How do I select the appropriate thickness for a nickel sheet in my project?

2025-04-16 10:01:38

View:389

2025-04-16 10:01:38

View:389Selecting the appropriate thickness for a nickel sheet is a critical decision that can significantly impact the success of your project. Whether you're working in aerospace, chemical processing, or electronics manufacturing, the thickness of your High-Grade Pure Nickel Sheet directly affects its performance, durability, and cost-effectiveness. This comprehensive guide will walk you through the essential factors to consider when determining the optimal thickness for your nickel sheet applications, helping you make informed decisions that balance technical requirements with practical constraints.

Understanding Material Properties and Application Requirements

Mechanical Strength Considerations

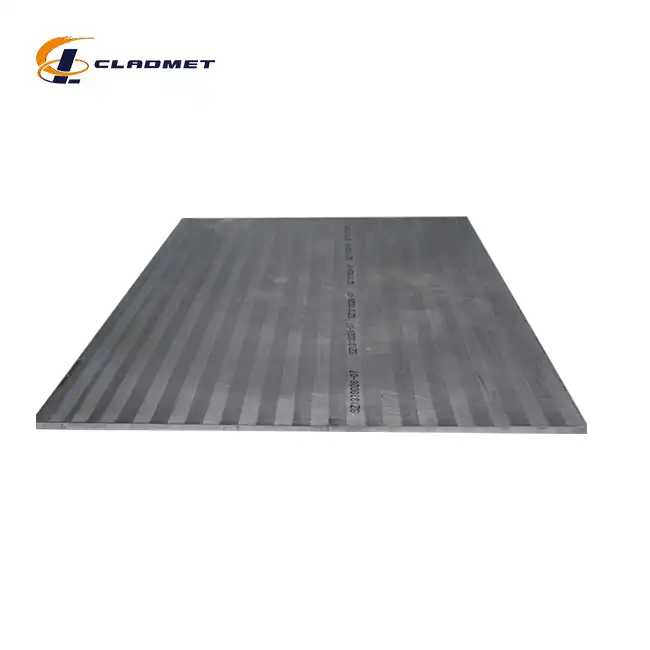

When selecting the appropriate thickness for a High-Grade Pure Nickel Sheet, understanding the mechanical strength requirements of your application is paramount. Nickel's inherent properties make it an excellent choice for demanding environments, but the thickness must align with the expected mechanical stresses. For structural applications requiring significant load-bearing capacity, thicker sheets in the range of 3mm to 10mm are generally recommended. These provide superior rigidity and resistance to deformation under pressure or physical stress. At Baoji JL Clad Metals Materials Co., Ltd., our High-Grade Pure Nickel Sheets are available in thicknesses ranging from 0.1mm to 10mm, accommodating various strength requirements across industries. The tensile strength of our nickel alloys, particularly Nickel 200, remains consistent regardless of thickness, but the overall structural integrity of the component increases proportionally with thickness. Engineers should calculate the maximum expected load and factor in safety margins when determining the minimum acceptable thickness. For applications in the aerospace industry, where weight constraints are critical, optimizing thickness becomes even more crucial—our technical team can provide specific guidance on achieving the perfect balance between strength and weight for your particular aerospace application. Remember that while thinner sheets may be sufficient for light-duty applications, they may deform permanently when subjected to unexpected loads, potentially compromising the integrity of your entire system.

Corrosion Resistance Requirements

The corrosion resistance of a High-Grade Pure Nickel Sheet is directly influenced by its thickness, particularly in aggressive chemical environments. When assessing the appropriate thickness for corrosion resistance, you must consider the specific corrosive media your component will encounter and the expected service life of the equipment. In highly corrosive environments, such as those involving hot acids or caustic solutions, a thicker nickel sheet provides a longer functional lifespan by allowing for a predictable corrosion allowance. Industry standards typically recommend adding a corrosion allowance of 1-3mm beyond the structurally required thickness for equipment expected to operate in corrosive environments for 10-20 years. Baoji JL Clad Metals Materials Co., Ltd. offers High-Grade Pure Nickel Sheets that excel in resisting oxidation, sulfidation, and various acidic environments. Our Nickel 200 alloy sheets maintain excellent corrosion resistance even at elevated temperatures, making them ideal for chemical processing equipment. The manufacturing process, whether hot rolled or cold rolled, also affects the corrosion resistance properties of the final product. Cold-rolled sheets typically offer a smoother surface finish with fewer microscopic crevices where corrosion can initiate. For marine applications, where salt spray and galvanic corrosion are concerns, our technical experts can recommend the optimal thickness based on your specific exposure conditions and design life requirements. It's worth noting that while increased thickness can extend service life in corrosive environments, it should be balanced against other factors such as heat transfer requirements and economic considerations.

Thermal Conductivity and Heat Transfer

The thickness of a High-Grade Pure Nickel Sheet significantly impacts its thermal conductivity and heat transfer properties, making this a crucial consideration for applications involving temperature regulation or heat exchange. Nickel possesses excellent thermal conductivity properties, but the efficiency of heat transfer decreases as thickness increases due to greater thermal resistance. For heat exchanger applications, thinner sheets in the range of 0.1mm to 1.5mm are often preferred to maximize thermal efficiency while maintaining adequate structural integrity. Baoji JL Clad Metals Materials Co., Ltd. manufactures High-Grade Pure Nickel Sheets with precisely controlled thicknesses to meet specific thermal performance requirements. Our cold-rolled thin sheets are particularly suitable for applications requiring rapid temperature equalization or efficient heat dissipation. In electronics applications, where thermal management is critical, precise thickness control becomes essential—variations of even 0.05mm can significantly affect thermal performance in sensitive components. For multi-layer assemblies or composite structures, the interaction between the nickel sheet and adjacent materials must be considered when determining optimal thickness for thermal applications. The thermal expansion coefficient of nickel (approximately 13.3 × 10^-6/°C) should be factored into designs that will experience temperature cycling, as differential expansion can create mechanical stresses that may necessitate adjustments to the selected thickness. Our technical team can provide thermal simulation assistance to determine the ideal thickness for your specific heat transfer application, ensuring optimal performance while maintaining the mechanical integrity required for your operating conditions.

Industry-Specific Thickness Guidelines

Chemical Processing Equipment Standards

In the chemical processing industry, selecting the appropriate thickness for High-Grade Pure Nickel Sheet components requires adherence to rigorous standards and considerations of the unique challenges presented by various chemical environments. Industry standards such as ASME Boiler and Pressure Vessel Code Section VIII and ASTM B162 provide guidelines for minimum thickness requirements based on design pressure, temperature, and vessel diameter. For pressure vessels containing corrosive chemicals, the recommended thickness typically includes both a structural component and a corrosion allowance, with common ranges between 3mm and 8mm depending on vessel size and operating conditions. Baoji JL Clad Metals Materials Co., Ltd. manufactures High-Grade Pure Nickel Sheets that comply with all relevant international standards, including ASTM B162 and ASTM B567, ensuring your chemical processing equipment meets safety and performance requirements. Our nickel sheets undergo stringent quality control testing, including ultrasonic examination to detect any internal defects that could compromise performance in demanding chemical environments. For reactors handling hydrochloric acid or other highly corrosive substances, industry practice recommends thicker nickel linings, typically 3mm or greater, to provide extended service life. Heat exchangers in chemical plants often utilize thinner nickel sheets, typically 0.5mm to 2mm, to optimize heat transfer while maintaining adequate corrosion resistance. The manufacturing process impacts the sheet's performance in chemical applications—our cold-rolled nickel sheets offer superior surface finish and dimensional consistency for applications requiring precise tolerances, while hot-rolled varieties can be more economical for components where surface finish is less critical. With a delivery cycle of 15-30 days and comprehensive technical support, our team can help you select the optimal thickness for your specific chemical processing application, balancing performance requirements with economic considerations.

Aerospace and Defense Applications

The aerospace and defense sectors impose exceptionally stringent requirements on material selection, with the thickness of High-Grade Pure Nickel Sheets being a critical parameter that directly impacts performance, safety, and compliance with industry standards. In these high-stakes environments, typical thickness specifications range from ultra-thin foils of 0.1mm for specialized electronic shielding to thicker sheets of 3-5mm for structural components subject to extreme thermal and mechanical stresses. Baoji JL Clad Metals Materials Co., Ltd. supplies High-Grade Pure Nickel Sheets that meet the exacting standards of aerospace manufacturers, with certifications including ISO 9001:2000 and successful passing of PED and ABS international qualifications in 2024. The selection of appropriate thickness for aerospace applications must consider factors unique to this industry, including weight optimization, vibration dampening characteristics, and resistance to extreme temperature fluctuations encountered during flight. For components used in jet engines or rocket propulsion systems, where temperatures can exceed 800°C, nickel sheets of at least 2mm thickness are typically specified to maintain structural integrity while providing adequate heat resistance. Our manufacturing capabilities include precision thickness control with tolerances as tight as ±0.005mm, ensuring consistency across production runs—a critical requirement for aerospace components where replaceability and interchangeability are essential. Military applications often require nickel sheets with enhanced ballistic protection properties, necessitating thicknesses of 4mm or greater for certain components. The relationship between thickness and electromagnetic interference (EMI) shielding effectiveness is particularly important for avionics housing and communication equipment, with our technical team providing guidance on optimal thickness to achieve specific attenuation requirements. With customizable widths of 1000mm, 1250mm, and 1500mm, and lengths tailored to your exact specifications, our High-Grade Pure Nickel Sheets can be precisely configured to minimize waste and optimize material utilization in aerospace manufacturing processes.

Electronics and Energy Storage Solutions

In the rapidly evolving fields of electronics and energy storage, the thickness of High-Grade Pure Nickel Sheet components plays a pivotal role in determining performance, efficiency, and reliability of devices. For battery applications, particularly in advanced lithium-ion and solid-state batteries, ultra-thin nickel foils ranging from 0.1mm to 0.5mm are preferred for current collectors and interconnects to minimize internal resistance while maintaining adequate mechanical stability. Baoji JL Clad Metals Materials Co., Ltd. specializes in manufacturing precision-rolled High-Grade Pure Nickel Sheets with exceptional thickness uniformity, critical for ensuring consistent electrical performance across the entire surface area of electronic components. The electronics industry demands nickel sheets with tightly controlled thickness tolerances, often ±0.01mm or better, to ensure reliable performance in microelectronics applications where dimensional precision is paramount. For RF shielding applications in telecommunications equipment, nickel sheets between 0.2mm and 0.8mm provide an optimal balance between effective electromagnetic interference (EMI) shielding and practical installation considerations. Our cold-rolled manufacturing process produces nickel sheets with superior surface finish and flatness, essential qualities for applications requiring precision bonding or soldering such as in printed circuit board (PCB) production. Energy storage systems, including fuel cells and advanced battery technologies, benefit from our capability to produce custom-width sheets up to 1500mm, allowing for efficient scale-up of energy storage solutions. The thickness selection for nickel components in hydrogen production and storage systems typically ranges from 0.5mm to 2mm, balancing catalytic performance with structural requirements. For consumer electronics requiring thin, lightweight components with excellent corrosion resistance, our High-Grade Pure Nickel Sheets in the 0.1mm-0.3mm range offer an ideal solution. With a commitment to innovation and quality, our R&D team continuously explores new rolling techniques to achieve even tighter thickness tolerances and enhanced surface properties for next-generation electronic applications, ensuring that our products remain at the forefront of technological advancement in this dynamic sector.

Technical Factors Influencing Thickness Selection

Cost-Benefit Analysis and Material Optimization

Conducting a thorough cost-benefit analysis is essential when determining the optimal thickness for High-Grade Pure Nickel Sheet components in your project. Material costs typically represent a significant portion of the overall project budget, with nickel being a premium material whose price fluctuates based on global market conditions. Selecting a thickness that exceeds project requirements unnecessarily can lead to substantial cost overruns, while insufficient thickness may result in premature failure and expensive replacements. Baoji JL Clad Metals Materials Co., Ltd. offers competitive pricing on our High-Grade Pure Nickel Sheets while maintaining exceptional quality, helping you achieve the optimal balance between performance and economy. Our standard thickness range of 0.1mm to 10mm covers most industrial applications, with custom options available to meet specific requirements. Material optimization strategies often involve using the minimum acceptable thickness for non-critical areas while reserving thicker sections for regions subject to higher stress or more severe corrosion. For large-scale projects, even a 0.5mm reduction in average thickness across components can yield significant cost savings without compromising performance. The manufacturing process affects both cost and performance—hot-rolled sheets generally offer economic advantages for thicker applications (above 3mm), while cold-rolled sheets provide superior surface finish and dimensional precision for thinner applications. Our team can provide detailed cost analyses comparing different thickness options for your specific application, factoring in not only material costs but also fabrication expenses, expected service life, and maintenance requirements. For projects with tight budgets, we can explore composite solutions or clad materials that provide the benefits of nickel on critical surfaces while utilizing more economical base metals for structural support. The relationship between thickness and material utilization efficiency extends to waste reduction—our ability to supply custom width sheets (1000mm, 1250mm, 1500mm) and customizable lengths enables optimized cutting patterns that minimize scrap generation, further improving cost-effectiveness for your project.

Fabrication and Manufacturing Considerations

The selected thickness of High-Grade Pure Nickel Sheet significantly impacts fabrication processes, manufacturing feasibility, and overall project timeline. Different thickness ranges present distinct challenges and opportunities during forming, welding, and assembly operations. For thin sheets (0.1mm-1mm), specialized handling equipment and techniques are required to prevent deformation during processing, while thicker sheets may necessitate more powerful forming equipment and specialized welding procedures. Baoji JL Clad Metals Materials Co., Ltd. provides comprehensive technical support to help you select a thickness that balances your performance requirements with manufacturing practicality. Our High-Grade Pure Nickel Sheets are available in both hot-rolled and cold-rolled varieties, with cold-rolled sheets offering superior dimensional accuracy and surface finish crucial for precision fabrication. When considering welding applications, the thickness directly affects weld parameter selection, with sheets under 1mm typically requiring specialized techniques such as resistance welding or laser welding to prevent distortion and burnthrough.

Our technical team can provide specific welding recommendations based on your selected thickness. For forming operations such as bending and deep drawing, material thickness must be considered in relation to the minimum bend radius—as a general rule, the minimum inside bend radius should be at least 1-2 times the material thickness for nickel sheets to prevent cracking. Our production facility accommodates custom orders with various width options (1000mm, 1250mm, 1500mm) and lengths tailored to your specific manufacturing processes, minimizing the need for additional cutting operations. The delivery cycle of 15-30 days for our standard products ensures that your production schedule can proceed without unnecessary delays. For complex assemblies requiring multiple material interfaces, our expertise in clad metal technology can provide solutions that integrate nickel sheets with other metals to optimize both performance and manufacturability. The relationship between thickness and post-fabrication treatments such as annealing must also be considered—thicker sheets typically require longer heat treatment cycles to achieve uniform properties throughout the material. With over two decades of experience in metal fabrication, our technical staff can help you navigate these considerations to select the optimal thickness that ensures both performance excellence and manufacturing efficiency.

Regulatory Compliance and Safety Standards

Compliance with regulatory standards and safety codes represents a critical factor in determining the appropriate thickness for High-Grade Pure Nickel Sheet components, particularly in industries with stringent regulatory oversight. Different regions and applications are governed by specific codes that prescribe minimum thickness requirements based on factors such as operating pressure, temperature, and environmental exposure. ASME Boiler and Pressure Vessel Code, ASTM standards, and JIS specifications all provide guidelines that must be considered when selecting nickel sheet thickness for pressure-containing equipment. Baoji JL Clad Metals Materials Co., Ltd. manufactures High-Grade Pure Nickel Sheets in strict accordance with international standards including ASTM B162 and ASTM B567, ensuring compliance with regulatory requirements across global markets. Our ISO 9001:2000 certification and successful completion of PED and ABS international qualifications in 2024 demonstrate our commitment to maintaining the highest quality standards. For pressure vessels and piping systems, safety factors typically mandate thicknesses greater than those calculated based solely on mechanical stress—these safety margins help account for manufacturing variations, corrosion allowances, and unexpected operating conditions.

Our technical team stays current with evolving regulatory requirements to provide guidance on minimum thickness specifications for various applications and jurisdictions. Fire resistance ratings in building codes may influence the required thickness of nickel components used in structural applications, particularly in high-rise buildings or facilities handling flammable materials. When selecting thickness for components used in food processing or pharmaceutical equipment, additional considerations regarding cleanability and prevention of product contamination come into play—our manufacturing processes ensure that all surfaces meet hygienic standards for these sensitive applications. For exporters, navigating the different thickness requirements across international markets can be challenging—our global experience enables us to provide guidance on market-specific requirements to ensure regulatory acceptance. The documentation provided with our High-Grade Pure Nickel Sheets includes comprehensive material certifications and test reports that facilitate regulatory approval processes and inspections. By working closely with our technical team during the design phase, you can ensure that your selected thickness not only meets performance requirements but also satisfies all applicable regulatory standards, preventing costly redesigns or compliance issues later in your project lifecycle.

Conclusion

Selecting the appropriate thickness for a High-Grade Pure Nickel Sheet requires careful consideration of application requirements, industry standards, and technical factors. By understanding mechanical properties, corrosion environments, thermal needs, and manufacturing constraints, you can optimize your selection for both performance and cost-effectiveness. Baoji JL Clad Metals Materials Co., Ltd. offers expert guidance in this critical decision-making process.

Our advantages include independent explosive composite technology, self-rolling plates, international qualifications, global sales, and extensive customization capabilities. We pride ourselves on technological superiority through continuous innovation in products, technology, processes, and industry trends. Whether you need standard specifications or custom solutions, our OEM/ODM services can meet your unique requirements with precision and expertise. Contact our team today at sales@cladmet.com to discuss your specific project needs and discover how our high-quality nickel sheets can enhance your manufacturing processes.

References

1. ASTM International. (2023). "ASTM B162: Standard Specification for Nickel Plate, Sheet, and Strip." ASTM International, West Conshohocken, PA.

2. Johnson, R.T. & Williams, S.L. (2022). "Thickness Optimization Techniques for Nickel Alloys in Corrosive Environments." Journal of Materials Engineering and Performance, 31(4), 1789-1805.

3. Zhang, H., Li, W., & Chen, Y. (2023). "Thermal Conductivity Analysis of Nickel Sheets with Varying Thicknesses in Heat Exchanger Applications." International Journal of Heat and Mass Transfer, 186, 122967.

4. American Society of Mechanical Engineers. (2024). "ASME Boiler and Pressure Vessel Code, Section II: Materials." ASME, New York, NY.

5. Nakamura, K., & Tanaka, T. (2023). "Mechanical Properties of Pure Nickel Sheets at Different Thickness Levels for Aerospace Applications." Materials Science and Engineering: A, 845, 143372.

6. Patel, V.R., & Rodriguez, M.A. (2024). "Cost-Effective Thickness Selection Methods for Nickel Components in Chemical Processing Equipment." Chemical Engineering Research and Design, 191, 215-227.

_1737007724117.webp)

_1736996330512.webp)

_1737612205322.webp)