Superior corrosion resistance in harsh environments.

Biocompatible for medical implant applications.

Lightweight with high-performance stability.

Heat and wear resistance for durability.

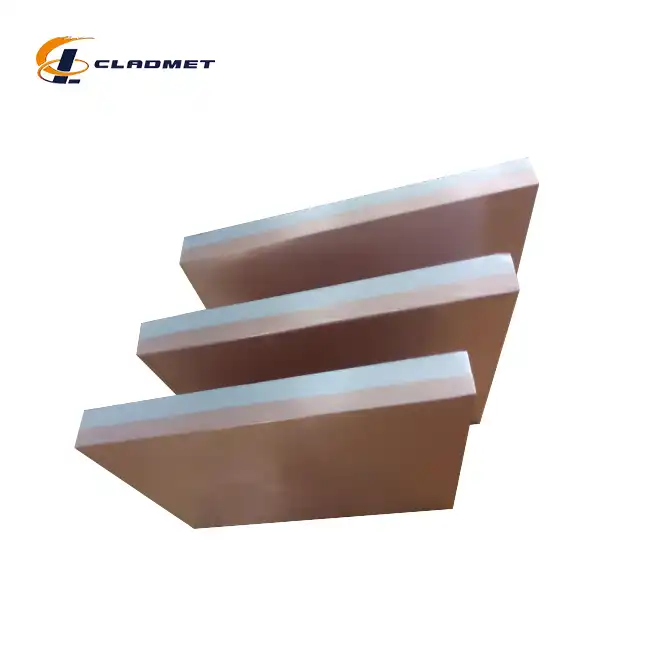

Product Introduction

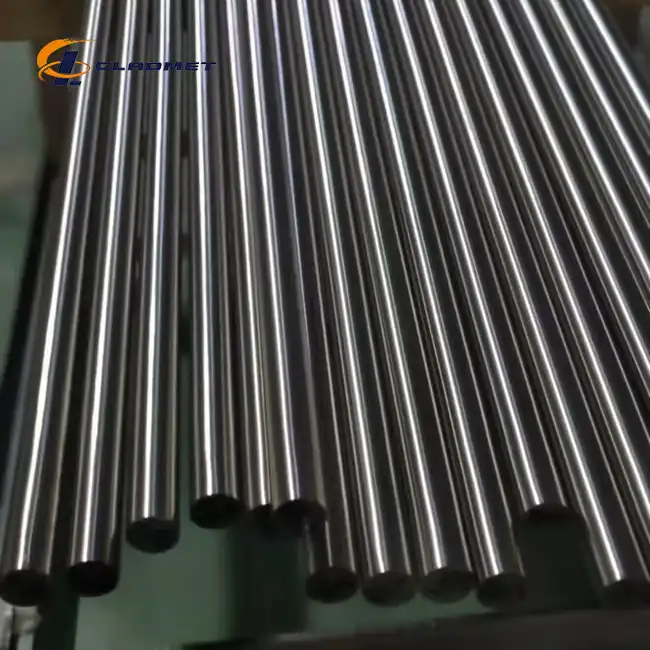

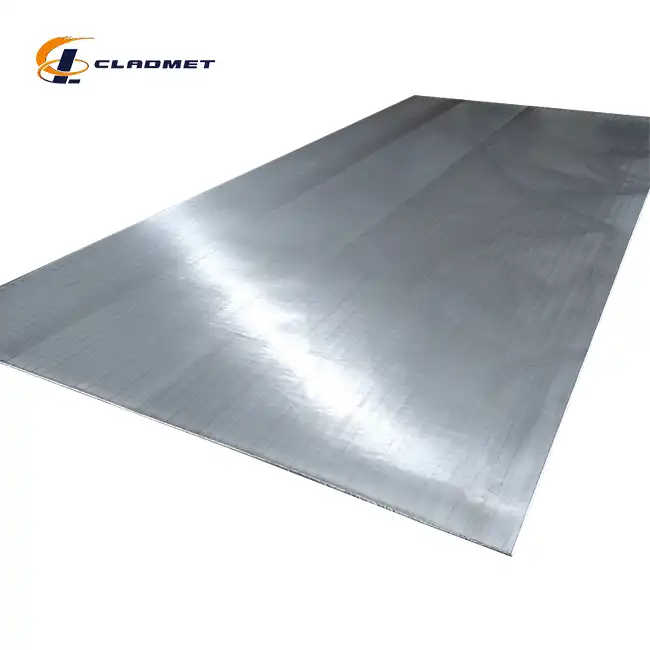

GR23 Titanium Rod is a high-strength, lightweight, and corrosion-resistant titanium alloy designed for various industrial applications. As an advanced medical-grade alloy (Ti-6Al-4V ELI), GR23 titanium offers excellent biocompatibility, making it ideal for medical implants, aerospace, and high-performance engineering industries. With superior mechanical properties and excellent resistance to harsh environments, this titanium rod ensures durability and reliability in demanding conditions.

Product Specifications

| Product Name | GR23 Titanium Rod |

|---|---|

| Material Classification | Titanium Alloy |

| Material | Ti-6Al-4V ELI |

| Shape | Rod/Bar |

| Alloy Type | Alpha-Beta Alloy |

| Standard | ASTM B348, AMS 4907, ISO 5832-3 |

| Production Process | Hot Rolling, Cold Rolling, Annealing |

| Diameter Range | 3mm – 100mm |

| Length | Customizable (1m – 6m) |

| Product Application Industry | Medical, Aerospace, Automotive, Chemical Processing, Marine |

| Packaging Method | Wooden Cases, Plastic Wrapping, Carton Box |

| Transportation | Air, Sea, Express |

| Delivery Cycle | 10-30 Days Depending on Order Volume |

|

|

|

Product Application Industry

GR23 Titanium Rod is widely used in various industries, including:

Medical Industry: Dental implants, orthopedic implants, surgical instruments.

Aerospace Industry: Aircraft structural components, engine parts, and fasteners.

Automotive Industry: High-performance racing components and exhaust systems.

Chemical Processing: Heat exchangers, reactors, and piping systems resistant to corrosion.

Marine Industry: Shipbuilding components and offshore oil and gas applications.

Product Manufacturing Process

Raw Material Selection – High-quality titanium sponge is used to ensure material purity.

Melting – Vacuum arc remelting (VAR) or electron beam melting (EBM) for uniformity.

Forging & Rolling – Hot rolling and cold rolling processes enhance mechanical properties.

Heat Treatment – Annealing to optimize strength and ductility.

Precision Machining – Grinding, polishing, and cutting for final dimensions.

Inspection & Testing – Ultrasonic testing, tensile strength analysis, and chemical composition testing.

Packaging & Delivery – Secure packaging to ensure safe transportation to global clients.

Test report

|

|

|

|

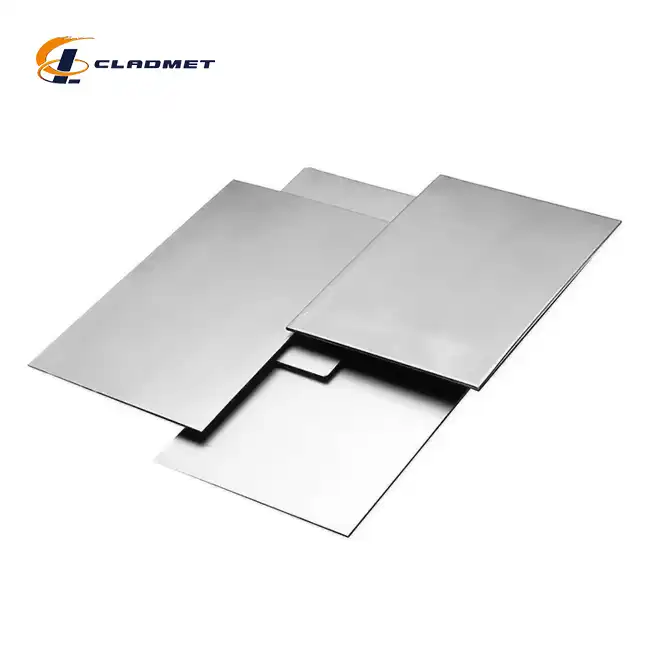

OEM Service

We provide customized OEM services for GR23 Titanium Rod to meet specific client requirements, including:

Custom dimensions and surface finishes

Private labeling and branding

Special alloy compositions based on industrial needs

Technical support and consultation

FAQ

Q1: What makes GR23 titanium different from other titanium alloys? A1: GR23 (Ti-6Al-4V ELI) has lower interstitial elements, making it more biocompatible and corrosion-resistant, ideal for medical and aerospace applications.

Q2: Can you provide third-party inspection reports? A2: Yes, we offer third-party inspection services upon request to ensure product quality.

Q3: What is the lead time for bulk orders? A3: Our standard lead time is 10-30 days, depending on order volume and customization requirements.

Q4: Do you ship internationally? A4: Yes, we have a strong global supply chain and ship worldwide via air, sea, and express services.

Q5: How can I place an order? A5: Contact us via email, WhatsApp, or phone, and our sales team will assist you with the purchasing process.

Contact Us

Tel: +86-917-3372918

WhatsApp: +8613530170059

Email: sales@cladmet.com

Address: FENGHUANG 4 ROAD, HIGH-TECH DISTRICT, BAOJI CITY, SHAANXI, CHINA 721013

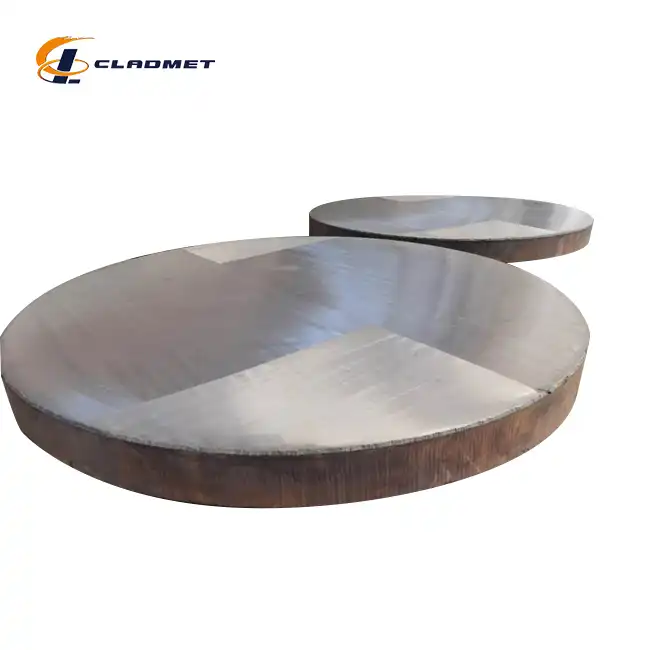

Our Factory

Production Site

Hot Rolling

Hot Rolling

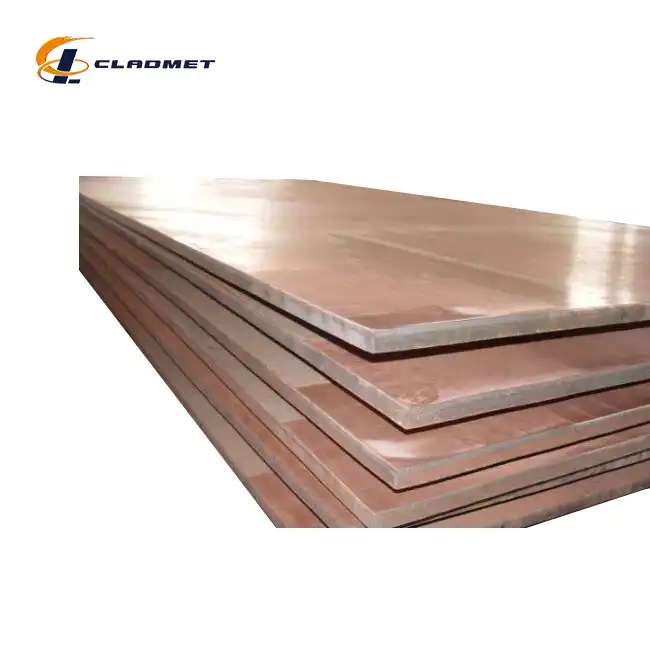

Main Products

Main Application Industries

_1737007724117.webp)