Applications of Titanium Clad Metals in the Aerospace Industry

2024-12-18 10:55:37

View:389

2024-12-18 10:55:37

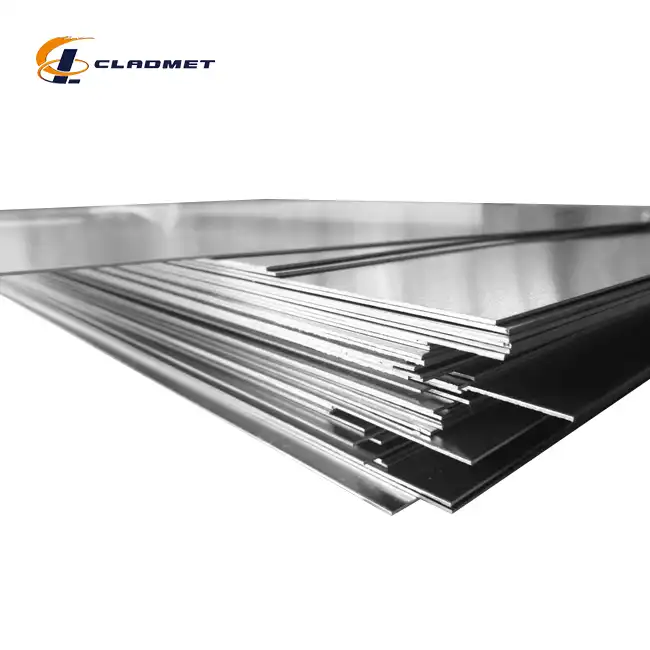

View:389Titanium and its alloys are critical materials in the aerospace industry due to their exceptional strength-to-weight ratio, corrosion resistance, and high-temperature stability. Baoji JL Clad Metals Materials Co., Ltd., a leading manufacturer in China, specializes in producing titanium clad metals that are widely applied in various aerospace applications. The company’s long-standing focus on research and development, along with its advanced manufacturing capabilities, ensures that it remains at the forefront of this vital sector.

Advantages of Titanium Clad Metals in Aerospace Applications

Lightweight and Strong

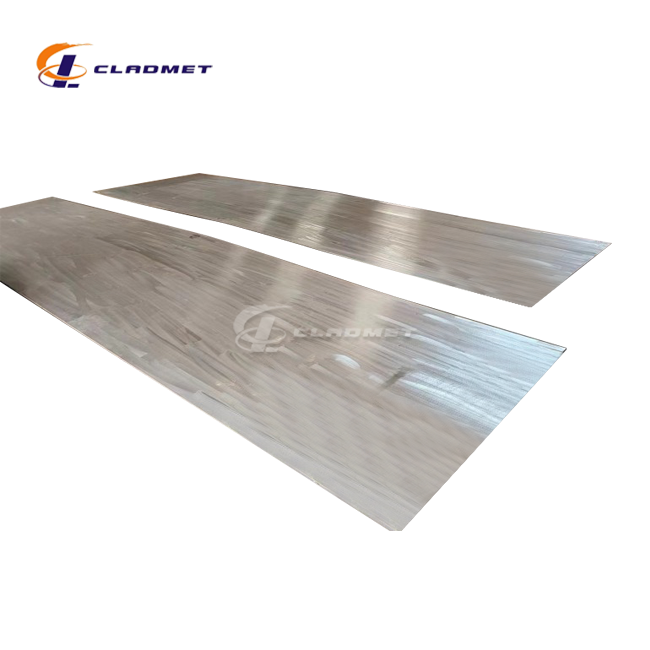

Titanium's high strength combined with its low density makes it an ideal material for aerospace applications, where weight reduction is essential for improving fuel efficiency and payload capacity. Titanium clad metals, which combine titanium with other metals like aluminum or stainless steel, offer a cost-effective solution without sacrificing the strength and durability required in aerospace components.

Corrosion Resistance

Aerospace components are often exposed to harsh environments, including high levels of moisture, temperature extremes, and chemical exposure. Titanium's natural resistance to corrosion ensures that components such as fuselages, turbine blades, and fasteners remain durable and reliable even in challenging conditions.

High-Temperature Performance

Titanium alloys, particularly those used in high-performance aerospace applications, offer excellent resistance to high temperatures, making them suitable for parts like engine components, heat shields, and exhaust systems. Titanium-clad materials maintain their structural integrity in extreme temperatures, reducing the risk of failure during operation.

Key Aerospace Applications of Titanium Clad Metals

Aircraft Structures

Titanium clad metals are extensively used in the construction of aircraft structures, including fuselages, wings, and tail sections. These components require materials that offer both strength and lightness. Titanium’s combination of strength and low weight makes it ideal for minimizing the overall weight of the aircraft while maintaining structural integrity.

Engine Components

Titanium alloys are essential in aerospace engines, where high strength and resistance to heat and corrosion are critical. Titanium clad metals are often used in turbine blades, compressors, and casings in jet engines. These parts must withstand extreme temperatures and mechanical stress, making titanium an optimal choice for performance and longevity.

Landing Gear

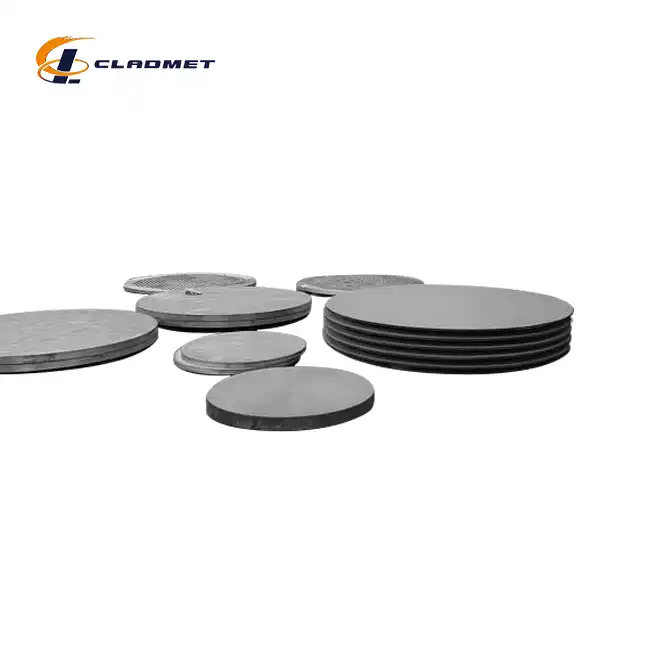

The landing gear of aircraft must be both strong and lightweight to withstand heavy loads during takeoff and landing while also resisting corrosion from moisture and chemicals. Titanium-clad materials, with their high strength and resistance to wear, are increasingly used in landing gear components such as struts and wheels.

Spacecraft and Satellites

In space applications, where materials are subjected to both high heat and the vacuum of space, titanium’s ability to resist thermal expansion and withstand extreme temperatures makes it highly suitable. Titanium clad metals are used in spacecraft structures, fuel tanks, and satellite components, ensuring the reliability and longevity of critical equipment in space missions.

Fasteners and Fittings

Titanium-clad fasteners and fittings are essential in aerospace applications where strength, light weight, and corrosion resistance are paramount. These fasteners are used in various structural assemblies, ensuring secure connections while reducing the overall weight of the aircraft or spacecraft.

Conclusion

Titanium clad metals play a vital role in the aerospace industry due to their superior properties of strength, corrosion resistance, and lightweight nature. Baoji JL Clad Metals Materials Co., Ltd. provides high-performance titanium clad products that meet the rigorous standards required for aerospace applications. Their advanced manufacturing processes and commitment to research and development ensure that their products support the demanding needs of the aerospace industry, making them a trusted partner for aerospace manufacturers worldwide.

_1737007724117.webp)

_1736996330512.webp)