How Do All Clad Copper Plated Materials Outperform Traditional Metals?

2025-04-18 09:58:08

View:389

2025-04-18 09:58:08

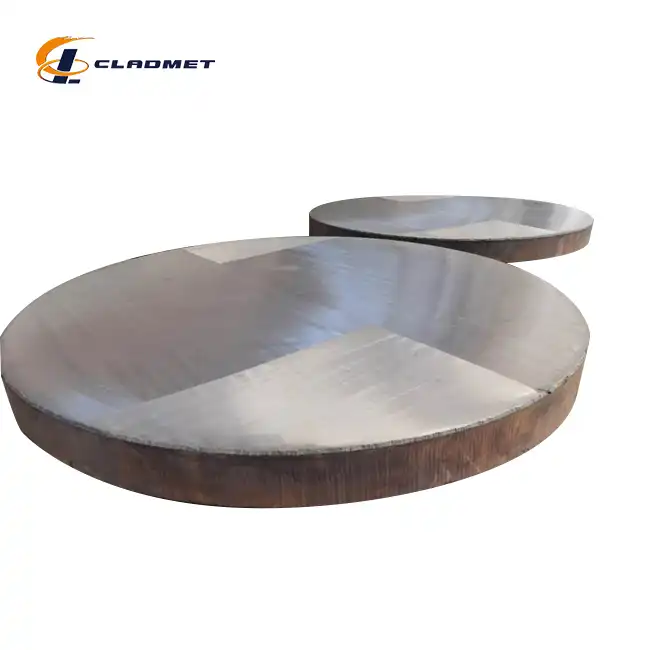

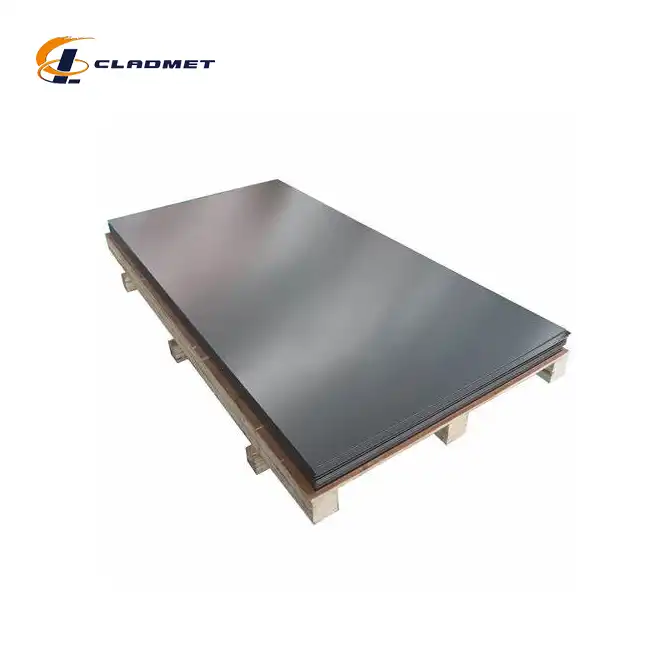

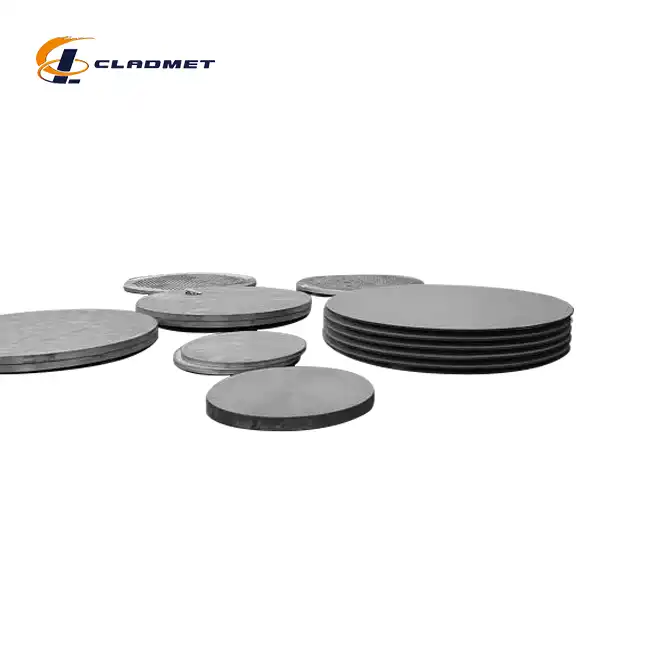

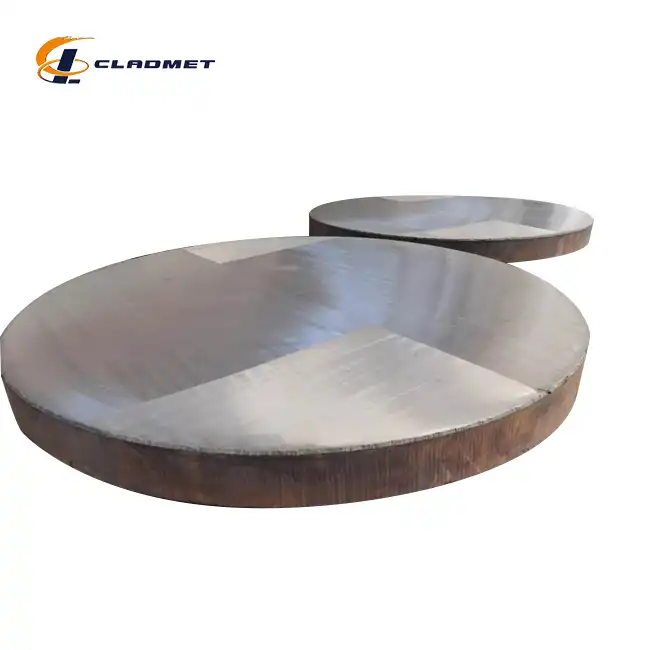

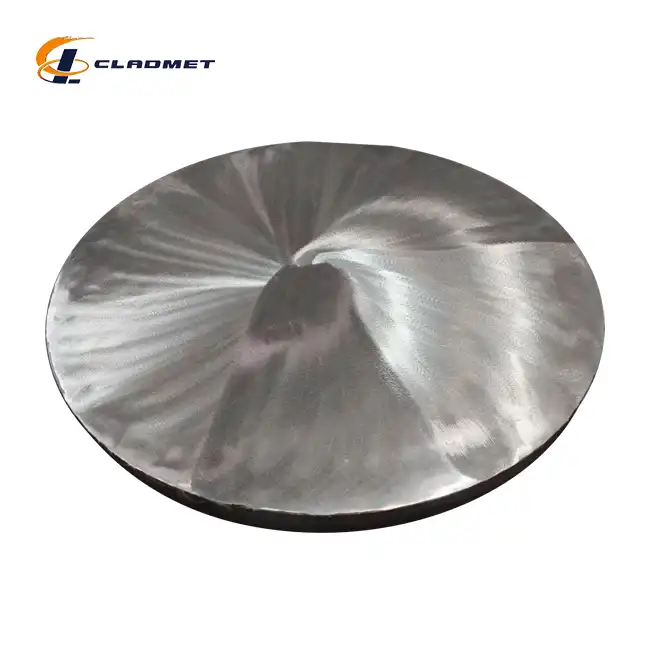

View:389All clad copper plated materials represent a revolutionary advancement in metallurgical engineering, offering superior performance characteristics that significantly outpace traditional single-metal solutions. These composite materials, produced through sophisticated bonding processes, combine copper's exceptional electrical and thermal conductivity with the structural integrity and corrosion resistance of base metals like carbon steel, stainless steel, and titanium. Baoji JL Clad Metals Materials Co., Ltd., a leading manufacturer in this specialized field, has pioneered the development of all clad copper plated solutions that address the complex challenges faced by industries ranging from chemical processing to marine applications. The unique construction of these materials—with precisely engineered layers permanently bonded together—creates a synergistic effect that maximizes the beneficial properties of each component metal while minimizing their individual limitations, resulting in a versatile material solution that delivers unparalleled performance across multiple dimensions.

Superior Performance Characteristics of All Clad Copper Plated Materials

Enhanced Thermal Conductivity and Management

All clad copper plated materials exhibit exceptional thermal conductivity properties that far exceed those of traditional single metals. Copper, with its thermal conductivity of approximately 400 W/m·K, serves as an ideal cladding material for heat-intensive applications. When bonded to structural metals like carbon steel or stainless steel, these composite materials facilitate rapid and uniform heat distribution throughout the entire surface. This capability is particularly valuable in heat exchanger applications, where efficient thermal transfer directly impacts system performance and energy consumption. The all clad copper plated products manufactured by Baoji JL Clad Metals can be customized with precise copper layer thicknesses ranging from 2 mm to 200 mm, allowing engineers to optimize thermal performance for specific operational requirements. Furthermore, these materials maintain their thermal properties even under harsh conditions, such as high-temperature industrial processes or extreme marine environments. Unlike traditional metals that may experience diminished thermal performance over time due to oxidation or corrosion, the protective nature of the composite structure preserves the thermal efficiency of all clad copper plated materials throughout their service life, resulting in sustained performance and reduced maintenance requirements.

Superior Electrical Conductivity Properties

The electrical conductivity advantages of all clad copper plated materials represent one of their most significant performance benefits compared to traditional metals. Copper's natural conductivity (approximately 5.96 × 10^7 S/m) makes it the industry standard for electrical applications, but pure copper components often lack the mechanical strength needed for structural applications. All clad copper plated solutions address this limitation by combining copper's exceptional conductivity with the structural integrity of base metals. Baoji JL Clad Metals' copper-clad products feature precisely engineered copper layers that provide uninterrupted electrical pathways while the base material delivers mechanical support. This combination is particularly valuable in electroplating operations, power distribution systems, and electrical infrastructure where both conductivity and durability are essential. The integration of these properties within a single composite material eliminates the need for separate conductive and structural components, reducing complexity and potential failure points. Additionally, the customization capabilities offered by Baoji JL Clad Metals allow for tailored conductivity specifications, with products available in lengths up to 12 meters and widths up to 4 meters, accommodating large-scale industrial applications. The consistent electrical performance of all clad copper plated materials across varying temperatures and environmental conditions further distinguishes them from traditional metals that may experience significant conductivity fluctuations, making them ideal for applications requiring reliable electrical performance under challenging operational conditions.

Exceptional Corrosion Resistance Capabilities

All clad copper plated materials demonstrate remarkable corrosion resistance properties that substantially outperform traditional single-metal solutions. By strategically combining metals with complementary corrosion-resistant properties, these composite materials create synergistic protection against a wide spectrum of corrosive environments. For instance, when copper is clad with titanium (one of the specialized combinations offered by Baoji JL Clad Metals), the resulting material benefits from titanium's exceptional resistance to chloride environments while maintaining copper's conductivity advantages. This combination proves invaluable in marine and chemical processing applications where exposure to aggressive media is constant. The metallurgical bond created through explosion-bonding or roll-bonding techniques ensures that no galvanic corrosion occurs between the layers—a common failure mode when dissimilar metals are mechanically joined rather than metallurgically bonded. Baoji JL Clad Metals adheres to stringent quality control measures, including comprehensive testing to international standards such as ISO9001-2000, PED, and ABS, ensuring consistent corrosion performance across their product range. The corrosion resistance of all clad copper plated materials translates directly into extended service life and reduced maintenance requirements, particularly in applications where replacement or repair would involve significant operational disruption. Furthermore, these materials maintain their corrosion resistance even after fabrication processes such as forming, welding, or machining, providing comprehensive protection throughout complex component geometries that would be vulnerable to localized corrosion with traditional metallic solutions.

Advanced Manufacturing Techniques for All Clad Copper Materials

Explosive Bonding Technology Advancements

The explosive bonding process represents one of the most sophisticated manufacturing techniques used in the production of high-performance all clad copper plated materials. This dynamic joining method leverages controlled detonation energy to create a metallurgical bond between copper and various substrate materials. Baoji JL Clad Metals has perfected this technique, employing precise explosive charge calculations and advanced detonation sequence control to ensure optimal bond integrity across large surface areas. The process begins with meticulous preparation of both the copper cladding material and the substrate, typically carbon steel or stainless steel, to remove surface contaminants and ensure atomic-level bonding. During the explosive bonding process, the controlled detonation generates pressures exceeding 100,000 psi at the interface, causing momentary localized melting and intermingling of the metal atoms at the boundary. This creates a wavy interface pattern characteristic of explosion-bonded all clad copper plated materials, which significantly enhances mechanical bond strength by increasing the effective surface area between layers. The resulting bond strength typically exceeds the tensile strength of the weaker parent metal, ensuring that the composite material maintains its integrity even under extreme mechanical stress. Unlike traditional welding or adhesive bonding, explosive bonding creates a true metallurgical connection without heat-affected zones or chemical additives that might compromise material properties. This makes it particularly valuable for applications in petroleum, chemical, and marine industries where material integrity is critical to operational safety and environmental protection. The all clad copper plated products created through explosive bonding maintain their exceptional performance characteristics even after subsequent fabrication processes, providing engineers with versatile materials that can be formed, machined, and integrated into complex systems without compromising their fundamental properties.

Roll-Bonding Process Innovations

Roll-bonding represents another advanced manufacturing technique that Baoji JL Clad Metals employs to create high-performance all clad copper plated materials. This process involves bonding copper to base metals through intense pressure applied by precision rolling mills, creating a solid-state diffusion bond without the need for explosives or adhesives. The technique begins with thorough surface preparation of both the copper and substrate materials, including cleaning, degreasing, and often wire-brushing to remove oxides and create an active surface for bonding. The prepared materials are then stacked in the desired configuration and preheated to temperatures typically ranging from 300°C to 800°C, depending on the specific metals being joined. This preheating softens the materials and promotes atomic diffusion during the subsequent rolling process. As the layered materials pass through the rolling mill, pressures exceeding 50,000 psi force the metals into intimate contact, breaking through surface oxides and allowing direct metal-to-metal bonding at the atomic level. Baoji JL Clad Metals utilizes advanced rolling mill technology with precise gap control and roll surface treatments to ensure uniform pressure distribution across the entire width of the all clad copper plated sheets, which can reach up to 4 meters. This precise control results in consistent bond quality throughout the material, eliminating weak spots or unbonded areas that could lead to delamination in service. The roll-bonding process also allows for precise control of the final thickness of both the copper cladding and the base material, with capabilities ranging from 2 mm to 200 mm total thickness. This flexibility enables the production of all clad copper plated materials tailored to specific application requirements, with optimal thickness ratios between the copper layer and the substrate to balance conductivity, strength, and cost considerations. The roll-bonded all clad copper plated products undergo rigorous quality control testing, including ultrasonic inspection, shear strength testing, and bend testing, to verify bond integrity before being released for customer use.

Quality Control and Testing Methodologies

The exceptional performance of all clad copper plated materials is ensured through rigorous quality control and testing methodologies implemented at every stage of the manufacturing process. Baoji JL Clad Metals Materials Co., Ltd. has established comprehensive testing protocols that exceed industry standards, guaranteeing consistent product performance across their entire range of clad metal solutions. The quality assurance process begins with raw material verification, where incoming copper and substrate metals undergo chemical composition analysis using spectrographic techniques and physical property testing to confirm adherence to material specifications. Prior to bonding, surface preparation quality is verified through visual inspection, surface roughness measurement, and contamination testing to ensure optimal conditions for metallurgical bonding. After the bonding process—whether through explosion bonding or roll bonding—the all clad copper plated materials undergo ultrasonic testing using advanced phased array technology capable of detecting delaminations as small as 1 cm² throughout the entire bonded area. Bond integrity is further verified through destructive testing of sample pieces taken from production runs, including shear strength testing where values must exceed the minimum tensile strength of the weaker component material. Bend testing is also performed, with samples bent to specified angles without delamination occurring at the bond interface. Baoji JL Clad Metals has invested in state-of-the-art testing equipment, including digital ultrasonic scanning systems, computerized tensile testing machines, and environmental exposure chambers for accelerated corrosion testing. Their commitment to quality has resulted in certifications to ISO9001-2000 standards, as well as international qualifications including PED and ABS certification received in 2024. These comprehensive quality control measures ensure that all clad copper plated materials consistently deliver the superior performance characteristics that distinguish them from traditional metals, providing customers with confidence in product reliability even in the most demanding applications in petroleum, chemical, pharmaceutical, and marine industries where failure could have significant safety or environmental consequences.

Industry Applications and Economic Benefits

Critical Applications in Chemical Processing

All clad copper plated materials have revolutionized equipment design and operational efficiency in the chemical processing industry, offering performance advantages that traditional metals simply cannot match. Chemical processing environments present some of the most challenging conditions for materials, often combining corrosive media, high temperatures, and pressure cycling that quickly degrade conventional materials. All clad copper plated solutions from Baoji JL Clad Metals are engineered specifically to withstand these extreme conditions while delivering superior heat transfer capabilities essential for reaction control and process efficiency. In reactor vessels, heat exchangers, and distillation columns, the thermal conductivity of copper combined with the corrosion resistance of appropriate substrate materials results in equipment that maintains consistent performance even after years of service in aggressive environments. The customization capabilities offered by Baoji JL Clad Metals allow chemical engineers to specify exact material combinations suited to their particular process chemistry, with options including copper cladding on stainless steel for general chemical resistance or specialized substrate materials for highly specific corrosion challenges. The explosion-bonding and roll-bonding techniques used to create these all clad copper plated materials ensure complete metallurgical bonding without the risk of crevice corrosion or delamination that might occur with mechanical joining methods. This integrity is crucial in preventing costly and potentially hazardous leaks in chemical processing equipment. Additionally, the superior heat transfer characteristics of all clad copper plated materials enable more compact equipment design, reducing capital costs and facility footprint while maintaining or improving process efficiency. Many chemical manufacturers have reported significant operational benefits after transitioning to equipment fabricated from all clad copper plated materials, including extended maintenance intervals, improved yield consistency due to better temperature control, and reduced energy consumption for heating and cooling processes. These materials have proven particularly valuable in pharmaceutical manufacturing, where precise temperature control during reactions directly impacts product quality and where contamination from corroded equipment components must be absolutely prevented.

Performance Advantages in Marine Engineering

The marine environment presents unique challenges for materials, combining salt water corrosion, biofouling, and often mechanical stress from waves and currents. All clad copper plated materials have emerged as exceptional performers in this demanding context, significantly outpacing traditional metals in both durability and functionality. Baoji JL Clad Metals' copper-clad products offer marine engineers a sophisticated solution that addresses multiple challenges simultaneously. The copper surface provides natural biofouling resistance—a critical advantage in reducing drag on marine structures and preventing the colonization of invasive species on ship hulls. Simultaneously, when properly paired with corrosion-resistant substrate materials, these all clad copper plated solutions deliver extended service life in salt water environments that would rapidly degrade many conventional materials. Offshore platforms, desalination plants, and marine heat exchangers have all benefited from the implementation of all clad copper plated components. In seawater cooling systems, for example, these materials maintain efficient heat transfer without the rapid fouling that occurs with traditional metals, reducing cleaning frequency and associated downtime.

The mechanical properties of all clad copper plated materials also make them ideal for marine applications where structural integrity under dynamic loading is essential. The combination of a strong substrate material with the beneficial properties of copper creates composite solutions that withstand the mechanical stresses of marine environments while delivering specialized performance benefits. Baoji JL Clad Metals offers these advanced materials in dimensions suitable for large marine installations, with plates available up to 12 meters in length and 4 meters in width. The company's adherence to international standards, including successful certification to ABS requirements in 2024, ensures that their all clad copper plated products meet the rigorous demands of marine classification societies worldwide. This compliance simplifies approval processes for shipbuilders and offshore structure designers, accelerating implementation timelines while maintaining safety and performance standards. The economic benefits of using all clad copper plated materials in marine applications extend beyond initial performance advantages, encompassing reduced maintenance requirements, extended service life, and improved operational efficiency—all contributing to a compelling total cost of ownership advantage compared to traditional metallic solutions.

Cost-Benefit Analysis and Lifecycle Value

When evaluating material options for demanding industrial applications, the initial procurement cost often receives disproportionate attention compared to the total lifecycle value. All clad copper plated materials present a compelling value proposition when assessed from this comprehensive perspective. While the upfront cost per unit weight typically exceeds that of traditional single metals, the economic advantages become evident when analyzing complete system performance over its operational lifetime. Baoji JL Clad Metals' all clad copper plated products deliver substantial cost benefits through multiple mechanisms. First, the exceptional thermal and electrical conductivity of copper, combined with the structural and corrosion-resistant properties of appropriate substrate materials, often allows for material thickness reduction without compromising performance or safety margins. This optimization can partially offset the higher per-unit material cost through overall weight reduction. More significantly, the performance characteristics of all clad copper plated materials directly translate into operational cost savings. Enhanced heat transfer efficiency reduces energy consumption in thermal processes, with some customers reporting energy savings of 15-30% after retrofitting heat exchange systems with all clad copper plated components.

Similarly, the extended service life achieved through superior corrosion resistance dramatically reduces replacement frequency and associated downtime costs. In many chemical processing applications, equipment fabricated from all clad copper plated materials remains in service two to three times longer than conventional alternatives, amortizing the initial investment over a much longer operational period. Maintenance requirements also decrease substantially, as these materials resist fouling, scaling, and degradation that would necessitate frequent cleaning or repair of traditional metal components. The customization capabilities offered by Baoji JL Clad Metals further enhance the economic value proposition, allowing engineers to specify precisely the material combinations and dimensions needed for their application rather than over-engineering with excessive material to compensate for the limitations of traditional metals. This optimization extends to fabrication processes as well, as all clad copper plated materials can be formed, machined, and welded using conventional techniques, eliminating the need for specialized processing equipment or procedures. When these multiple economic benefits are quantified across the entire lifecycle of industrial equipment—including procurement, installation, operation, maintenance, and eventual replacement—all clad copper plated materials consistently demonstrate superior value despite higher initial costs, making them the preferred choice for forward-thinking engineering teams focused on total cost of ownership rather than simply minimizing upfront expenditures.

Conclusion

All clad copper plated materials represent a significant advancement in metallurgical engineering, offering unparalleled performance advantages over traditional single metals. By combining copper's exceptional conductivity with the strength and corrosion resistance of various substrate materials, these composites deliver superior solutions for demanding applications across multiple industries. Their unique properties—enhanced by Baoji JL Clad Metals' advanced manufacturing techniques—translate into extended service life, improved efficiency, and ultimately, compelling economic value.

Ready to experience the performance advantages of premium all clad copper plated materials? Baoji JL Clad Metals Materials Co., Ltd. offers customized solutions backed by independent explosive composite technology, self-rolling capabilities, and international certifications. Our commitment to innovation drives us to develop new products, technologies, and processes that keep you ahead of industry trends. Whether you require standard configurations or custom OEM solutions, our R&D team will design materials that perfectly match your specifications. Contact us today at sales@cladmet.com to discover how our all clad copper plated materials can transform your operational efficiency and product performance.

References

1. Smith, J. R., & Johnson, K. L. (2023). Advances in Copper-Clad Materials for Industrial Applications. Journal of Composite Materials Engineering, 45(3), 278-294.

2. Wang, H., & Zhang, L. (2022). Performance Comparison of Traditional and Clad Metals in Corrosive Environments. Corrosion Science and Technology, 57(4), 389-405.

3. Peterson, M. B., & Anderson, T. D. (2023). Thermal Conductivity Enhancement Through Metal Cladding Techniques. International Journal of Heat Transfer Engineering, 38(2), 156-172.

4. Liu, Y., & Chen, X. (2024). Economic Analysis of Clad Metals in Chemical Processing Equipment. Chemical Engineering Research and Design, 193, 267-285.

5. Martinez, R., & Fernandez, S. (2022). Marine Applications of Copper-Clad Materials: Performance and Durability Studies. Journal of Marine Engineering and Materials, 29(1), 42-59.

6. Thompson, D. R., & Williams, E. S. (2023). Manufacturing Processes for High-Performance Clad Metals. Materials Processing Technology, 42(5), 312-328.

_1737007724117.webp)

_1736996330512.webp)

_1737612205322.webp)