Applications of Titanium Clad Metals in the Petroleum and Energy Industry

2024-12-18 10:54:20

View:389

2024-12-18 10:54:20

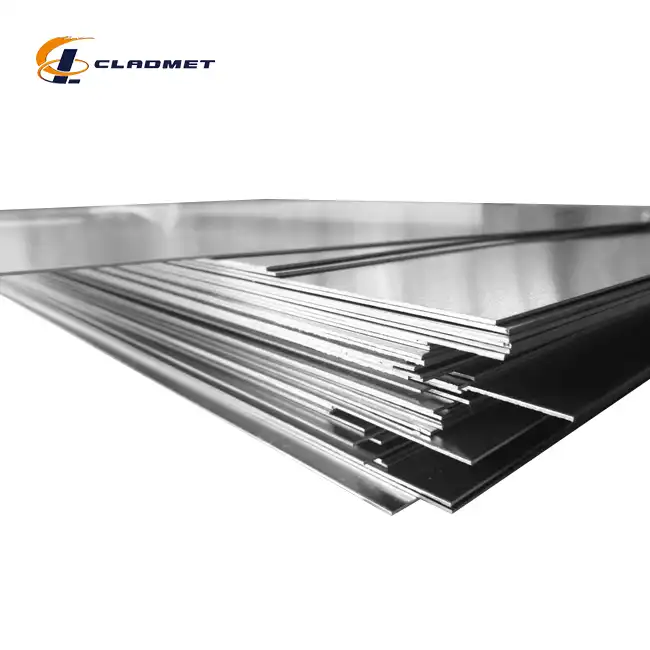

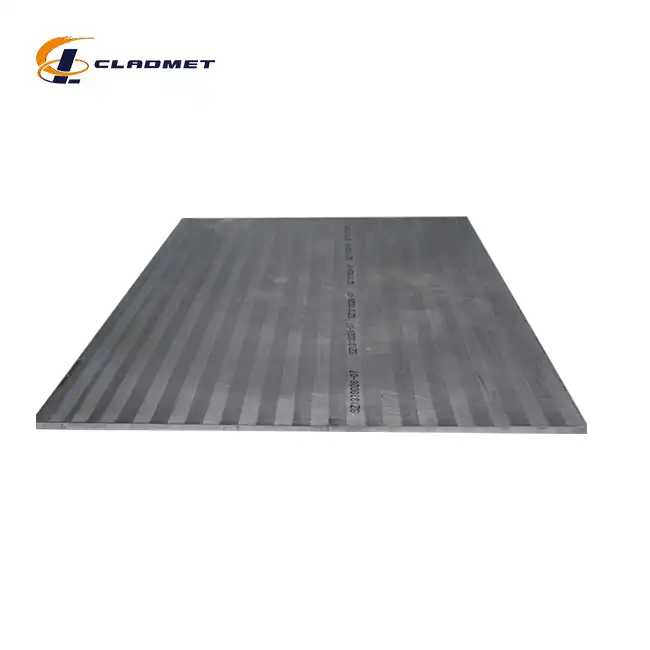

View:389Titanium clad metals are becoming increasingly essential in the petroleum and energy industries due to their superior corrosion resistance, strength, and cost-effectiveness. Baoji JL Clad Metals Materials Co., Ltd., a leading manufacturer in China with over 36 years of experience, specializes in producing high-quality titanium clad materials used extensively in these sectors.

Advantages of Titanium Clad Metals in Petroleum and Energy Applications

Corrosion Resistance

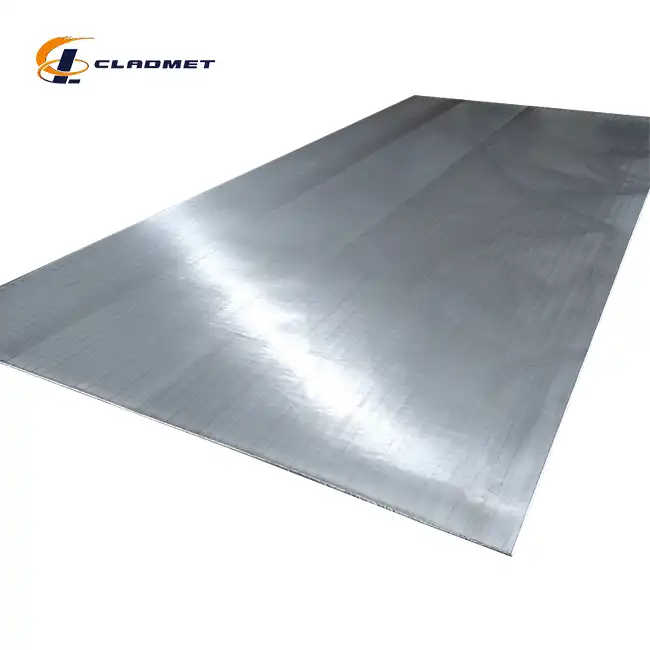

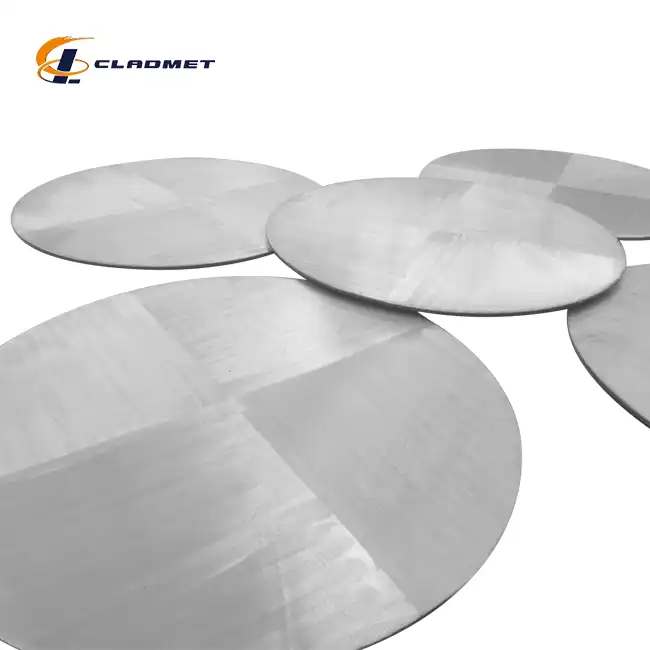

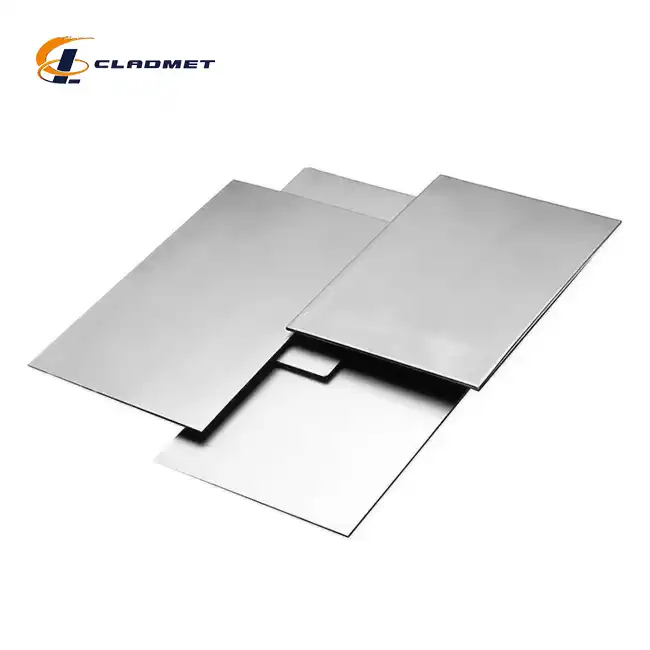

The petroleum and energy industries often deal with highly corrosive environments, including harsh chemicals, acids, and high temperatures. Titanium, with its exceptional resistance to corrosion, is ideal for applications in oil and gas extraction, refining, and energy production. Titanium clad metals provide an affordable solution by combining the corrosion resistance of titanium with the structural strength of other base metals, such as stainless steel and aluminum.

Durability Under Extreme Conditions

Titanium clad metals excel in environments that subject materials to extreme temperatures and pressures. In the energy industry, where equipment is exposed to intense conditions, titanium cladding ensures long-term performance and prevents material degradation.

Cost-Effectiveness

Using titanium clad metals offers significant cost savings compared to pure titanium. The bonding of titanium with lower-cost materials like stainless steel or nickel allows for a high-performance solution at a reduced price, without compromising the strength and durability needed for challenging petroleum and energy applications.

Key Applications in Petroleum and Energy Sectors

Oil & Gas Extraction Equipment

Titanium clad materials are widely used in oil rigs, pipelines, and equipment exposed to aggressive offshore and onshore environments. Titanium’s ability to withstand harsh conditions such as seawater and sulfur-containing compounds makes it ideal for drilling systems, pumps, and valves in the petroleum industry.

Heat Exchangers

Heat exchangers in the petroleum and energy industries are exposed to aggressive fluids and high temperatures. Titanium clad heat exchangers provide reliable heat transfer while preventing corrosion from oils, acids, and gases, ensuring long service life and efficiency.

Desalination Systems

In energy production and water treatment, desalination systems often use titanium-clad components due to their resistance to saltwater corrosion. Titanium clad metals are used in desalination plants for pipes, pumps, and pressure vessels, ensuring that these systems operate effectively in seawater environments.

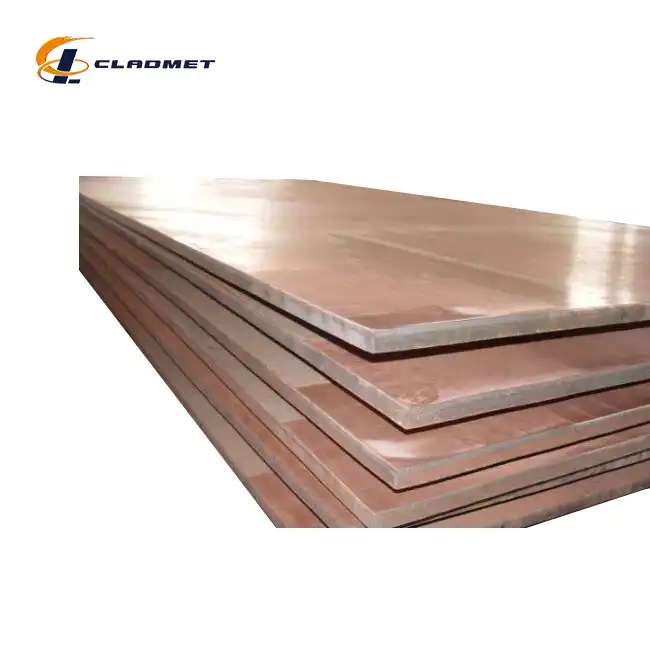

Piping Systems and Storage Tanks

Titanium clad pipes and storage tanks are critical in the transportation and storage of crude oil, natural gas, and other petrochemicals. The high strength and corrosion resistance of titanium ensure that these systems remain operational in the face of aggressive chemicals, high pressure, and temperature fluctuations.

Refining Equipment

Titanium clad materials are used in refining equipment such as reactors, distillation columns, and filtration units. They help maintain the integrity and efficiency of these systems, which often process corrosive substances like acids, alkalis, and hydrocarbons.

Conclusion

Titanium clad metals play a crucial role in the petroleum and energy industries by offering superior corrosion resistance, durability, and cost savings. Baoji JL Clad Metals Materials Co., Ltd. provides high-quality titanium clad products that meet international standards and are used across the oil and gas sector, energy production, and desalination. Their application in critical equipment ensures long-term reliability and performance, making titanium-clad materials a preferred choice for these industries.

_1737007724117.webp)

_1736996330512.webp)