Advancing the Industry: Baoji JL Clad Metals and the Future of Explosive Cladding

2025-01-12 10:48:22

2025-01-12 10:48:22

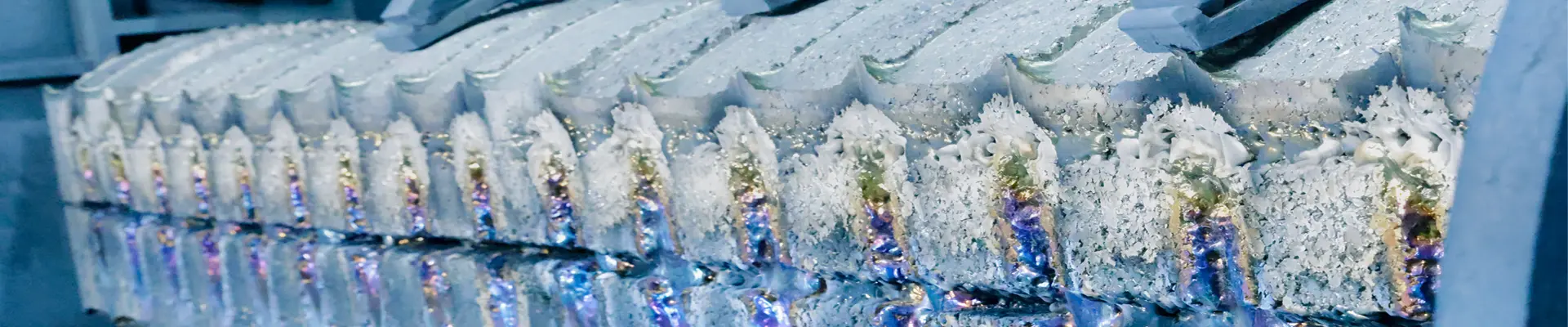

Explosive cladding has revolutionized material engineering, enabling the combination of metals with distinct properties into high-performance, durable products. Baoji JL Clad Metals Materials Co., Ltd., a leading name in the field, has consistently demonstrated innovation and excellence since its establishment in 1988. Based in China’s High-tech Development District, this key manufacturer of EXW clad metals materials has made significant contributions to industries worldwide by creating advanced, high-quality solutions for demanding applications.

Explosive Cladding: An Overview

Explosive cladding, also known as explosive welding, is a metallurgical process that uses controlled explosive energy to bond metals without melting. This process facilitates the creation of strong, corrosion-resistant bonds between dissimilar metals, such as titanium and stainless steel, or copper and aluminum. Key advantages of explosive cladding include:

Unmatched Material Compatibility: The process overcomes the metallurgical incompatibilities of different metals.

Enhanced Performance: Products exhibit superior mechanical strength, corrosion resistance, and thermal conductivity.

Cost Efficiency: Clad materials retain the beneficial properties of premium metals while reducing material costs by combining them with less expensive substrates.

Versatility: Suitable for creating complex, multi-layered configurations for specialized industrial applications.

Baoji JL Clad Metals: A Legacy of Excellence

As a key player in explosive cladding, Baoji JL Clad Metals has achieved remarkable milestones in R&D, manufacturing, and global distribution. With a strong foundation of over three decades, the company continues to lead by leveraging state-of-the-art facilities, strategic partnerships, and adherence to international quality standards.

Collaborations and Innovations

JL CLAD METALS has cultivated long-term collaborations with esteemed institutions such as Kunming Technology University, China North-West Industrial University, and the China North-West Nonferrous Metals Research Institute. These partnerships have fueled groundbreaking innovations in clad metal technology, allowing the company to develop:

Enhanced bonding processes for improved material integrity.

Advanced multi-layered cladding solutions for high-performance applications.

Customizable product designs tailored to client-specific requirements.

Global Certifications and Standards

Demonstrating a steadfast commitment to quality, JL CLAD METALS strictly complies with recognized codes, including GB/GBT, ASME/ASTM, and JIS. It was an early adopter of ISO9001-2000 certification, setting a benchmark for its competitors. In 2024, the company’s dedication to excellence earned it prestigious PED and ABS international qualifications, further validating its global reputation.

Comprehensive Product Range

JL CLAD METALS offers a diverse portfolio of clad metal products designed to meet the evolving needs of modern industries. Its offerings include:

Titanium Clad Plates: Lightweight, corrosion-resistant materials ideal for chemical processing and marine applications.

Nickel Alloy Clad Plates: Preferred for high-temperature and corrosive environments in power generation and chemical industries.

Zirconium and Tantalum Clad Plates: Exceptional resistance to aggressive chemicals, widely used in pharmaceuticals and nuclear technology.

Copper-Aluminum Clad Plates: Combining excellent electrical conductivity with structural strength for electrical and electronic systems.

Stainless Steel Clad Plates: Versatile and cost-effective solutions for a broad range of applications.

Deep Processing Services

In addition to manufacturing high-quality clad metals, JL CLAD METALS offers deep processing services, including:

Fabrication of chemical equipment components.

Production of finished clad metal products tailored to specific industrial needs.

Engineering support to optimize material selection and application design.

Applications Across Key Sectors

JL CLAD METALS’ products are integral to various industries, enhancing performance and durability in critical operations. Notable applications include:

1. Petroleum and Gas

The harsh conditions of the oil and gas industry demand materials with exceptional strength and resistance to corrosion. Titanium and nickel alloy clad plates from JL CLAD METALS are widely used in constructing pressure vessels, heat exchangers, and pipelines.

2. Chemical Processing

Clad metals provide cost-effective solutions for handling corrosive chemicals. Zirconium and tantalum-clad plates ensure long-lasting performance in reactors, storage tanks, and separation units.

3. Power Generation

In power plants, clad metals are indispensable for components exposed to high pressures and temperatures. Stainless steel and nickel alloy clad plates contribute to the reliability and efficiency of boilers, turbines, and condensers.

4. Marine and Offshore

Marine environments pose challenges such as saltwater corrosion and structural fatigue. Titanium and stainless steel-clad materials deliver superior performance in shipbuilding, offshore platforms, and seawater desalination plants.

5. Environmental Protection

Clad metals play a pivotal role in creating durable, corrosion-resistant systems for wastewater treatment and pollution control, including scrubbers, separators, and filtration units.

A Commitment to Sustainability

In an era where sustainability is paramount, JL CLAD METALS prioritizes eco-friendly practices throughout its operations. By optimizing raw material usage, minimizing waste, and adopting energy-efficient processes, the company contributes to reducing the environmental footprint of industrial manufacturing.

The Future of Explosive Cladding

As industries evolve, the demand for advanced materials continues to rise. JL CLAD METALS is well-positioned to lead the next phase of innovation in explosive cladding, focusing on:

Developing new metal combinations for emerging technologies.

Expanding applications in renewable energy, aerospace, and biomedical fields.

Enhancing automation and digitalization in manufacturing processes.

Global Reach and Client-Centric Approach

With a strong presence in both domestic and international markets, JL CLAD METALS serves clients across Asia, Europe, North America, and beyond. Its commitment to delivering customized solutions, on-time delivery, and unparalleled technical support has earned the trust of industry leaders worldwide.

Conclusion

Explosive cladding is a cornerstone of modern material science, enabling the creation of versatile and durable solutions for the most demanding environments. Baoji JL Clad Metals Materials Co., Ltd stands as a trailblazer in this field, combining innovation, quality, and sustainability to meet the needs of a dynamic global market. As it continues to push the boundaries of clad metal technology, JL CLAD METALS reaffirms its role as a key partner in advancing industrial performance and reliability.

_1737007724117.webp)