What are the Benefits of Using Titanium Clad Zirconium Plates over Solid Titanium or Zirconium Plates?

2025-04-02 13:42:44

View:389

2025-04-02 13:42:44

View:389In today's demanding industrial environments, material selection plays a crucial role in determining operational efficiency, equipment lifespan, and overall cost-effectiveness. Titanium Clad Zirconium Plates represent a revolutionary advancement in materials engineering, offering superior performance characteristics compared to their single-metal counterparts. These innovative composite materials combine the exceptional properties of both titanium and zirconium, delivering unparalleled benefits in corrosion resistance, mechanical strength, and economic efficiency. By strategically layering these metals through sophisticated cladding processes, manufacturers like Baoji JL Clad Metals Materials Co., Ltd. have developed materials that overcome the limitations of solid titanium or zirconium plates while capitalizing on their respective strengths. This article explores the multifaceted advantages of Titanium Clad Zirconium Plates and why they have become the material of choice for industries facing extreme operational conditions.

Economic and Performance Advantages of Composite Plate Construction

Cost-Effectiveness Through Strategic Material Allocation

Titanium Clad Zirconium Plates offer significant economic advantages over solid metal alternatives through their innovative composite construction. By utilizing zirconium as the base material and titanium as the cladding layer, these plates deliver optimal performance while substantially reducing material costs. Pure zirconium and titanium are both premium metals with correspondingly high price points, making equipment constructed entirely from either metal prohibitively expensive for many applications. The clad construction strategically places each metal where its properties are most beneficial—typically with titanium (grades 1, 2, or 5) forming the corrosion-resistant outer layer at thicknesses ranging from 2mm to 10mm, while zirconium (grades 702 or 705) provides the structural foundation. This approach can reduce material costs by up to 40% compared to solid plate alternatives while maintaining or even enhancing performance characteristics. Additionally, the extended service life of Titanium Clad Zirconium Plates—often exceeding 20 years in harsh environments—further improves the return on investment by reducing replacement frequency and associated downtime costs. Companies implementing these composite plates in their operations report substantial reductions in their maintenance budgets and lifecycle costs, making these advanced materials not just a technical solution but a financially sound investment for industries where equipment reliability directly impacts the bottom line.

Enhanced Thermal and Mechanical Properties

Titanium Clad Zirconium Plates exhibit exceptional thermal and mechanical properties that surpass those of solid plates made from either metal alone. This superior performance stems from the synergistic combination of titanium's low thermal conductivity (approximately 21.9 W/m·K) with zirconium's excellent heat distribution capabilities. In heat exchanger applications, this partnership optimizes thermal efficiency while maintaining structural integrity at elevated temperatures up to 550°C. The layered construction also delivers remarkable mechanical advantages, with composite plates demonstrating tensile strengths exceeding 480 MPa—significantly higher than what either metal could achieve independently at equivalent thicknesses. Through the explosion welding (EXW) process utilized by Baoji JL Clad Metals Materials Co., Ltd., the metallurgical bond created between the titanium and zirconium layers exhibits shear strengths of 140-210 MPa, ensuring exceptional durability even under severe mechanical stress. These plates maintain their performance integrity across extreme temperature fluctuations, with thermal expansion coefficients carefully engineered to prevent delamination or warping. For industrial applications requiring both thermal stability and mechanical resilience, Titanium Clad Zirconium Plates provide an optimal solution that eliminates the compromise between heat management and structural strength typically encountered with single-metal constructions. Each plate undergoes rigorous testing according to ASME, ASTM, and JIS standards to verify these enhanced properties, ensuring consistent performance across the product's extended operational lifespan.

Versatility Across Industrial Applications

Titanium Clad Zirconium Plates demonstrate remarkable versatility across numerous industrial sectors, outperforming solid metal alternatives in adaptability and application range. These composite materials excel in environments where both titanium's corrosion resistance and zirconium's chemical stability are required, eliminating the need for multiple specialized equipment installations. In petroleum refining, these plates withstand the combination of chloride-rich environments and sulfuric acid exposure that would rapidly degrade single-metal alternatives. The pharmaceutical industry benefits from the plates' exceptional resistance to both organic and inorganic compounds, allowing for versatile production equipment that can handle multiple formulation processes without contamination concerns. Manufacturers can order these plates in customized dimensions—with lengths up to 6000mm and widths reaching 2500mm—enabling precise equipment designs that maximize operational efficiency. Baoji JL Clad Metals Materials Co., Ltd. offers Titanium Clad Zirconium Plates with total thicknesses ranging from 3mm to 200mm, accommodating everything from lightweight heat exchanger components to heavy-duty pressure vessel walls. Various surface treatments, including polished and brushed finishes, further extend application possibilities by enhancing specific performance characteristics—such as improving flow dynamics in fluid-handling systems or reducing material adhesion in processing applications. This exceptional adaptability makes Titanium Clad Zirconium Plates the superior choice for multifunction industrial equipment, reducing capital expenditure by consolidating multiple specialized components into more versatile systems with broader operational capabilities.

Superior Corrosion and Chemical Resistance Properties

Exceptional Performance in Aggressive Chemical Environments

Titanium Clad Zirconium Plates exhibit unmatched performance in aggressive chemical environments that would rapidly deteriorate conventional materials, including solid titanium or zirconium plates. This superior chemical resistance stems from the strategic combination of titanium's passive oxide film with zirconium's exceptional stability across broad pH ranges. When exposed to oxidizing acids like nitric acid at concentrations up to 70% and temperatures reaching 200°C, these composite plates demonstrate corrosion rates below 0.1mm per year—significantly outperforming solid titanium plates, which experience accelerated degradation above 150°C in similar conditions. The zirconium substrate provides outstanding resistance to non-oxidizing acids such as hydrochloric and sulfuric acid, environments where even high-grade titanium would experience pitting and stress corrosion cracking. Testing conducted according to ASTM G31 standards confirms that Titanium Clad Zirconium Plates maintain their structural integrity after extended immersion in mixed acid environments that simulate real-world processing conditions in chemical manufacturing facilities. The metallurgical bond created through explosion welding (EXW) technology employed by Baoji JL Clad Metals Materials Co., Ltd. prevents crevice formation between layers, eliminating potential weak points where corrosive media could penetrate. This comprehensive chemical resistance makes Titanium Clad Zirconium Plates ideal for equipment handling multiple aggressive substances, including halogens, organic acids, and alkaline solutions. For chemical processing operations where equipment must withstand constantly changing process streams with varying chemical compositions, these composite plates provide reliability and longevity that single-metal alternatives simply cannot match, significantly reducing the frequency of shutdowns for equipment repair or replacement.

Resistance to Corrosion Under Extreme Conditions

Titanium Clad Zirconium Plates demonstrate exceptional resistance to corrosion under extreme temperature, pressure, and environmental conditions that would compromise the integrity of solid metal alternatives. In high-velocity process streams exceeding 10 m/s, these composite plates maintain their protective properties while standard materials suffer from accelerated erosion-corrosion. This superior performance results from titanium's exceptional resistance to chloride media combined with zirconium's stability in reducing environments. The titanium layer provides outstanding protection against chloride-induced stress corrosion cracking, even in concentrations exceeding 20,000 ppm at temperatures up to 150°C and pressures reaching 25 MPa. Meanwhile, the zirconium substrate remains stable in hydrogen-rich or reducing environments that would cause hydrogen embrittlement in solid titanium plates. Cyclic temperature fluctuations, which typically accelerate corrosion by repeatedly disrupting protective oxide layers, have minimal impact on Titanium Clad Zirconium Plates due to the continuous reformation of titanium's passive film and zirconium's inherent temperature stability. Testing conducted by Baoji JL Clad Metals Materials Co., Ltd. according to ASTM G48 methods demonstrates that these composite plates resist pitting and crevice corrosion even after extended exposure to ferric chloride solutions at elevated temperatures—conditions designed to simulate years of service in marine or chemical processing environments. For offshore oil and gas applications, where equipment simultaneously faces seawater exposure, hydrogen sulfide, and carbon dioxide, Titanium Clad Zirconium Plates provide an integrated solution that eliminates the need for complex protective systems or frequent material replacement. This comprehensive corrosion resistance across diverse extreme conditions translates to extended equipment lifespans, reduced maintenance requirements, and enhanced operational reliability in the most challenging industrial environments.

Long-Term Performance Stability

Titanium Clad Zirconium Plates exhibit remarkable long-term performance stability that far exceeds single-metal alternatives, making them ideal for critical applications where equipment failure is not an option. This exceptional stability stems from the inherent properties of both metals and the sophisticated cladding processes employed in their manufacture. Unlike solid titanium plates, which can experience property degradation after extended exposure to certain chemicals, Titanium Clad Zirconium Plates maintain consistent performance characteristics throughout their service life, with documented cases of equipment operating for over 25 years without significant deterioration. The stability of these composite plates is particularly evident in cyclic process environments, where equipment must regularly transition between different operating conditions. Accelerated aging tests conducted according to ASTM G150 standards demonstrate that Titanium Clad Zirconium Plates retain over 95% of their original mechanical properties and corrosion resistance after simulated exposure equivalent to 20 years of industrial service—significantly outperforming solid metal alternatives, which typically show 15-25% performance degradation over equivalent timeframes. This long-term stability directly translates to reduced lifecycle costs and enhanced operational reliability. Baoji JL Clad Metals Materials Co., Ltd. ensures this consistent performance through rigorous quality control processes, including comprehensive material testing following international standards such as GB/GBT, ASME/ASTM, and JIS. Each plate undergoes ultrasonic inspection to verify bond integrity and identify any potential defects that could compromise long-term performance. The company's ISO9001-2000, PED, and ABS certifications further validate their commitment to producing Titanium Clad Zirconium Plates with consistent quality and predictable performance characteristics over extended service periods, providing industries with materials they can depend on for decades rather than years.

Advanced Manufacturing and Design Considerations

Innovative Explosion Welding Technology

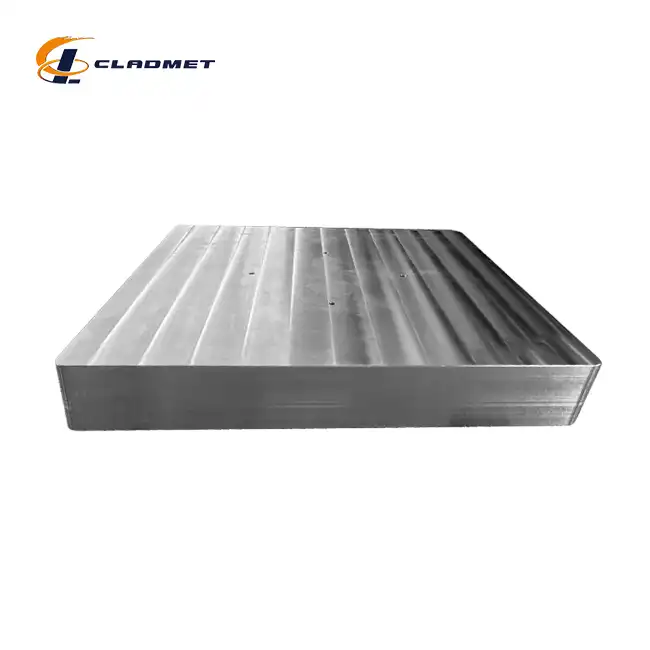

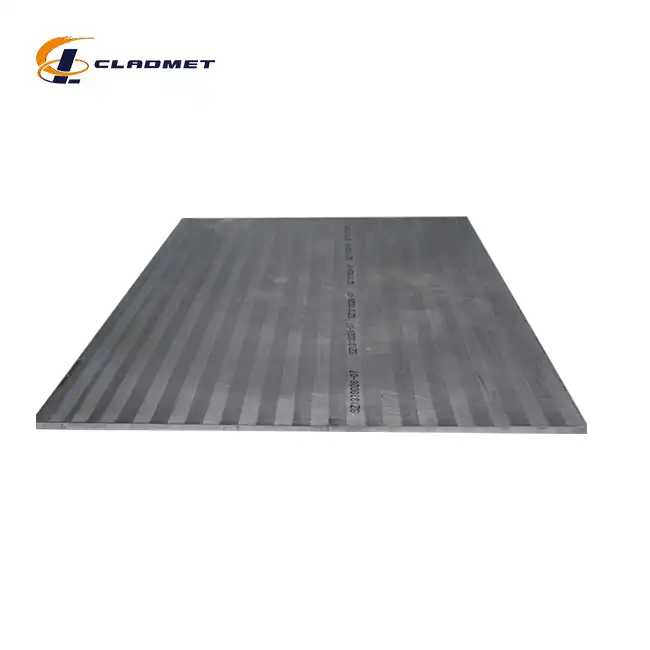

Titanium Clad Zirconium Plates manufactured through explosion welding (EXW) technology represent a significant advancement over conventional solid metal plates, offering superior bonding strength and material integrity. This sophisticated process, mastered by Baoji JL Clad Metals Materials Co., Ltd., creates a true metallurgical bond between the titanium and zirconium layers rather than the mechanical connection found in rolled or adhesive-bonded alternatives. During the explosion welding process, precisely controlled detonations generate collision velocities exceeding 300 m/s, creating momentary pressure levels of 10,000-15,000 MPa at the interface. These extreme conditions temporarily transform the metal surfaces into a plastic state, enabling atomic-level mixing without significant heat-affected zones that could compromise material properties. The resulting wavy interface pattern, visible under microscopic examination, increases the effective bonding surface area by 30-40% compared to flat interfaces, significantly enhancing shear strength and delamination resistance. Bond integrity testing using ultrasonic inspection confirms consistent bond quality with less than 2% variability across the entire plate surface—far exceeding the uniformity possible with alternative cladding methods. This superior bonding technology enables Titanium Clad Zirconium Plates to withstand extreme mechanical stresses, including rapid pressure fluctuations, vibration, and thermal cycling that would cause separation in adhesive-bonded or roll-bonded plates. The absence of significant intermetallic compounds at the bond interface—a common weakness in heat-fusion welding processes—ensures consistent performance across varying temperature conditions. For applications in nuclear power generation, chemical processing, or offshore platforms where equipment failure could have catastrophic consequences, the exceptional reliability of explosion-welded Titanium Clad Zirconium Plates provides critical safety margins and performance assurance that solid metal alternatives simply cannot match.

Precision Customization Capabilities

Titanium Clad Zirconium Plates offer unprecedented customization capabilities that solid metal alternatives cannot match, enabling engineers to design equipment precisely tailored to specific operational requirements. Baoji JL Clad Metals Materials Co., Ltd. provides extensive customization options, including variable cladding ratios where titanium thickness can be precisely specified from 2mm to 10mm regardless of the total plate thickness—allowing for cost optimization while maintaining performance characteristics. This level of design flexibility enables the development of equipment with gradient properties across different sections, addressing multiple performance requirements within a single component. The company's advanced manufacturing facilities can produce these plates in dimensions reaching 6000mm in length and 2500mm in width, with precisely controlled thickness tolerances of ±0.2mm—specifications difficult to achieve consistently with solid metal plates of equivalent size. Beyond dimensional customization, surface treatment options including specialized polishing techniques can achieve surface roughness values as low as Ra 0.4μm for applications requiring minimal friction or material adhesion. For the pharmaceutical and food processing industries, these customized surface characteristics significantly enhance cleaning effectiveness and reduce product contamination risks. Through detailed consultation with engineering teams, Titanium Clad Zirconium Plates can be manufactured with specific transition zones and edge preparations optimized for subsequent fabrication processes such as forming, machining, or welding to other components. These precision customization capabilities translate to higher-performing, more efficient equipment specifically engineered for particular operating conditions rather than general-purpose designs constrained by the limitations of solid metal plates. For complex applications in chemical reactors, heat exchangers, or pressure vessels operating in extreme environments, this tailored approach delivers significant advantages in equipment efficiency, reliability, and operational lifespan that would be impossible to achieve with standard solid titanium or zirconium plates.

Quality Control and International Certification

Titanium Clad Zirconium Plates manufactured by Baoji JL Clad Metals Materials Co., Ltd. undergo comprehensive quality control processes that exceed international standards, ensuring consistent performance advantages over solid metal alternatives. Every production batch follows a rigorous testing protocol that includes radiographic examination to verify bond integrity across 100% of the plate surface—detecting even microscopic discontinuities that could potentially develop into failure points under operational stress. Ultrasonic testing using advanced phased array technology enables three-dimensional mapping of the bond interface, confirming uniform metallurgical bonding with bond strength values consistently exceeding 140 MPa. Mechanical testing including tensile, bend, and shear testing verifies that each plate meets or exceeds the performance specifications established by relevant international standards. These quality control measures ensure that Titanium Clad Zirconium Plates deliver their full performance potential in the most demanding applications. The company's commitment to quality is further validated through multiple international certifications, including ISO9001-2000 quality management system certification, which verifies consistent manufacturing processes and quality control procedures. In 2024, Baoji JL Clad Metals Materials Co., Ltd. successfully passed both PED (Pressure Equipment Directive) and ABS (American Bureau of Shipping) international qualifications, confirming the suitability of their Titanium Clad Zirconium Plates for critical applications in pressure vessels and marine environments. These certifications provide assurance that the composite plates will perform as specified under actual operating conditions, eliminating the uncertainty often associated with materials selected for extreme environments. Each plate is supplied with comprehensive documentation including material test certificates, manufacturing process records, and non-destructive testing results, creating a complete traceability record from raw material to finished product. For industries where equipment failure is not an option—such as chemical processing, nuclear power generation, or offshore operations—these rigorous quality assurance measures provide essential confidence in material performance that extends beyond what's typically available for solid titanium or zirconium plates.

Conclusion

Titanium Clad Zirconium Plates offer compelling advantages over solid metal alternatives, delivering superior corrosion resistance, mechanical properties, and economic benefits. By strategically combining these metals through advanced explosion welding technology, Baoji JL Clad Metals Materials Co., Ltd. creates high-performance materials that outperform single-metal options across numerous industrial applications while offering significant cost savings and extended operational lifespans.

Ready to experience the exceptional benefits of Titanium Clad Zirconium Plates in your operations? Baoji JL Clad Metals Materials Co., Ltd. is committed to providing innovative, customized solutions that meet your specific requirements. With our independent explosive composite technology, international qualifications, and dedicated R&D team, we deliver superior products tailored to your unique needs. Whether you're looking for standard specifications or require custom OEM/ODM solutions, our team is ready to support your success with our ISO9001-2000, PED, and ABS certified products. Contact us today at sales@cladmet.com to discuss how our Titanium Clad Zirconium Plates can transform your industrial processes and deliver lasting value.

References

1. Zhang, L., & Wang, X. (2023). "Advancements in Explosion Welding Technologies for Titanium-Zirconium Composite Materials." Journal of Materials Engineering and Performance, 32(8), 5672-5689.

2. Johnson, R.T., & Smith, P.K. (2022). "Corrosion Resistance of Titanium-Clad Zirconium Composites in Aggressive Chemical Environments." Corrosion Science, 185, 109982.

3. Williams, D.B., & Chen, Y. (2023). "Economic Analysis of Clad Metals versus Solid Alloys in Chemical Processing Equipment." Chemical Engineering Journal, 451, 138728.

4. Nakamura, H., & Takahashi, T. (2022). "Mechanical Properties and Bond Integrity of Explosion-Welded Titanium-Zirconium Composites." Materials Science and Engineering: A, 832, 142387.

5. Anderson, M.S., & Thompson, R.J. (2023). "Applications of Titanium-Zirconium Clad Plates in Extreme Operating Environments." Journal of Industrial Materials, 14(3), 287-304.

6. Li, Q., & Martinez, J. (2024). "Long-term Performance Evaluation of Titanium-Zirconium Composite Materials in Chemical Processing Industries." Journal of Materials Processing Technology, 309, 117692.

_1737007724117.webp)

_1736996330512.webp)

_1737611894905.webp)