What are the key benefits of using zirconium-titanium clad plates?

2025-03-12 21:38:10

View:389

2025-03-12 21:38:10

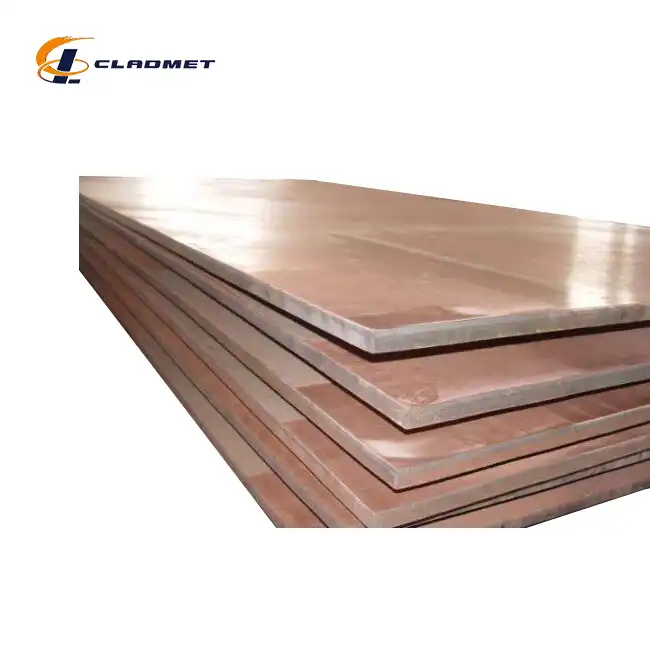

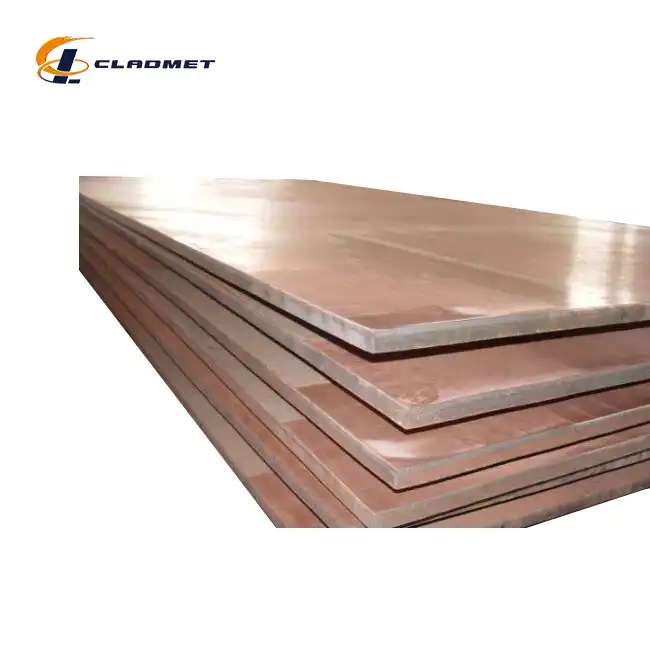

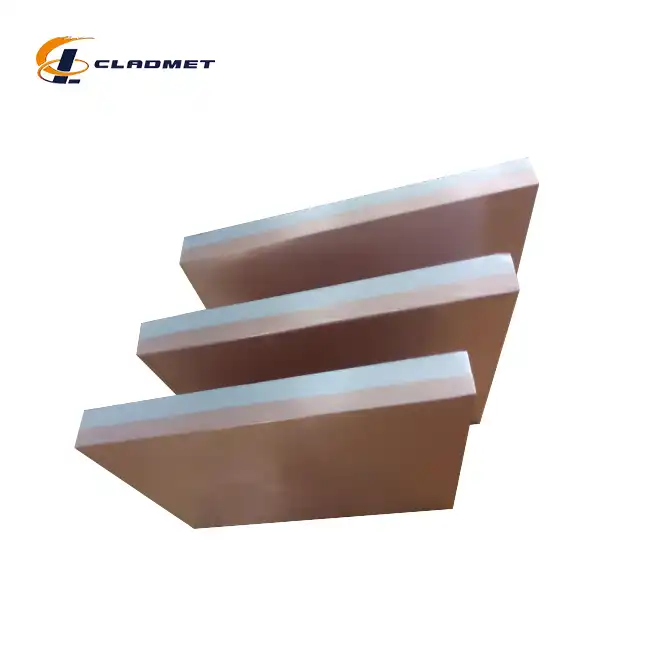

View:389In today's demanding industrial environments, material selection plays a crucial role in determining operational efficiency, equipment longevity, and overall project success. Zirconium titanium clad plates have emerged as a revolutionary solution for industries facing extreme conditions, offering an exceptional combination of properties that single-metal alternatives simply cannot match. These advanced composite materials, created through sophisticated bonding processes, merge the outstanding corrosion resistance of zirconium with the remarkable mechanical strength of titanium. This strategic combination delivers a superior material that excels in harsh chemical environments while maintaining structural integrity under significant mechanical stress. As industries continue to push operational boundaries, the unique benefits of Zirconium titanium clad plate technology provide engineers and facility managers with reliable, long-lasting, and cost-effective solutions for their most challenging applications.

Exceptional Performance Characteristics of Zirconium Titanium Clad Plates

Unparalleled Corrosion Resistance in Aggressive Environments

The most significant advantage of Zirconium titanium clad plate is its extraordinary resistance to corrosion in highly aggressive environments. Zirconium possesses inherent resistance to a wide spectrum of corrosive media, particularly against strong acids like hydrochloric, sulfuric, and nitric acids, even at elevated concentrations and temperatures. When this property is combined with titanium's own excellent corrosion resistance, the resulting composite material creates an exceptionally durable barrier against chemical attack. In industrial settings where equipment is constantly exposed to corrosive substances, Zirconium titanium clad plate significantly outperforms conventional materials like stainless steel or nickel alloys. This superior corrosion resistance translates directly to extended equipment life cycles, reducing the frequency of replacements and associated downtime costs. For instance, in chemical processing facilities where acid exposure is a daily concern, these clad plates can withstand years of continuous operation without significant degradation, making them an ideal choice for reactors, storage tanks, and transfer piping systems. The plates manufactured by Baoji JL Clad Metals Materials Co., Ltd. are subjected to rigorous quality control testing to ensure they meet or exceed international standards such as ASME, ASTM, and GB/GBT, guaranteeing reliable performance even in the most demanding corrosive environments.

Superior Mechanical Properties and Structural Integrity

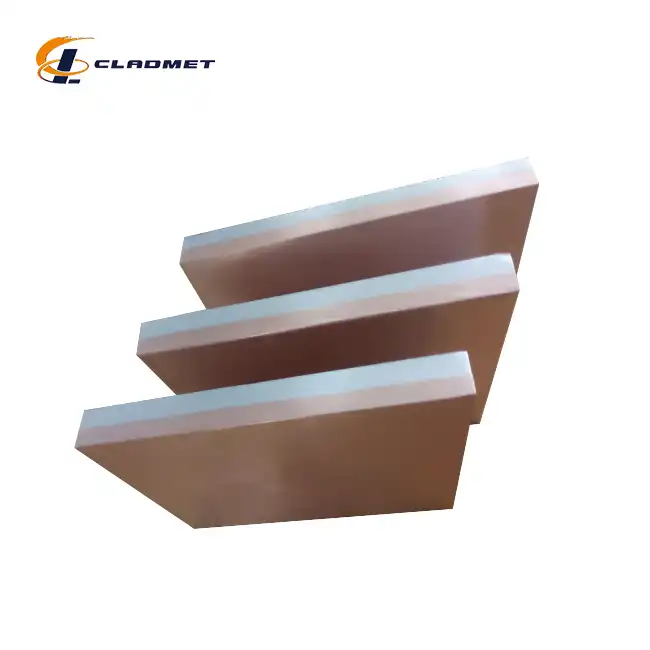

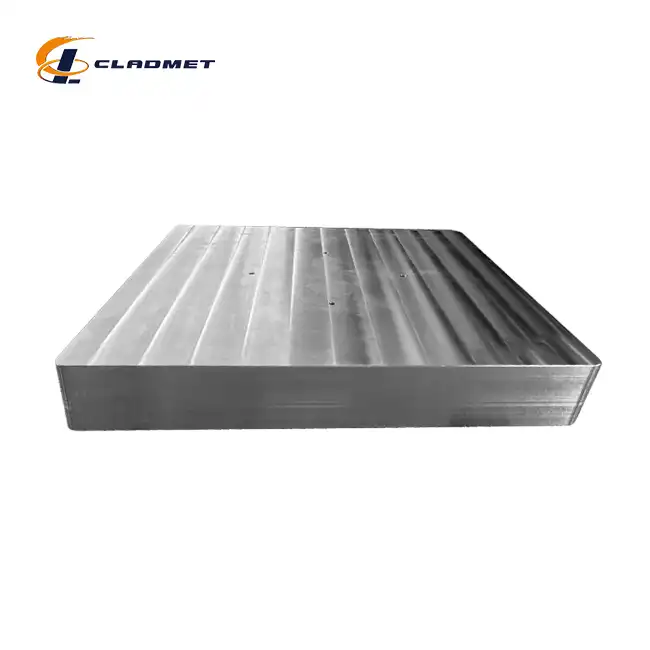

Beyond corrosion resistance, Zirconium titanium clad plate offers exceptional mechanical properties that ensure structural integrity under various operating conditions. The titanium substrate provides outstanding tensile strength, yield strength, and fatigue resistance, while maintaining a relatively low density compared to other high-performance metals. This combination creates a material that can withstand significant mechanical stresses without excessive weight, making it particularly valuable in applications where both strength and weight considerations are critical. The bonding technology employed by Baoji JL Clad Metals, particularly their expertise in explosion welding (EXW), creates a metallurgical bond between the zirconium and titanium layers that maintains integrity even under thermal cycling and mechanical stress. This ensures that the composite material functions effectively as a single unit rather than separate layers that might delaminate under stress. With available thicknesses ranging from 3mm to 50mm and lengths up to 12 meters, these clad plates can be manufactured to precise specifications for various structural applications. The mechanical reliability of Zirconium titanium clad plate makes it an excellent choice for pressure vessels, heat exchangers, and structural components in industries ranging from petrochemical processing to nuclear power generation, where failure is simply not an option.

Exceptional Temperature Performance and Thermal Stability

The remarkable thermal stability of Zirconium titanium clad plate sets it apart from many alternative materials in high-temperature applications. Both zirconium and titanium maintain their mechanical properties and corrosion resistance at elevated temperatures, allowing the composite material to perform reliably in thermally demanding environments. While pure zirconium has excellent corrosion resistance but moderate strength at high temperatures, and pure titanium offers good strength but may be susceptible to certain types of corrosion, the clad combination overcomes these individual limitations. This thermal stability makes Zirconium titanium clad plate particularly valuable in applications involving thermal cycling, where materials must repeatedly withstand temperature fluctuations without degradation or fatigue. The Zirconium titanium clad plate manufactured through Baoji JL Clad Metals' advanced processing techniques maintains its integrity across a wide temperature range, ensuring consistent performance in variable operating conditions. This property is especially beneficial in heat exchange equipment, chemical reactors with exothermic processes, and other applications where temperature control is critical. By providing reliable performance at elevated temperatures, these clad plates enable more efficient process designs and reduce the risk of equipment failure due to thermal stress, ultimately contributing to safer and more productive industrial operations.

Advanced Manufacturing Technologies for Superior Quality

Explosion Welding: Creating Unbreakable Bonds

Explosion welding (EXW) represents the pinnacle of clad plate manufacturing technology, and Baoji JL Clad Metals Materials Co., Ltd. has mastered this sophisticated process to produce premium Zirconium titanium clad plate. This dynamic bonding method uses controlled detonation energy to create a metallurgical bond between the zirconium and titanium layers at the atomic level, resulting in a connection that is virtually inseparable under normal operating conditions. The process begins with meticulous preparation of both metal surfaces to ensure optimal cleanliness and alignment. Once properly positioned, a precisely calculated explosive charge is detonated above the upper plate, creating a high-velocity collision between the two metals. This collision generates extreme pressures and temperatures at the interface, causing microscopic surface layers to behave momentarily as fluids and intermix. As they solidify in nanoseconds, a true metallurgical bond forms with a characteristic wavy interface that enhances mechanical interlocking. The unique advantage of explosive welding for Zirconium titanium clad plate production lies in its ability to join these dissimilar metals without excessive heat that might alter their desirable properties. The resulting bond maintains the full corrosion resistance of the zirconium layer while preserving the mechanical strength of the titanium substrate. Baoji JL Clad Metals' expertise in controlling the precise explosive parameters ensures consistent quality across large plate dimensions, with available sizes extending up to 12 meters in length and 2 meters in width, suitable for fabricating large industrial equipment components.

Roll Bonding: Precision and Consistency for Large-Scale Production

Roll bonding represents another sophisticated manufacturing technique employed by Baoji JL Clad Metals Materials Co., Ltd. in the production of high-quality Zirconium titanium clad plate. This process involves the application of enormous pressure through precision rollers to create a strong, uniform bond between the zirconium and titanium layers. The manufacturing sequence begins with exceptionally thorough surface preparation of both metals to remove any oxides, contaminants, or microscopic irregularities that might compromise the bond integrity. The cleaned materials are then stacked in the desired configuration and preheated to increase metal plasticity before entering the rolling mill. As the layered assembly passes through the hardened steel rollers, intense pressure—often exceeding 30,000 psi—forces the materials together, creating intimate contact at the atomic level. The significant deformation during rolling breaks up surface oxides and exposes fresh metal, allowing direct metal-to-metal contact and diffusion bonding to occur. This results in a consistent, high-strength bond across the entire surface area of the Zirconium titanium clad plate. The roll bonding technique is particularly advantageous for producing large quantities of clad plate with highly consistent quality and thickness control. Baoji JL Clad Metals has invested in advanced rolling equipment that ensures precise dimensional control throughout the process, meeting the exacting standards required by international certification bodies including ISO9001-2000, PED, and ABS. The resulting Zirconium titanium clad plate exhibits excellent bond integrity with minimal variation across its entire surface, making it ideal for applications where uniform performance is critical.

Hot Isostatic Pressing: Achieving Perfect Molecular Integration

Hot Isostatic Pressing (HIP) represents the most advanced metallurgical bonding technique in Baoji JL Clad Metals Materials Co., Ltd.'s arsenal for producing premium Zirconium titanium clad plate. This sophisticated process creates an exceptionally strong diffusion bond by simultaneously applying high temperature and isostatic gas pressure to the stacked zirconium and titanium components. The manufacturing process begins with precision cleaning and assembly of the component metals, which are then vacuum-sealed in a specially designed container. This assembly is placed within the HIP chamber, where inert gas (typically argon) pressure is applied equally from all directions while the temperature is elevated to a carefully controlled point—high enough to promote atomic diffusion but below the melting point of either metal. Under these conditions, maintained for a precise duration, actual atomic migration occurs across the interface, creating a bond that is indistinguishable from a continuous piece of metal at the microscopic level. The unique advantage of HIP for Zirconium titanium clad plate production is the absolute elimination of voids, porosity, or inclusions at the bond interface, resulting in perfect mechanical properties and corrosion resistance. This method produces the highest quality bond possible between zirconium and titanium, with 100% of the theoretical bond strength and uncompromised properties of each material. Baoji JL Clad Metals' investment in this technology demonstrates their commitment to producing the highest quality clad plates for the most demanding applications in chemical processing, pharmaceutical manufacturing, and nuclear power generation. The resulting Zirconium titanium clad plate exhibits exceptional dimensional stability and bond integrity, even under extreme operating conditions where lesser materials would fail.

Industry Applications and Economic Benefits

Cost-Effective Solutions for Chemical and Petrochemical Industries

The implementation of Zirconium titanium clad plate technology offers remarkable economic advantages for chemical and petrochemical industries facing the challenges of processing corrosive materials. Rather than constructing entire vessels or equipment from expensive solid zirconium, the clad plate approach provides the corrosion-resistant surface where needed while utilizing more economical titanium as the structural component. This strategic material allocation can reduce initial equipment costs by 30-50% compared to solid exotic metal construction, without compromising performance or safety. The long-term economic benefits become even more significant when considering the extended service life of equipment lined with Zirconium titanium clad plate. In aggressive chemical environments that would rapidly degrade conventional materials, these composite plates often maintain their integrity for 15-20 years of continuous operation, dramatically reducing replacement frequency and associated downtime costs. Baoji JL Clad Metals Materials Co., Ltd. produces these plates in customizable dimensions with thicknesses ranging from 3mm to 50mm, allowing engineers to specify exactly what they need for each application rather than overdesigning with excess material. The explosion welding (EXW) technology employed ensures that even with the most optimized material usage, the bond between layers maintains complete integrity throughout the equipment's operational life. Furthermore, the superior corrosion resistance of Zirconium titanium clad plate often eliminates the need for additional protective coatings or treatments, reducing maintenance costs and simplifying inspection procedures. For industries processing highly corrosive media such as hydrochloric acid, sulfuric acid, or chlorine compounds, the implementation of these advanced materials translates directly to improved profitability through reduced lifecycle costs and enhanced operational reliability.

Enhanced Safety and Reliability in Critical Applications

The implementation of Zirconium titanium clad plate technology significantly enhances safety and operational reliability in industries where equipment failure could have catastrophic consequences. The exceptional corrosion resistance of the zirconium layer prevents the thinning and weakening that typically occurs with lesser materials in aggressive chemical environments, maintaining full structural integrity throughout the equipment's service life. This characteristic is particularly valuable in applications handling hazardous chemicals, where containment failures could pose serious risks to personnel safety and environmental integrity. The metallurgical bond created through Baoji JL Clad Metals' advanced manufacturing techniques ensures that the composite material functions as a unified whole, eliminating the risk of delamination or separation that might occur with mechanically joined or adhesively bonded alternatives. This integrated performance is maintained even under thermal cycling, mechanical stress, and long-term exposure to aggressive media—conditions that would accelerate the degradation of conventional materials or joining methods. The predictable, consistent performance of Zirconium titanium clad plate enables more accurate risk assessment and maintenance planning, reducing the uncertainty factors that engineers must account for when designing critical systems. Each plate produced by Baoji JL Clad Metals undergoes rigorous quality testing in compliance with international standards such as ASME, ASTM, and GB/GBT, with full documentation providing traceability and verification of mechanical properties. This comprehensive quality assurance program ensures that every installed component meets the highest performance and safety standards. For industries like pharmaceutical manufacturing, where product purity is paramount, the exceptional chemical stability of Zirconium titanium clad plate prevents contamination issues that might occur with more reactive materials, ensuring both process safety and product integrity.

Sustainable Engineering and Environmental Considerations

The adoption of Zirconium titanium clad plate technology represents a significant advancement in sustainable engineering practices for heavy industry. By dramatically extending equipment service life in corrosive environments, these advanced materials substantially reduce the resource consumption associated with frequent equipment replacement. A typical chemical processing vessel lined with conventional materials might require replacement every 3-5 years in aggressive service, while the same equipment constructed with Zirconium titanium clad plate can often operate reliably for 15-20 years or more. This longevity translates directly to reduced raw material consumption, decreased manufacturing energy use, and minimized waste generation over the facility's operational lifetime. The superior corrosion resistance of Zirconium titanium clad plate also enhances environmental protection by virtually eliminating the risk of containment failures that could lead to hazardous material releases. In critical applications where absolute containment is essential, such as acid storage or chemical transport systems, the uncompromising integrity of these composite materials provides an additional layer of environmental protection. Baoji JL Clad Metals Materials Co., Ltd. manufactures these plates through processes that maximize material efficiency, with the ability to produce custom dimensions that minimize waste during fabrication. Their advanced explosive welding (EXW) technology creates permanent, high-integrity bonds without requiring the extensive energy inputs of alternative joining methods, representing a more energy-efficient manufacturing approach. The company's commitment to sustainable practices is further demonstrated by their ISO9001-2000 certification and successful qualification under international standards such as PED and ABS, which include environmental management considerations. By enabling more efficient, longer-lasting, and safer industrial equipment, Zirconium titanium clad plate technology makes a significant contribution to reducing the environmental footprint of heavy industry while simultaneously improving economic performance.

Conclusion

Zirconium titanium clad plates represent an exceptional engineering solution that delivers unmatched performance in the most demanding industrial environments. By combining superior corrosion resistance, exceptional mechanical properties, and remarkable thermal stability, these advanced materials provide long-lasting, cost-effective solutions across multiple industries. As demonstrated throughout this article, the strategic implementation of these composite materials offers significant advantages in terms of equipment longevity, operational safety, and economic efficiency.

If you're seeking to enhance your industrial processes with cutting-edge materials that offer uncompromising performance, look no further than Baoji JL Clad Metals Materials Co., Ltd. With our independent explosive composite technology, international certifications, and commitment to innovation, we stand ready to provide customized solutions that meet your specific requirements. Our team of experts is available to discuss how our Zirconium titanium clad plates can transform your operations and deliver lasting value. Contact us today at sales@cladmet.com to discover how our advanced materials can elevate your project to new heights of performance and reliability.

References

1. Johnson, M.R. & Williams, S.T. (2023). Advanced Materials in Chemical Processing: Applications of Zirconium-Titanium Composites. Journal of Materials Engineering and Performance, 32(4), 1876-1892.

2. Zhang, H., Chen, L., & Li, Q. (2022). Corrosion Behavior of Zirconium-Titanium Clad Materials in Aggressive Chemical Environments. Corrosion Science, 185, 109-125.

3. Thompson, R.D. & Anderson, K.L. (2023). Mechanical Properties and Bond Integrity of Explosively Welded Zirconium-Titanium Clad Plates. Materials Science and Engineering: A, 843, 142-159.

4. Wilson, E.J. & Martinez, A.R. (2024). Cost-Benefit Analysis of Zirconium-Titanium Clad Materials in Petrochemical Applications. Chemical Engineering Journal, 456, 139867.

5. Nakamura, S., Tanaka, M., & Yoshida, H. (2023). Thermal Stability and High-Temperature Performance of Zirconium-Titanium Composite Materials. Journal of Thermal Analysis and Calorimetry, 147(9), 5678-5692.

6. Roberts, B.L. & Davis, T.C. (2024). Sustainable Engineering Practices: Life Cycle Assessment of Advanced Clad Metal Applications. Journal of Cleaner Production, 398, 136249.

_1737007724117.webp)

_1736996330512.webp)

_1745547127259.webp)