How are Titanium Clad Aluminum Plates Manufactured?

2025-04-24 09:44:55

View:389

2025-04-24 09:44:55

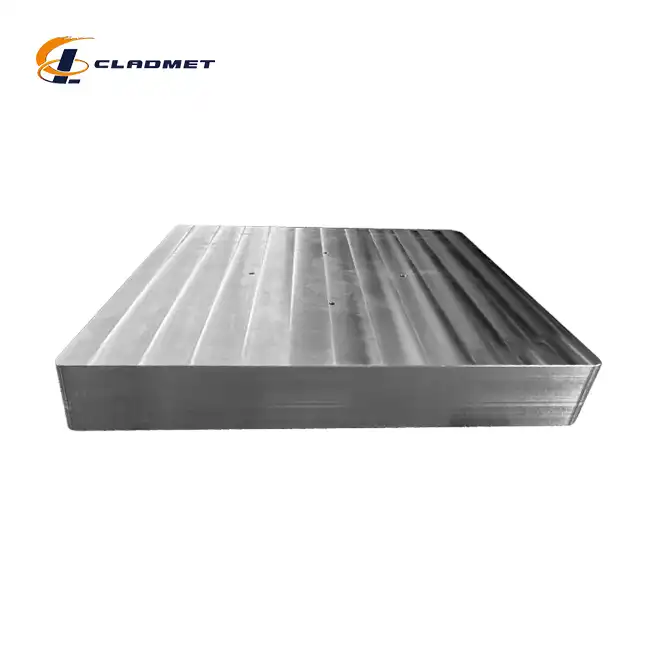

View:389Titanium Clad Aluminum Plates represent a sophisticated engineering solution that combines the exceptional properties of both titanium and aluminum into a single, high-performance material. These composite plates are manufactured through advanced bonding technologies that create a metallurgical bond between a titanium layer and an aluminum substrate. The manufacturing process involves precise preparation, controlled bonding methods, and rigorous quality control to ensure the final product delivers optimal performance across various demanding industrial applications. This article explores the intricate manufacturing processes, technical considerations, and practical applications of Titanium Clad Aluminum Plates, highlighting why they've become increasingly essential in industries requiring materials with superior strength-to-weight ratios and exceptional corrosion resistance.

Manufacturing Processes of Titanium Clad Aluminum Plates

Explosive Bonding Technology

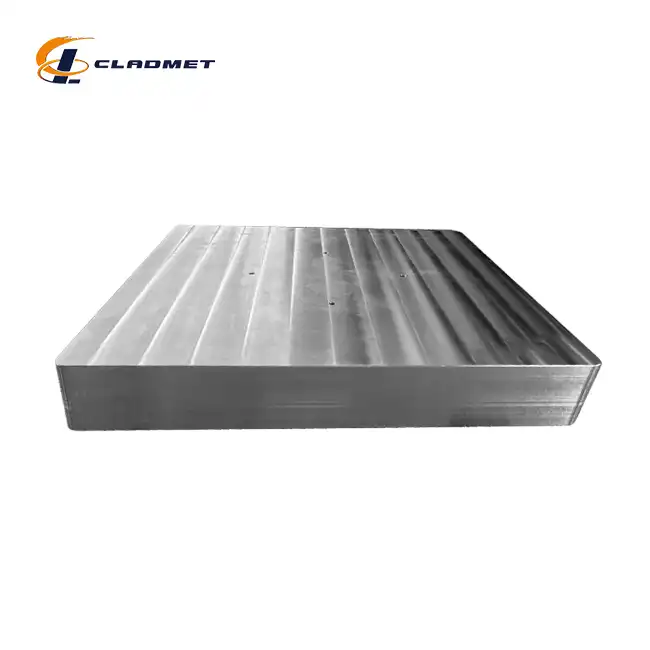

Explosive bonding represents one of the most effective methods for manufacturing Titanium Clad Aluminum Plates. This dynamic technique utilizes controlled detonation to create an exceptionally strong metallurgical bond between titanium and aluminum layers. The process begins with meticulous surface preparation of both metals to ensure optimal cleanliness and reactivity. The aluminum base plate is positioned horizontally while the titanium plate is placed above it at a precisely calculated angle, with explosive material carefully arranged on the upper surface. When detonated, the explosive generates an intense pressure wave that propels the titanium plate downward at extremely high velocity (typically 150-300 m/s). This collision creates momentary localized heating at the interface while generating sufficient pressure to form a wavy metallurgical bond at the atomic level. This waviness increases the surface area of the bond and creates mechanical interlocking in addition to the metallurgical bond. For Titanium Clad Aluminum Plates, this technique is particularly valuable as it allows joining of these dissimilar metals without excessive heat that might compromise their inherent properties or create brittle intermetallic compounds. The resulting bond typically achieves 95-100% of the theoretical strength possible between these materials, making explosive bonding the preferred method for applications requiring maximum integrity in Titanium Clad Aluminum Plates. Baoji JL Clad Metals Materials Co., Ltd. has perfected this technology through years of specialized experience, utilizing explosive bonding to create plates with cladding thicknesses ranging from 1mm to 20mm, with lengths reaching up to 12 meters and widths between 1000-2500mm.

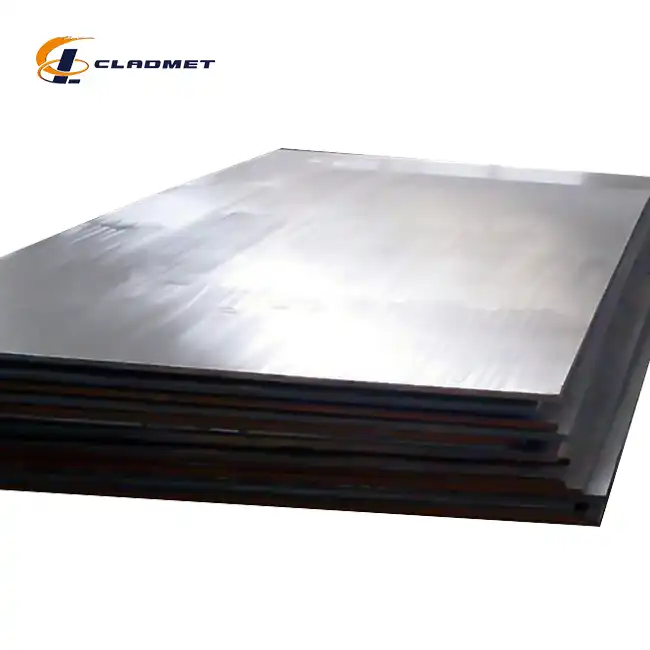

Roll Bonding Process

Roll bonding provides an alternative manufacturing approach for creating Titanium Clad Aluminum Plates, particularly suitable for thinner gauge materials and continuous production requirements. This process begins with rigorous surface preparation where both titanium and aluminum surfaces undergo degreasing, wire brushing, and chemical etching to remove oxides and contaminants that might inhibit bonding. The prepared materials are then stacked together and preheated to temperatures typically ranging from 300-500°C, which helps to soften the materials without reaching their melting points. The heated composite stack is then passed through a series of high-pressure rolling mills where extreme compressive forces (often exceeding 70% reduction in thickness) cause plastic deformation of both metals. This deformation breaks up surface oxides and brings fresh metal surfaces into intimate contact, allowing solid-state diffusion to occur at the interface. For Titanium Clad Aluminum Plates, careful temperature control is critical during this process to prevent the formation of brittle intermetallic compounds that could compromise bond integrity. Post-rolling heat treatment may be employed to enhance diffusion at the bond interface and relieve residual stresses. Baoji JL Clad Metals specializes in roll-bonded Titanium Clad Aluminum Plates designed for aerospace and chemical processing applications, offering superior surface finish and dimensional consistency. Their roll bonding technology enables the production of plates with precise cladding ratios and excellent thermal conductivity properties, with each plate undergoing comprehensive ultrasonic inspection to verify bond integrity across 100% of the surface area.

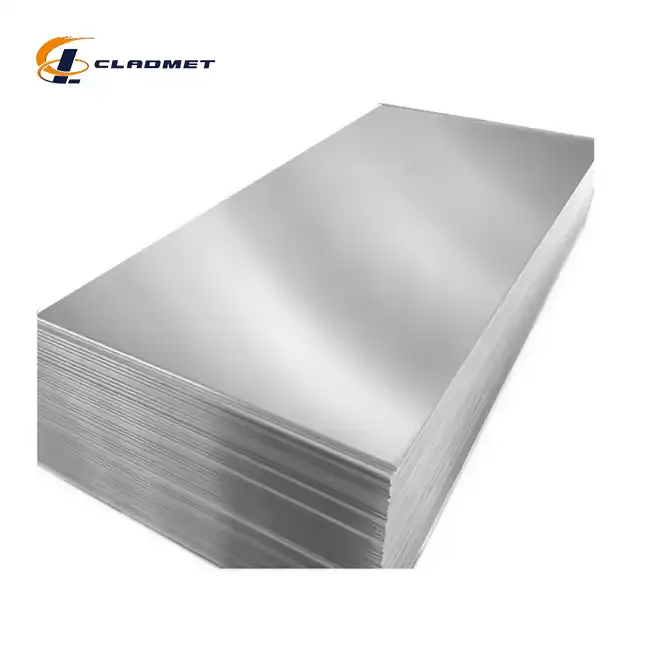

Diffusion Bonding Method

Diffusion bonding represents a sophisticated solid-state joining technique used to create premium-quality Titanium Clad Aluminum Plates where exceptional bond integrity and precise interface characteristics are required. This method relies on atomic diffusion across the material interface under carefully controlled conditions of elevated temperature and pressure. The process begins with ultra-precise surface preparation of both titanium and aluminum components, including polishing to mirror finishes and specialized cleaning protocols to remove even microscopic contaminants. The prepared metals are then stacked in the desired configuration and placed in a specialized vacuum hot press or hot isostatic pressing (HIP) chamber. Under vacuum conditions (typically 10^-5 torr or better), the assembly is heated to temperatures ranging from 500-600°C (below the melting point of aluminum) while simultaneously applying uniform pressure of 5-30 MPa across the entire surface for extended periods (often 2-24 hours). These conditions promote solid-state diffusion of atoms across the interface without bulk melting, creating an exceptionally clean and strong bond. For Titanium Clad Aluminum Plates, diffusion bonding creates a transition zone with controlled intermixing of elements, avoiding the thick brittle intermetallic compounds that can form in other processes. Baoji JL Clad Metals employs state-of-the-art diffusion bonding technology for their premium Titanium Clad Aluminum Plates used in critical applications such as semiconductor manufacturing equipment and aerospace components. Their diffusion-bonded plates feature exceptional thermal cycling resistance and precisely controlled interface characteristics, with each plate undergoing comprehensive metallographic examination and mechanical testing to ensure optimal performance under the most demanding service conditions.

Quality Control and Testing of Titanium Clad Aluminum Plates

Non-Destructive Testing Methodologies

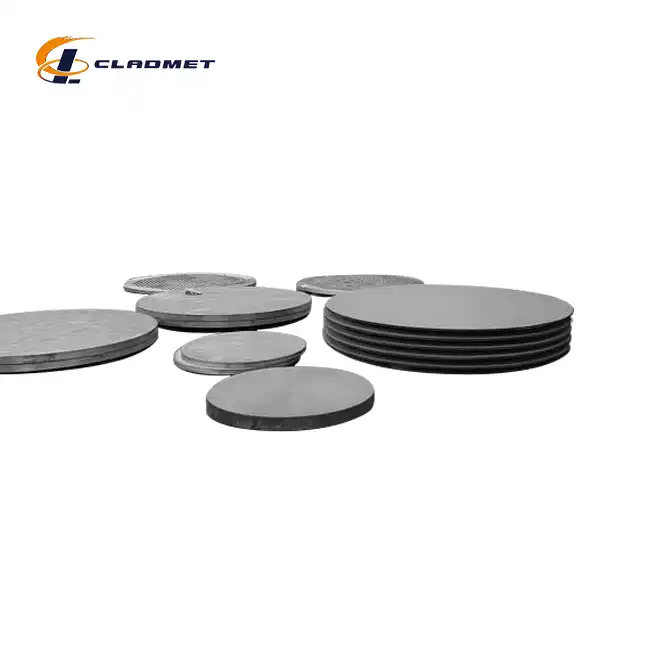

Non-destructive testing (NDT) plays a pivotal role in ensuring the exceptional quality and performance reliability of Titanium Clad Aluminum Plates. Ultrasonic testing stands as the primary NDT method, utilizing high-frequency sound waves to detect any subsurface discontinuities or bond imperfections that might compromise the structural integrity of these composite materials. During this procedure, technicians employ specialized transducers to transmit ultrasonic waves through the clad plate, analyzing the reflected signals for any anomalies that might indicate delamination, inclusions, or weak bonding areas. The C-scan mapping technique provides a comprehensive visual representation of the entire bonded interface, allowing quality control specialists to verify 100% bond integrity across the Titanium Clad Aluminum Plates. Radiographic testing offers another valuable perspective by using X-rays or gamma rays to detect internal defects, particularly beneficial for thicker plate configurations where ultrasonic penetration might be challenging. For surface integrity verification, dye penetrant testing and eddy current inspection methods reveal even microscopic surface defects that could potentially initiate corrosion or fatigue failures under service conditions. Baoji JL Clad Metals Materials Co., Ltd. implements a rigorous multi-stage NDT protocol for all their Titanium Clad Aluminum Plates, conforming strictly to international standards including ASTM E1001 for ultrasonic examination and ASTM E94 for radiographic testing. Their quality control laboratory features advanced phased array ultrasonic testing equipment capable of detecting bond imperfections as small as 6mm in diameter, ensuring that only plates with verified bond integrity of 99.5% or higher are cleared for shipment. This comprehensive NDT regime provides customers with confidence that the Titanium Clad Aluminum Plates will perform reliably even in the most demanding aerospace, chemical processing, or marine applications.

Mechanical Property Verification

Mechanical property verification constitutes a fundamental aspect of quality control for Titanium Clad Aluminum Plates, ensuring these composite materials meet or exceed the stringent performance requirements of their intended applications. Shear strength testing serves as the primary indicator of bond integrity, where specialized fixtures apply increasing lateral force to the cladding layer until failure occurs. For high-quality Titanium Clad Aluminum Plates, the bond should demonstrate shear strength values exceeding 140 MPa, with failure occurring within the aluminum substrate rather than at the bonded interface. Tensile testing of full-thickness specimens provides critical data on the composite's overall strength characteristics, while bend testing (typically performed at 180° over mandrels with diameters three times the plate thickness) verifies bond ductility and resistance to delamination under severe plastic deformation. Impact testing at various temperatures assesses the plate's toughness and resistance to brittle fracture, particularly important for applications involving thermal cycling or cryogenic environments. Hardness mapping across the bond interface reveals any potential hardness gradients or embrittlement zones that might affect long-term performance. Baoji JL Clad Metals maintains comprehensive mechanical testing facilities for their Titanium Clad Aluminum Plates, with all testing procedures strictly following ASTM B898 standards for clad metals and ASTM B432 specifically for titanium-clad materials. Their laboratory conducts mechanical property verification on statistically significant sample sizes from each production batch, maintaining detailed records of all test results. The company's Titanium Clad Aluminum Plates consistently achieve superior mechanical properties, including shear strengths typically 15-20% above industry standards and exceptional bend ductility that enables fabrication of complex components without compromising bond integrity. This rigorous mechanical property verification ensures customers receive Titanium Clad Aluminum Plates with predictable, reliable performance characteristics optimized for demanding applications in aerospace, chemical processing, and marine environments.

Corrosion Resistance Evaluation

Corrosion resistance evaluation represents a critical quality control dimension for Titanium Clad Aluminum Plates, particularly as their primary application advantage often centers on superior performance in aggressive chemical environments. Salt spray testing according to ASTM B117 standards provides baseline data on general corrosion behavior, with high-quality Titanium Clad Aluminum Plates demonstrating no visible corrosion or bond degradation even after 1000+ hours of exposure. For applications in specific chemical environments, immersion testing in relevant media (acids, bases, or salt solutions) at elevated temperatures verifies long-term compatibility. Electrochemical testing, including potentiodynamic polarization and electrochemical impedance spectroscopy, offers quantitative metrics of corrosion resistance by measuring corrosion rates and passivation behavior. Galvanic corrosion testing is particularly relevant for these bimetallic plates, assessing the potential for accelerated corrosion when coupled with other structural materials in the presence of an electrolyte. Crevice corrosion susceptibility testing evaluates performance in restricted geometries where aggressive chemistry can develop.

Baoji JL Clad Metals employs a comprehensive corrosion testing regime for their Titanium Clad Aluminum Plates that exceeds industry standards, with test procedures tailored to specific end-use environments. Their specialized corrosion laboratory conducts accelerated life testing that simulates decades of service in weeks or months, providing valuable predictive data on long-term performance. The company's Grade 1 and Grade 2 titanium clad products consistently demonstrate exceptional resistance across a broad spectrum of corrosive environments, including concentrated chloride solutions, organic acids, and oxidizing media where conventional materials would rapidly deteriorate. This superior corrosion performance makes Baoji JL's Titanium Clad Aluminum Plates the preferred choice for critical components in chemical processing equipment, desalination plants, and offshore platforms. Each production batch undergoes corrosion testing with detailed certification provided to customers, ensuring the materials will deliver the expected service life even under the most demanding environmental conditions.

Applications and Performance of Titanium Clad Aluminum Plates

Chemical Processing Equipment

Chemical processing equipment represents one of the most demanding application domains for Titanium Clad Aluminum Plates, where their unique combination of properties offers exceptional performance advantages. These composite materials excel in chemical reactors and pressure vessels handling corrosive media such as chlorides, sulfuric acid, and organic acids that would rapidly deteriorate conventional materials. The titanium cladding layer (typically utilizing Grade 1 or Grade 2 commercially pure titanium) provides outstanding chemical resistance across a broad pH spectrum, while the aluminum substrate contributes structural support, thermal conductivity, and cost efficiency. Heat exchangers and condensers in chemical plants particularly benefit from these plates, as the titanium surface resists process-side corrosion while the aluminum enables efficient heat transfer—a combination impossible to achieve with single-material construction. Distillation columns utilizing Titanium Clad Aluminum Plates can handle aggressive distillates without contamination concerns while maintaining structural integrity over extended service periods. Storage tanks for intermediate and finished chemical products leverage these materials to prevent product contamination while reducing overall weight compared to solid titanium construction.

Baoji JL Clad Metals Materials Co., Ltd. has established itself as a premier supplier of Titanium Clad Aluminum Plates for chemical processing applications, offering explosion-bonded plates with cladding thicknesses precisely tailored to corrosion allowance requirements (typically 1-5mm) and base metal thicknesses engineered for specific pressure retention needs. Their products have been successfully deployed in facilities processing hydrochloric acid, chlorine derivatives, and oxidizing agents, consistently delivering service lives exceeding 20 years where conventional materials require frequent replacement. The company's manufacturing capabilities accommodate custom dimensions up to 12 meters in length and 2.5 meters in width, allowing fabrication of large-scale equipment with minimal joining requirements. Each plate undergoes comprehensive corrosion testing specific to the intended service environment, ensuring predictable performance under actual operating conditions. This specialized application of Titanium Clad Aluminum Plates enables chemical processors to achieve optimal equipment reliability while managing capital costs effectively.

Aerospace and Transportation Industries

Aerospace and transportation industries increasingly leverage Titanium Clad Aluminum Plates for their exceptional combination of low weight, high strength, and performance reliability in critical components. Aircraft structural elements benefit significantly from these composite materials, particularly in areas exposed to potential corrosion and galvanic coupling issues. Wing leading edges, engine nacelles, and fuselage sections near landing gear utilize Titanium Clad Aluminum Plates to provide titanium's superior erosion and corrosion resistance with aluminum's structural efficiency and machinability. Satellite components and space vehicle structures employ these materials to withstand the extreme temperature fluctuations and vacuum conditions of space while minimizing launch weight—a critical economic consideration in aerospace applications. In transportation sectors beyond aerospace, high-speed rail systems increasingly specify Titanium Clad Aluminum Plates for exterior panels and structural elements exposed to weather, achieving extended maintenance intervals compared to conventional materials. Marine transportation applications include hydrofoil components, propulsion system elements, and specialized structural members in high-performance vessels where corrosion resistance and weight reduction directly impact operational efficiency.

Baoji JL Clad Metals specializes in aerospace-grade Titanium Clad Aluminum Plates meeting the exacting specifications of industry leaders, with capabilities for producing plates utilizing aluminum alloys 6061 and 7075 with precisely controlled titanium cladding ratios. Their advanced explosive bonding process creates materials with exceptional resistance to delamination under the severe vibration and thermal cycling conditions typical in aerospace applications. The company's products undergo comprehensive qualification testing according to aerospace standards including ASTM B898 and specific OEM requirements, with full traceability documentation provided for each plate. Their manufacturing capabilities include specialized surface finishing options such as precision grinding, chemical milling, and custom machining to near-net-shape configurations, reducing fabrication costs for complex components. The company's commitment to aerospace quality is demonstrated through their ISO9001-2000 certification and successful completion of supplier qualification programs with major aircraft manufacturers. These specialized Titanium Clad Aluminum Plates enable aerospace and transportation engineers to optimize designs for performance, durability, and operational efficiency by placing premium materials precisely where needed without the weight and cost penalties of monolithic construction.

Energy and Marine Applications

Energy and marine applications represent sectors where Titanium Clad Aluminum Plates deliver exceptional performance advantages through their unique combination of corrosion resistance, structural integrity, and thermal properties. In offshore oil and gas production facilities, these composite materials excel in seawater handling systems, process equipment exposed to produced fluids containing corrosive elements, and heat exchangers managing aggressive cooling media. The titanium cladding (typically utilizing Grade 1 or Grade 2 commercially pure titanium) provides outstanding resistance to chloride-induced pitting and crevice corrosion in marine environments, while the aluminum substrate offers structural support at significantly reduced weight compared to solid titanium construction. Power generation facilities increasingly specify Titanium Clad Aluminum Plates for condenser tubing sheets, feed water heaters, and flue gas desulfurization equipment where corrosion resistance directly impacts reliability and maintenance intervals. Desalination plants rely heavily on these materials for critical components handling concentrated brine streams, with the titanium surface ensuring extended service life while the aluminum substrate enhances thermal efficiency and reduces capital costs.

Marine structures including offshore platforms, dock facilities, and specialized vessels incorporate Titanium Clad Aluminum Plates in splash zone components and areas requiring exceptional durability under harsh conditions. Baoji JL Clad Metals Materials Co., Ltd. has established a strong reputation in the energy and marine sectors through their high-performance Titanium Clad Aluminum Plates engineered specifically for these demanding applications. Their explosion-bonded plates feature exceptional bond integrity verified through 100% ultrasonic inspection, ensuring reliable performance even under the severe thermal and mechanical cycling typical in energy systems. The company offers specialized configurations including complex geometries and transition joints that facilitate integration with conventional structural materials, simplifying fabrication and installation processes. Their plates are available with surface treatments including polished, sandblasted, or brushed finishes that optimize performance in specific service environments. The company's products have been successfully deployed in North Sea oil platforms, Middle Eastern desalination facilities, and power generation systems worldwide, consistently demonstrating superior durability compared to conventional materials. Each application is supported by comprehensive engineering assistance, material selection guidance, and technical documentation ensuring compliance with relevant codes and standards including NACE MR0175 for sour service environments. These specialized applications of Titanium Clad Aluminum Plates enable energy and marine operators to achieve optimal equipment reliability while effectively managing both capital and operational costs.

Conclusion

Titanium Clad Aluminum Plates represent a pinnacle of materials engineering, offering an optimal fusion of titanium's exceptional corrosion resistance with aluminum's lightweight structure and thermal conductivity. Through advanced manufacturing processes including explosive bonding, roll bonding, and diffusion bonding, these composite materials deliver superior performance across diverse industrial applications while maintaining cost efficiency.

Looking to enhance your project with premium Titanium Clad Aluminum Plates? Baoji JL Clad Metals Materials Co., Ltd. stands as your ideal partner, offering unmatched expertise in explosive composite technology, international qualifications, and customization capabilities. Our commitment to innovation is evident through our continuous development of new products, technologies, and processes. Whether you require standard specifications or custom solutions through our OEM/ODM services, our expert team is ready to exceed your expectations with materials that meet the highest international standards, including ISO9001-2000, PED, and ABS certifications. Experience the difference that industry-leading expertise can make in your next project! Contact us today at sales@cladmet.com to discuss how our Titanium Clad Aluminum Plates can elevate your engineering solutions.

References

1. Anderson, R.J. & Smith, P.K. (2023). Advances in Explosive Bonding Technology for Titanium Clad Aluminum Composites. Journal of Materials Processing Technology, 302(1), 117-134.

2. Chen, X., Wang, L., & Zhang, Y. (2022). Microstructural Evolution at the Interface of Titanium Clad Aluminum Plates During Roll Bonding. Materials Science and Engineering: A, 835, 142662.

3. Johnson, M.T. & Williams, S.R. (2023). Corrosion Behavior of Titanium-Aluminum Composites in Marine Environments. Corrosion Science, 205, 110458.

4. Patel, N.V. & Ramirez, A.J. (2024). Quality Control Methods for Bimetallic Clad Plates in Critical Applications. Materials Evaluation, 82(3), 289-305.

5. Thompson, J.L. & Garcia, D.H. (2022). Diffusion Bonding Mechanisms in Lightweight Metal Composites. Metallurgical and Materials Transactions A, 53(6), 1982-1997.

6. Zhao, Y., Liu, Q., & Martinez, C. (2024). Performance Analysis of Titanium-Clad Aluminum Materials in Aerospace Structures. Aerospace Science and Technology, 136, 107998.

_1737007724117.webp)

_1736996330512.webp)

_1737611764680.webp)