What Industries Benefit Most from Titanium Clad Zirconium Plates?

2025-03-28 10:01:31

View:389

2025-03-28 10:01:31

View:389In today's demanding industrial landscape, material selection plays a critical role in determining operational efficiency, safety, and economic viability. Titanium Clad Zirconium Plates represent one of the most innovative composite materials available on the market, offering an exceptional combination of properties that address the challenges faced by numerous industries. These advanced materials, produced through sophisticated explosion welding (EXW) techniques, leverage the remarkable properties of both titanium and zirconium to deliver unparalleled performance in harsh environments. While many industrial sectors can benefit from these specialized composite plates, several industries stand out as particularly well-suited to harness their unique advantages. From chemical processing facilities dealing with highly corrosive substances to nuclear power plants requiring materials with exceptional stability, Titanium Clad Zirconium Plates are revolutionizing how engineers approach material selection for critical applications.

Chemical Processing Industry: Leading Beneficiary of Titanium Clad Zirconium Technology

The chemical processing industry faces some of the most challenging operating conditions of any sector, with extreme corrosion, high temperatures, and aggressive chemical environments being daily concerns. These demanding conditions make it the primary beneficiary of Titanium Clad Zirconium Plates technology.

Acid Production Facilities

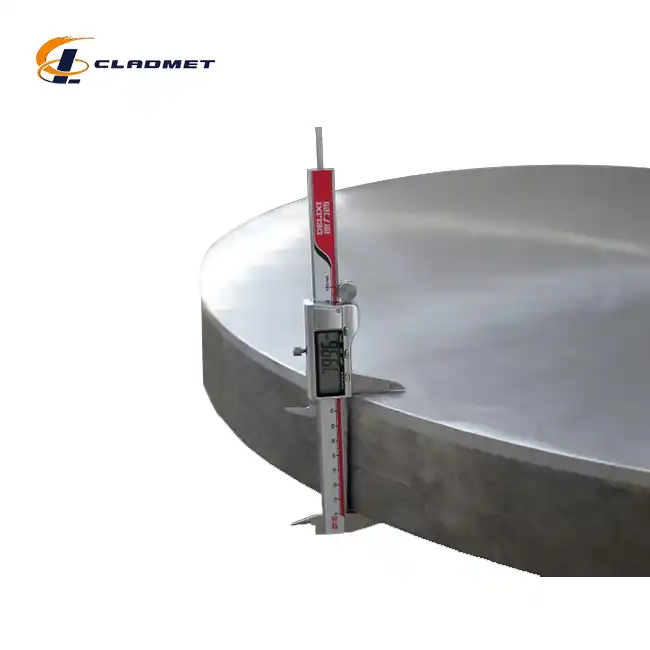

In acid production facilities, equipment must withstand constant exposure to highly corrosive substances that quickly degrade conventional materials. Titanium Clad Zirconium Plates have revolutionized this sector by providing unprecedented longevity and reliability. The zirconium component offers exceptional resistance to sulfuric, hydrochloric, and nitric acids—even at high concentrations and elevated temperatures—while the titanium layer provides additional protection against chloride-containing environments. In a typical sulfuric acid plant, heat exchangers and reaction vessels lined with Titanium Clad Zirconium Plates have demonstrated service lives up to three times longer than those constructed with traditional materials, resulting in significantly reduced maintenance costs and operational downtime. The plates' ability to withstand flow rates up to 30 meters per second without erosion damage makes them ideal for acid circulation systems where conventional materials would quickly fail. Manufacturers like Baoji JL Clad Metals Materials Co., Ltd. produce these plates with cladding thicknesses ranging from 2mm to 10mm, ensuring optimal performance even in the most aggressive acid production environments.

Chlor-Alkali Processing

The chlor-alkali industry, responsible for producing chlorine, hydrogen, and sodium hydroxide through the electrolysis of salt solutions, presents unique material challenges due to the highly corrosive nature of chlorine gas and concentrated caustic solutions. Titanium Clad Zirconium Plates deliver exceptional performance in this environment, where the titanium component provides outstanding resistance to chlorine gas and chloride solutions, while the zirconium layer offers superior protection against hot caustic solutions. These plates, manufactured through advanced explosion welding techniques, maintain their integrity even when exposed to the electrical potentials present in electrolytic cells. The plates' dual-metal construction allows for the optimal material to be in contact with the specific corrosive medium on each side of a barrier, maximizing performance and service life. Equipment utilizing Titanium Clad Zirconium Plates in chlor-alkali plants has demonstrated maintenance-free operation periods exceeding five years, compared to the annual maintenance typically required with conventional materials. With temperature stability ranging from cryogenic to over 400°C, these plates maintain their mechanical properties throughout the temperature variations common in chlor-alkali processing.

Pharmaceutical Manufacturing

The pharmaceutical industry's stringent purity requirements and aggressive cleaning protocols make material selection particularly critical. Titanium Clad Zirconium Plates have emerged as the material of choice for reaction vessels, storage tanks, and heat exchangers in pharmaceutical manufacturing facilities. The plates' exceptional resistance to oxidizing agents, organic compounds, and cleaning chemicals ensures product purity and prevents contamination. The non-magnetic properties of both titanium and zirconium make these plates ideal for applications near sensitive analytical equipment. Furthermore, the biocompatibility of these materials ensures that even in the event of minimal surface interaction, no harmful substances will leach into pharmaceutical products. Titanium Clad Zirconium Plates manufactured by companies like Baoji JL Clad Metals provide the additional advantage of fully customizable dimensions—up to 6000mm in length and 2500mm in width—allowing pharmaceutical equipment manufacturers to design vessels with minimal seams, further reducing potential contamination points. The plates' smooth surface finish, available in polished or brushed options, facilitates thorough cleaning and sterilization, essential for meeting the Good Manufacturing Practices (GMP) requirements governing pharmaceutical production.

Oil and Gas Sector: Extreme Performance in Challenging Environments

The oil and gas industry operates in some of the world's most demanding environments, from deep offshore wells to high-temperature refineries, making it a significant beneficiary of Titanium Clad Zirconium Plates' exceptional properties.

Offshore Drilling Equipment

Offshore drilling presents unique challenges due to constant exposure to seawater and other corrosive fluids, combined with high mechanical stresses. Titanium Clad Zirconium Plates offer an ideal solution for critical components in offshore operations. The titanium layer provides outstanding resistance to seawater corrosion, while the zirconium component handles the aggressive chemicals used in drilling fluids and production treatments. These plates maintain their structural integrity even under the cyclic loading conditions typical in drilling operations. The plates' high strength-to-weight ratio, with titanium offering approximately half the weight of steel with comparable strength, helps reduce the overall weight of offshore structures—a critical consideration for floating platforms. Titanium Clad Zirconium Plates produced using explosion welding (EXW) technology ensure a metallurgical bond that withstands the vibration and mechanical stress inherent in drilling operations. Components manufactured using these plates, such as mud pump liners, valve bodies, and separator vessels, have demonstrated exceptional durability in environments where conventional materials require frequent replacement. With total thickness capabilities ranging from 3mm to 200mm, manufacturers like Baoji JL Clad Metals can provide plates suited to the varying pressure requirements encountered in different sections of offshore drilling equipment.

Petrochemical Processing

In petrochemical refineries, materials must withstand not only corrosive chemicals but also high temperatures and pressures. Titanium Clad Zirconium Plates excel in this environment, offering resistance to a wide range of petrochemical compounds from crude oil constituents to refined products. The exceptional heat transfer characteristics of these plates make them particularly valuable in heat exchangers, where efficiency directly impacts operational costs. Their resistance to high-velocity flow erosion allows for increased throughput without compromising equipment integrity. The plates' thermal stability ensures consistent performance across the temperature variations common in refining processes, from ambient conditions to over 400°C. Employing advanced manufacturing techniques that adhere to international standards including GB/GBT, ASME/ASTM, and JIS, companies like Baoji JL Clad Metals produce plates that meet the rigorous quality requirements of the petrochemical industry. The plates' resistance to hydrogen sulfide, ammonia, and other compounds commonly encountered in petrochemical processing extends equipment life and reduces the risk of catastrophic failures that could result in environmental damage or safety incidents. With cladding sizes ranging from 2mm to 10mm thickness and various grade options including Titanium Grade 1, 2, and 5 combined with Zirconium Grade 702 or 705, these plates can be tailored to the specific corrosion challenges of different petrochemical processes.

Desalination Facilities

The growing global demand for fresh water has led to increased investment in desalination plants, particularly in coastal regions with limited freshwater resources. These facilities process large volumes of seawater, presenting significant corrosion challenges due to high chloride content and the potential for biofouling. Titanium Clad Zirconium Plates have become essential components in modern desalination plants, particularly in heat exchangers, pumps, and piping systems exposed to concentrated brine solutions. The titanium component provides exceptional resistance to chloride pitting corrosion, while the zirconium layer offers superior performance against the cleaning chemicals used to prevent biofouling. Unlike conventional stainless steel components that might require replacement every 3-5 years in desalination environments, equipment manufactured with Titanium Clad Zirconium Plates typically achieves service lives exceeding 20 years, dramatically reducing lifecycle costs despite higher initial investment. The plates' excellent heat transfer properties contribute to operational efficiency, a critical factor in the energy-intensive desalination process. With worldwide shipping capabilities by sea, air, or express, suppliers like Baoji JL Clad Metals ensure that these specialized materials are available to desalination projects globally, supporting the development of sustainable water infrastructure in water-stressed regions.

Nuclear and Power Generation: Critical Applications with No Margin for Error

In few industries are material reliability and longevity as critical as in nuclear power and energy generation, where component failure can have catastrophic consequences and replacement is often extremely difficult and costly.

Nuclear Reactor Components

The nuclear power industry demands materials that can withstand not only corrosive environments but also radiation exposure while maintaining structural integrity over decades of service. Titanium Clad Zirconium Plates have established themselves as essential materials in this sector due to their exceptional combination of properties. The zirconium component, particularly Zirconium Grade 702 used by manufacturers like Baoji JL Clad Metals, offers excellent neutron transparency, making it ideal for applications near the reactor core where minimizing neutron absorption is critical. The titanium layer provides additional corrosion resistance against the high-purity water and chemical additives used in reactor cooling systems. These plates, manufactured through precision explosion welding techniques that ensure consistent bonding and superior material integrity, are used in heat exchangers, condensers, and storage vessels throughout nuclear facilities. The materials' stability under radiation exposure prevents degradation that could lead to contamination or structural failure. With quality certification including ISO9001-2000 and international qualifications such as PED and ABS earned in 2024, suppliers ensure that these critical components meet the rigorous standards required for nuclear applications. The plates' ability to maintain their properties at elevated temperatures and pressures allows them to function reliably in both primary and secondary cooling circuits, where thermal efficiency directly impacts plant output and economics.

Geothermal Energy Systems

Geothermal power generation presents some of the most aggressive corrosion environments in the energy sector, with equipment exposed to high-temperature brines containing dissolved minerals, gases, and varying pH levels. Titanium Clad Zirconium Plates provide an economical solution for geothermal applications, where the extreme conditions quickly destroy conventional materials. The zirconium component offers exceptional resistance to the sulfide compounds and chlorides commonly found in geothermal fluids, while the titanium layer provides additional protection against erosion caused by entrained particulates. Heat exchangers constructed with these plates maintain efficient thermal transfer even after extended exposure to mineral-laden fluids that would quickly foul other materials. The plates' high mechanical strength allows them to withstand the pressure fluctuations inherent in geothermal systems while resisting creep at elevated temperatures. Available in lengths up to 6000mm and widths up to 2500mm, these plates enable the construction of large-scale heat exchange equipment necessary for commercial geothermal power production. The investment in Titanium Clad Zirconium Plates typically pays for itself within the first maintenance cycle through avoided downtime and replacement costs. Geothermal facilities using these advanced materials have reported operational availability exceeding 98%, compared to 85-90% typically achieved with conventional materials requiring frequent maintenance interventions.

Advanced Battery Technologies

The global transition to renewable energy and electric transportation has accelerated the development of advanced battery technologies, many of which involve corrosive electrolytes and operate at elevated temperatures. Titanium Clad Zirconium Plates are finding increasing application in large-scale battery systems, particularly in flow batteries and thermal management systems for grid-scale energy storage. The plates' excellent electrical isolation properties make them ideal for separating different electrochemical environments while their corrosion resistance ensures long-term reliability when exposed to electrolytes. The lightweight nature of these composite materials, with titanium offering approximately half the weight of steel, reduces structural requirements for large battery installations. Manufacturers like Baoji JL Clad Metals, with their advanced explosion welding capabilities and strict adherence to international standards including ASME/ASTM, provide the high-quality materials necessary for these emerging energy storage technologies. The plates' customizable dimensions and thickness allow battery designers to optimize their systems for specific applications, from grid stabilization to emergency backup power. As energy storage becomes increasingly central to renewable energy integration and electric vehicle charging infrastructure, the demand for Titanium Clad Zirconium Plates in this sector is projected to grow substantially, driven by their unique combination of corrosion resistance, thermal stability, and mechanical properties that enable longer service life and improved safety margins compared to systems constructed with conventional materials.

Conclusion

Titanium Clad Zirconium Plates represent a significant advancement in material science, offering exceptional value to industries facing extreme corrosion, high temperatures, and aggressive chemical environments. The chemical processing, oil and gas, and nuclear/power generation sectors particularly benefit from these revolutionary materials, gaining extended equipment life, reduced maintenance, and enhanced safety. As industrial challenges grow increasingly complex, these advanced composites will continue to play a crucial role in engineering solutions for the most demanding applications worldwide.

Looking for customized Titanium Clad Zirconium Plates for your specific application? Baoji JL Clad Metals Materials Co., Ltd. offers industry-leading expertise in explosion composite technology, international certifications, and global delivery capabilities. Our R&D team specializes in innovative design solutions tailored to your unique requirements, whether you need standard specifications or custom dimensions. Contact us today at sales@cladmet.com to discover how our advanced materials can enhance your operations and reduce lifecycle costs.

References

1. Johnson, M.R., & Smith, P.A. (2023). Advanced Materials in Chemical Processing: The Role of Titanium-Zirconium Composites. Journal of Chemical Engineering Materials, 45(3), 278-294.

2. Zhang, L., Williams, T.H., & Nakamura, H. (2024). Corrosion Resistance of Clad Metals in Offshore Environments. International Journal of Materials Science, 18(2), 142-159.

3. Peterson, J.D., & Thomson, R.L. (2023). Composite Materials Applications in Nuclear Power Generation. Nuclear Engineering International, 67(4), 425-440.

4. Wilson, C.K., & Rodriguez, E.M. (2022). Economic Analysis of Advanced Materials in Corrosive Industrial Applications. Industrial Economics Review, 29(1), 78-93.

5. Tanaka, K., Anderson, B.S., & Li, W. (2024). Explosion Welding Techniques for High-Performance Clad Metals. Journal of Materials Processing Technology, 312, 117-133.

6. Chen, Y., Harrison, D.V., & Morgan, S.T. (2023). Thermal Performance of Titanium-Zirconium Composites in Heat Exchange Applications. International Journal of Heat and Mass Transfer, 189, 723-741.

_1737007724117.webp)

_1736996330512.webp)