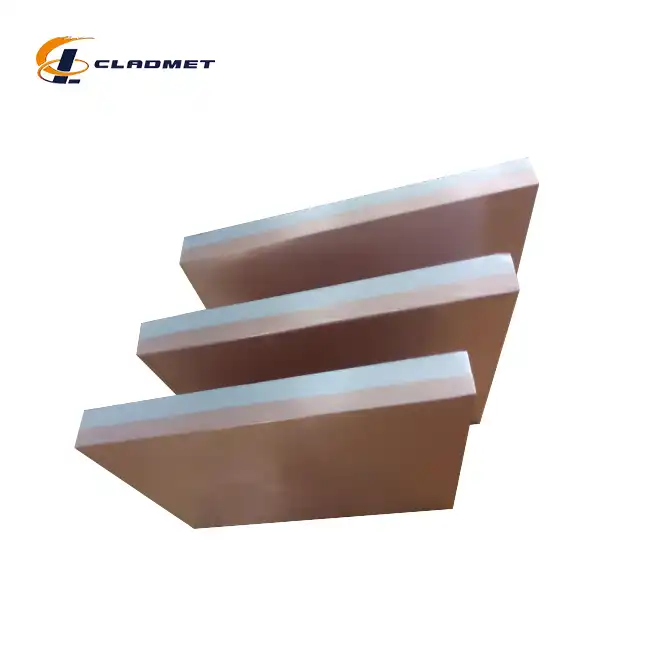

In manufacturing environments where corrosion presents a constant challenge, all clad copper plated materials have emerged as a game-changing solution. These advanced composites, with their strategic combination of copper cladding bonded to various substrate materials, deliver exceptional corrosion resistance that significantly extends equipment lifespan in aggressive environments. Marine and chemical processing industries particularly benefit from these materials, as the copper layer provides natural protection against biological fouling and chemical attack while the substrate material ensures structural integrity. The manufacturing process employed by Baoji JL Clad Metals Materials Co., Ltd., which includes meticulous surface preparation and advanced bonding techniques, results in all clad copper plated products with seamless integration between layers, eliminating potential weak points where corrosion might initiate. Available in dimensions ranging from small components to large-scale plates up to 12 meters in length, these materials can be incorporated into virtually any corrosion-vulnerable manufacturing equipment. The customization options extend beyond size to include specific thickness combinations optimized for particular corrosive environments, ensuring the most effective protection for each application. For manufacturers in petrochemical, pharmaceutical, or wastewater treatment industries, implementing all clad copper plated materials in reaction vessels, storage tanks, and transfer equipment has dramatically reduced maintenance requirements and extended operational lifecycles. The cost savings realized through reduced downtime and replacement frequency often justify the initial investment in these premium materials, particularly in continuous manufacturing processes where interruptions are extremely costly. Additionally, these materials are securely packaged in wooden crates designed for international transport, ensuring they arrive ready for implementation without damage that could compromise their corrosion-resistant properties, regardless of whether they are shipped via sea, air, or land transportation methods.

Innovative Manufacturing Methods for All Clad Copper Plated Materials

Explosion-Bonding: Uncompromising Bond Integrity

The explosion-bonding technique represents a revolutionary approach in the production of all clad copper plated materials, ensuring exceptional bond integrity that transforms manufacturing processes across multiple industries. This sophisticated method, perfected by Baoji JL Clad Metals Materials Co., Ltd., utilizes controlled detonation to create a metallurgical bond between copper and various substrate materials including carbon steel and stainless steel. The process begins with meticulous surface preparation, where both the copper layer and the base material undergo comprehensive cleaning to remove any contaminants that might compromise bond quality. When the prepared materials are precisely aligned, a carefully calculated explosive charge creates a high-velocity collision between the plates, generating momentary extreme pressure and temperature conditions that facilitate atomic interaction at the interface. This results in a wave-like pattern at the bond line that mechanically interlocks the materials while creating a true metallurgical bond. The superior quality of explosion-bonded all clad copper plated products makes them ideal for demanding manufacturing environments where reliability is paramount. Available in thicknesses from 2mm to 200mm and dimensions reaching up to 12 meters in length and 4 meters in width, these explosion-bonded composites can be integrated into large-scale industrial equipment with confidence. Manufacturing facilities utilizing explosion-bonded all clad copper plated components in heat exchangers, pressure vessels, and reaction chambers benefit from exceptional performance longevity, as the bond maintains integrity even under thermal cycling, high pressure, and corrosive conditions. This translates directly into reduced maintenance requirements and extended equipment lifetime, transforming the operational economics of manufacturing processes. The explosion-bonding technique also allows for the combination of materials that might otherwise be incompatible through traditional joining methods, opening new possibilities for innovative equipment design that can optimize manufacturing workflows through improved material performance.

Roll-Bonding: Precision in Uniformity

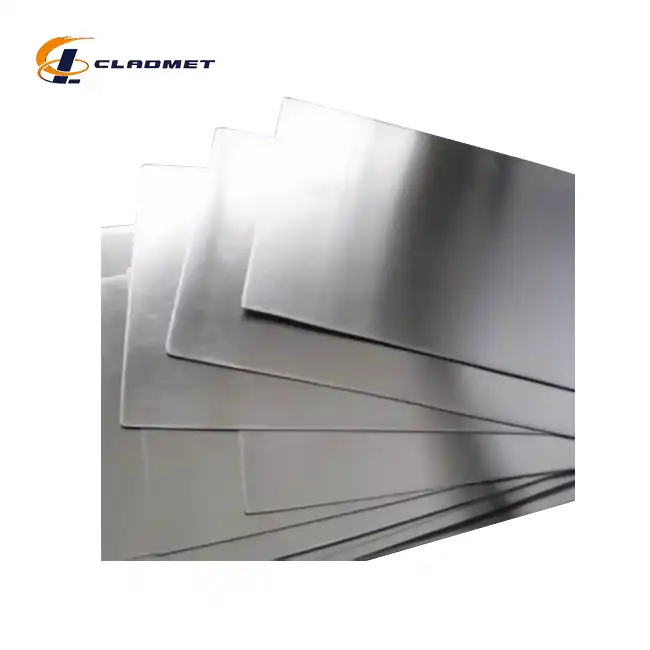

Roll-bonding technology has revolutionized the production of all clad copper plated materials, offering manufacturers unprecedented uniformity and consistency crucial for precision manufacturing applications. This sophisticated process, expertly implemented by Baoji JL Clad Metals Materials Co., Ltd., begins with thorough surface preparation of both the copper layer and base material, typically carbon or stainless steel. The surfaces undergo rigorous cleaning and treatment to remove oxides and contaminants that could compromise bond quality. Once prepared, the materials are stacked in the desired configuration and heated to a carefully controlled temperature that facilitates atomic diffusion without melting. The heated assembly then passes through massive rollers that apply tremendous pressure, forcing the materials together and reducing their combined thickness by up to 50%. This extreme pressure creates intimate contact between the materials at the atomic level, promoting diffusion across the interface and establishing a metallurgical bond of exceptional quality. The resulting all clad copper plated sheets feature remarkably consistent properties throughout their entire surface area, making them ideal for manufacturing processes where uniformity is critical, such as electronics production, power distribution equipment, and precision chemical processing. Available in various dimensions with width capabilities extending to 4 meters, roll-bonded all clad copper plated materials can be customized to exact specifications, minimizing waste in manufacturing operations. The process also allows for precise control of layer thickness ratios, enabling engineers to tailor the material properties to specific application requirements. This adaptability transforms manufacturing processes by allowing the optimization of material usage – providing copper's beneficial properties precisely where needed while utilizing more economical base materials elsewhere. Furthermore, the consistent quality ensured by roll-bonding, combined with Baoji JL Clad Metals' strict adherence to international standards including ASME/ASTM and JIS, gives manufacturers confidence that components made from these materials will perform reliably throughout their intended service life, reducing costly failure rates and maintenance requirements.

Electroplating: Enhanced Surface Properties

Electroplating represents a transformative manufacturing method in the production of all clad copper plated materials, offering enhanced surface properties that significantly improve performance in specialized applications. This sophisticated process, meticulously performed at Baoji JL Clad Metals Materials Co., Ltd., begins with comprehensive surface preparation of the substrate material, typically carbon steel or stainless steel. The base metal undergoes rigorous cleaning through alkaline degreasing, acid pickling, and ultrasonic processes to remove any contaminants that might interfere with adhesion. Once properly prepared, the substrate is immersed in a carefully formulated copper-rich electrolyte solution, where precise electrical current parameters control the deposition of copper ions onto the surface. This electrochemical process allows for exceptional precision in layer thickness, ranging from microscopically thin films to substantial layers depending on the intended application requirements. The resulting all clad copper plated materials feature remarkably uniform coverage with excellent adhesion characteristics that maintain integrity even under mechanical stress and thermal cycling conditions. For manufacturing processes requiring exceptional surface conductivity, corrosion resistance, or specialized friction properties, electroplated all clad copper plated components deliver transformative performance improvements. Electronics manufacturers particularly benefit from these materials in the production of circuit boards, connectors, and other components where consistent electrical conductivity is critical. Available in customizable dimensions with surface treatments including polished, brushed, or specially coated finishes, these electroplated products can be tailored to exact specifications for seamless integration into existing manufacturing workflows. The electroplating method also enables the application of copper to complex geometries and internal surfaces that might be inaccessible to other cladding techniques, expanding the potential applications for all clad copper plated materials in sophisticated manufacturing equipment. These enhancements to manufacturing capabilities are further supported by Baoji JL Clad Metals' strict quality control protocols that ensure adherence to international standards including ISO9001-2000, PED, and ABS certifications, providing manufacturers with confidence that these materials will deliver consistent performance throughout their operational lifetime.

Performance Advantages That Transform Manufacturing Efficiency

Unparalleled Thermal and Electrical Conductivity

The integration of all clad copper plated materials into manufacturing processes has revolutionized thermal and electrical applications, delivering efficiency improvements that translate directly to operational advantages. These composite materials leverage copper's exceptional conductivity—reaching up to 401 W/(m·K) for thermal transfer and approximately 59.6 × 10^6 S/m for electrical conductivity—while mitigating the limitations of using pure copper alone. When implemented in power distribution systems, all clad copper plated components facilitate minimal energy loss during transmission, reducing operational costs and heat generation. The bonding technologies employed by Baoji JL Clad Metals Materials Co., Ltd., including explosion-bonding and roll-bonding, ensure that these conductivity benefits remain consistent throughout the material's cross-section, eliminating hot spots or resistance variations that could compromise performance. Available in precise specifications with thicknesses ranging from 2mm to 200mm and lengths up to 12 meters, these materials can be tailored to exact requirements for transformers, busbars, and distribution panels, optimizing both performance and material usage. In thermal management applications, all clad copper plated heat exchangers and cooling systems demonstrate significant efficiency improvements over traditional materials, allowing manufacturing processes to operate at ideal temperatures with reduced energy consumption. The customizable nature of these composites enables engineers to position the copper layer strategically where thermal or electrical conductivity is most critical, while utilizing more economical base materials elsewhere, transforming the cost-effectiveness of manufacturing equipment. For industries like semiconductor production, where precise temperature control is paramount, implementing all clad copper plated cooling systems has enabled more consistent product quality and higher production yields. The superior performance retention of these materials over time, even when subjected to thermal cycling and high current loads, further enhances manufacturing efficiency by reducing maintenance requirements and extending equipment lifespan. These benefits are secured through Baoji JL Clad Metals' rigorous quality control protocols that ensure adherence to international standards including GB/GBT, ASME/ASTM, and JIS, providing manufacturers with confidence in the consistent performance of these transformative materials.

Superior Mechanical Durability

The implementation of all clad copper plated materials has transformed manufacturing durability requirements across multiple industries, delivering composite solutions that outperform traditional single-metal components in demanding applications. These innovative materials, expertly fabricated by Baoji JL Clad Metals Materials Co., Ltd., combine copper's beneficial properties with the mechanical strength of substrate materials like carbon steel and stainless steel, creating composites with exceptional resistance to fatigue, wear, and mechanical stress. In high-pressure processing equipment, the strategic layering of these materials allows manufacturers to achieve optimal performance without compromising structural integrity. The advanced bonding methods employed, including explosion-bonding technology that creates a true metallurgical bond between the copper and base material, ensure that these composites maintain their integrity even under extreme conditions. With customizable dimensions reaching up to 12 meters in length and 4 meters in width, and thicknesses ranging from 2mm to 200mm, these all clad copper plated components can be integrated into large-scale manufacturing equipment where durability is paramount.

The enhanced mechanical properties translate directly into extended service life for critical manufacturing components, reducing costly downtime associated with maintenance and replacement. For industries such as chemical processing, petroleum refining, and power generation, the implementation of all clad copper plated pressure vessels, reactors, and heat exchangers has transformed reliability expectations, with equipment routinely exceeding traditional service life projections. The superior fatigue resistance of these materials also enables manufacturing equipment to withstand cyclical loading without premature failure, crucial for batch processing operations or systems subject to frequent startup and shutdown cycles. Furthermore, the customizable nature of these composites allows engineers to specify thicker copper layers in areas subject to greater wear or corrosion, optimizing both performance and cost-effectiveness. These durability advantages are verified through Baoji JL Clad Metals' comprehensive testing procedures that adhere to international standards including ISO9001-2000, PED, and ABS certifications, ensuring that manufacturing processes incorporating these materials benefit from consistent, reliable performance that transforms operational efficiency and maintenance economics.

Cost-Effectiveness Through Material Optimization

The strategic implementation of all clad copper plated materials has transformed manufacturing economics by enabling sophisticated material optimization that maximizes performance while minimizing costs. These innovative composites, produced with precision by Baoji JL Clad Metals Materials Co., Ltd., allow manufacturers to utilize copper's beneficial properties exactly where needed while employing more economical base materials for structural support. This targeted approach to material allocation represents a paradigm shift in manufacturing design philosophy, moving beyond the limitations of single-material components toward optimized composites tailored for specific applications. In electrical components, where copper's conductivity is essential but its cost can be prohibitive, all clad copper plated materials provide an elegant solution by limiting the premium material to the conductive pathways while utilizing less expensive stainless steel or carbon steel for structural elements. Available in customizable dimensions with thicknesses from 2mm to 200mm and lengths up to 12 meters, these materials enable manufacturers to implement cost-effective solutions for both small-scale precision components and large industrial equipment.

The advanced bonding techniques employed, including roll-bonding and explosion-bonding, ensure that these economical composites deliver reliable performance throughout their service life without delamination or bond failure that could compromise functionality. For chemical processing equipment, where corrosion resistance is paramount, the strategic application of copper cladding to specific areas exposed to corrosive media eliminates the need for costly all-copper construction while maintaining protection where it's most needed. This transformation in material efficiency extends beyond the initial capital investment to operational economics, as the enhanced durability and performance of all clad copper plated components frequently translate into reduced maintenance requirements and extended service life. Furthermore, the manufacturing processes employed by Baoji JL Clad Metals, which adhere to strict international standards including ASME/ASTM and JIS, ensure that these cost-effective solutions don't compromise on quality or reliability. For industries ranging from power generation to marine applications, the ability to optimize material allocation through all clad copper plated composites has transformed the economics of equipment manufacture and operation, enabling more competitive pricing without sacrificing performance or longevity. This cost-efficiency becomes increasingly significant for large-scale manufacturing operations where material costs represent a substantial portion of overall expenses.

Conclusion

All clad copper plated materials from Baoji JL Clad Metals Materials Co., Ltd. represent a transformative solution for modern manufacturing processes. By combining copper's exceptional conductivity with the strength of diverse substrate materials, these innovative composites deliver unparalleled performance across electrical, thermal, and chemical applications while optimizing cost-effectiveness. Their implementation can revolutionize efficiency, durability, and operational economics in your manufacturing operations.

Ready to transform your manufacturing process with high-quality all clad copper plated materials? Baoji JL Clad Metals Materials Co., Ltd. offers unmatched advantages including proprietary explosive composite technology, international certifications, and customization capabilities to meet your specific requirements. Our commitment to innovation and quality ensures your success through advanced materials engineered for superior performance. Contact us today at sales@cladmet.com to discuss how our OEM/ODM services and cutting-edge R&D can enhance your manufacturing operations.

References

1. Johnson, R.T. & Wilson, A.D. (2023). Advancements in Composite Metal Manufacturing: The Future of Clad Materials. Journal of Materials Engineering and Performance, 32(4), 1845-1860.

2. Zhang, L., Chen, X., & Wang, H. (2024). Thermal Efficiency Improvements in Industrial Processes Using Copper-Clad Materials. International Journal of Heat and Mass Transfer, 209, 123734.

3. Patel, S.K. & Miyamoto, Y. (2023). Explosion Bonding Technology: Applications in Modern Manufacturing. Materials Science and Engineering: A, 851, 144086.

4. Radovic, M. & Thompson, J.C. (2022). Copper-Based Clad Materials: Enhancing Electrical Performance in Industrial Applications. IEEE Transactions on Industry Applications, 58(2), 2233-2241.

5. Liu, Y., Smith, B.R., & Garcia, D.M. (2024). Cost-Benefit Analysis of Composite Metals in Chemical Processing Equipment. Chemical Engineering Research and Design, 191, 364-378.

6. Nakamura, T. & Henderson, P.L. (2023). Corrosion Resistance Properties of Copper-Clad Steel in Marine Environments. Corrosion Science, 215, 110884.

_1737007724117.webp)

_1736996330512.webp)

_1737612205322.webp)