Explosive Clad Metal Technology: Pioneering the Future with Baoji JL Clad Metals

2025-01-12 10:50:31

2025-01-12 10:50:31

Explosive cladding, a groundbreaking method in metallurgical engineering, is reshaping the manufacturing of advanced metal composites. As industries increasingly demand materials that combine durability, cost-efficiency, and exceptional performance, companies like Baoji JL Clad Metals Materials Co., Ltd have become instrumental in advancing this technology. Founded in 1988, JL CLAD METALS stands out as a leader in the field, specializing in the production and development of EXW clad metals and a wide range of titanium materials.

Exploring the Fundamentals of Explosive Cladding

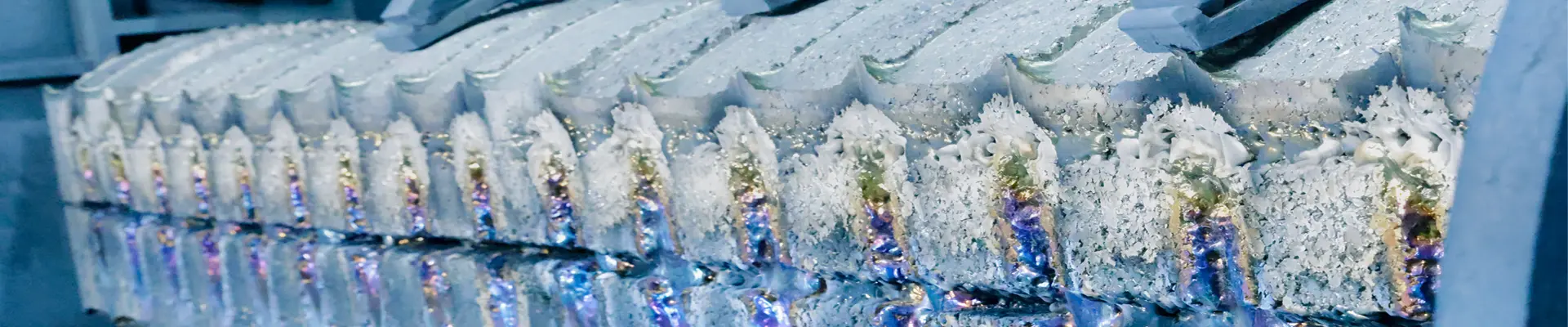

Explosive cladding leverages controlled explosive energy to create a high-energy impact between two or more metal surfaces, forging a metallurgical bond. This process enables the fusion of dissimilar metals without altering their fundamental properties, making it a preferred choice for applications requiring high-performance materials. Key steps in the process include:

Metal Preparation: Cleaning and aligning metal surfaces to ensure optimal bonding conditions.

Explosive Loading: Precisely placing explosives to generate the required energy for bonding.

Detonation: Triggering an explosion to create a high-pressure wave that permanently bonds the metals.

Post-Bonding Treatment: Conducting inspections and finishing processes to ensure product quality.

Baoji JL Clad Metals: Setting the Benchmark

Located in China’s High-tech Development District, Baoji JL Clad Metals has established itself as a key manufacturer of clad metal products. Over the past three decades, the company has made significant contributions to the global market by combining advanced R&D capabilities with a commitment to quality and innovation.

Collaborative Innovation

JL CLAD METALS’ success is rooted in strategic collaborations with leading research institutes and industrial partners. Notable collaborators include Kunming Technology University, China North-West Industrial University, and the China North-West Nonferrous Metals Research Institute. These partnerships have fostered the development of:

Advanced explosion bonding techniques.

Multi-metal layer systems tailored to specific industry requirements.

Sustainable production methods that align with global environmental standards.

Quality Assurance and Certifications

The company’s adherence to international standards, including GB/GBT, ASME/ASTM, and JIS, ensures the reliability and consistency of its products. Achieving ISO9001-2000 certification ahead of its peers was a significant milestone. In 2024, JL CLAD METALS solidified its global standing by obtaining PED and ABS certifications, further enhancing its credibility.

Diverse Product Offerings

JL CLAD METALS provides an extensive range of products designed to meet the specific needs of various industries. Their key offerings include:

Titanium Clad Plates: Combining lightweight properties with excellent corrosion resistance, these are ideal for marine and chemical applications.

Nickel Clad Plates: Known for their durability in high-temperature environments, these plates are widely used in power generation and petrochemical sectors.

Tantalum and Zirconium Clad Plates: Preferred for their exceptional chemical resistance, particularly in pharmaceutical and nuclear industries.

Copper-Aluminum Clad Plates: Delivering superior electrical conductivity, these are indispensable in electronics and power systems.

Stainless Steel Clad Plates: Offering versatility and cost efficiency for general industrial applications.

Applications Across Multiple Sectors

The versatility of JL CLAD METALS’ products has made them indispensable in various industries:

1. Chemical Processing

Explosive clad metals are highly effective in combating corrosion in chemical processing plants. For example, titanium-clad reactors and storage tanks provide long-term performance in environments with aggressive acids and chemicals.

2. Oil and Gas

In oil and gas operations, materials must withstand extreme pressures and corrosive agents. Nickel and stainless steel-clad plates are used in constructing pressure vessels, heat exchangers, and subsea equipment.

3. Power Generation

Power plants require materials that perform reliably under high temperatures and pressures. JL CLAD METALS’ products, such as nickel and stainless steel clads, enhance the durability of boilers, turbines, and condensers.

4. Environmental Technologies

For wastewater treatment and pollution control systems, durable materials are essential. The corrosion-resistant properties of clad metals make them ideal for scrubbers, separators, and filtration units.

5. Aerospace and Defense

The aerospace and defense industries demand lightweight yet strong materials for critical components. Titanium-clad plates meet these requirements, offering a high strength-to-weight ratio and resistance to extreme conditions.

Commitment to Sustainability

As environmental concerns grow, JL CLAD METALS remains committed to sustainable practices. Their initiatives include:

Reducing waste and optimizing material usage in manufacturing processes.

Adopting energy-efficient production techniques.

Offering recyclable products that minimize environmental impact.

By prioritizing sustainability, JL CLAD METALS not only meets regulatory standards but also aligns with the expectations of environmentally conscious customers.

Future Prospects for Explosive Cladding

The explosive cladding industry is poised for significant growth, driven by increasing demand for advanced materials in emerging sectors such as renewable energy, advanced manufacturing, and biotechnology. Baoji JL Clad Metals is at the forefront of this transformation, focusing on:

Developing Next-Generation Materials: Expanding the range of metal combinations to meet the unique requirements of cutting-edge technologies.

Automating Manufacturing Processes: Incorporating robotics and AI to enhance efficiency and precision.

Expanding Global Reach: Strengthening partnerships and exploring new markets to deliver innovative solutions worldwide.

Global Impact and Customer-Centric Approach

JL CLAD METALS’ dedication to quality, innovation, and customer satisfaction has earned it a prominent position in the global market. By tailoring solutions to the specific needs of clients across industries, the company has built a loyal customer base and a reputation for excellence.

Conclusion

Explosive cladding continues to redefine material engineering, offering unparalleled advantages in durability, performance, and versatility. Baoji JL Clad Metals Materials Co., Ltd has been instrumental in advancing this technology, setting new benchmarks for quality and innovation. As the demand for high-performance materials grows, JL CLAD METALS is poised to lead the industry, driving progress and shaping the future of metallurgical engineering.

_1737007724117.webp)