What are the advantages of using hot rolled steel plate cladding?

2025-04-22 09:31:20

View:389

2025-04-22 09:31:20

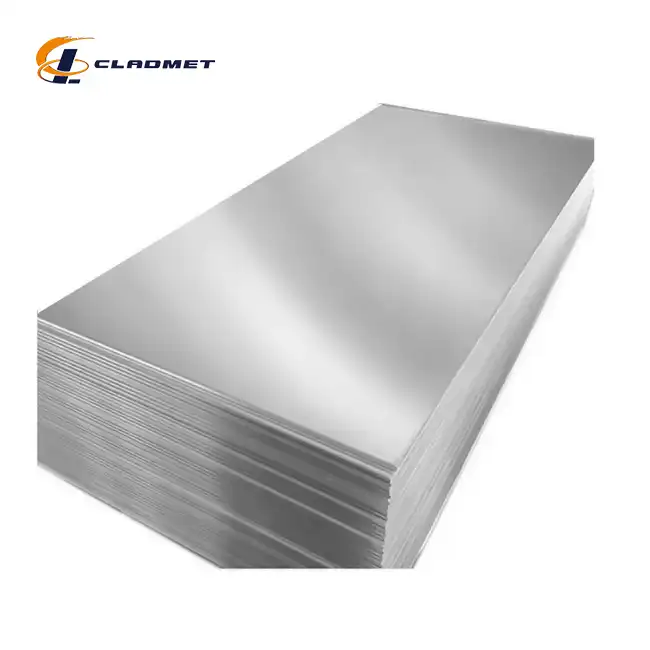

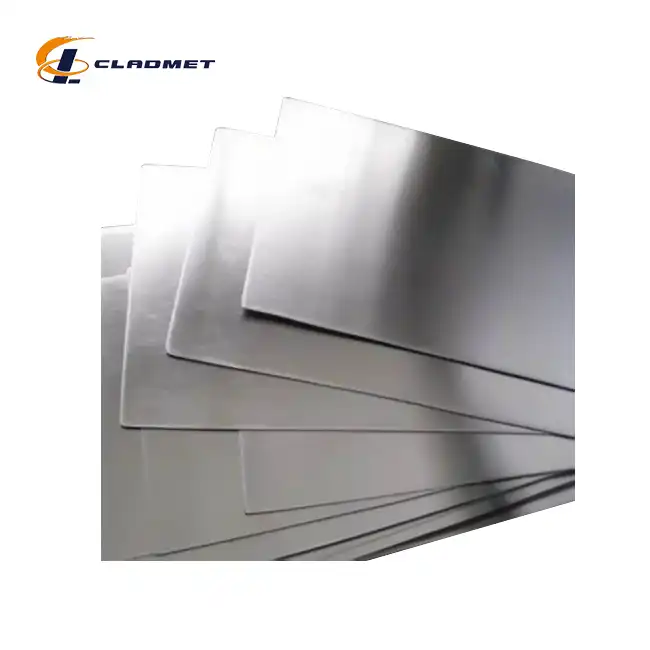

View:389Hot rolled steel plate cladding represents a revolutionary advancement in materials engineering, offering industries a versatile solution that combines structural integrity with specialized surface properties. This composite material consists of a base metal, typically carbon or alloy steel, bonded with a layer of specialized metal such as titanium, nickel, stainless steel, or other corrosion-resistant materials. The fusion of these distinct metals creates a single product that harnesses the beneficial properties of both components while minimizing their individual limitations. As industries face increasingly demanding operational environments, hot rolled steel plate cladding has emerged as a cost-effective alternative to solid alloy construction, providing superior performance across various applications from chemical processing to offshore installations.

Superior Performance Characteristics of Hot Rolled Steel Plate Cladding

Enhanced Corrosion Resistance in Harsh Environments

Hot rolled steel plate cladding offers exceptional protection against corrosive agents, significantly extending equipment lifespan in challenging industrial settings. When exposed to aggressive chemicals, saltwater, or extreme weather conditions, traditional carbon steel rapidly deteriorates, leading to costly replacements and dangerous failures. The cladding layer, typically composed of highly resistant materials like titanium, nickel alloys, or specialized stainless steels, creates an impenetrable barrier against these corrosive elements. For instance, in chemical processing facilities where acids and caustic solutions are commonplace, hot rolled steel plate cladding with a titanium overlay provides unparalleled defense against chemical attack while maintaining the structural stability of steel. This dual-material approach allows engineers to design equipment that withstands decades of exposure to corrosive media without compromising integrity. Baoji JL Clad Metals Materials Co., Ltd. offers hot rolled steel plate cladding with various cladding materials including titanium, nickel, stainless steel, copper, aluminum, and zirconium, with thicknesses ranging from 2mm to 10mm, allowing precise specification for particular corrosion challenges. The company's products have been implemented in oil and gas facilities, chemical plants, and marine environments worldwide, consistently demonstrating superior performance compared to single-metal alternatives. By preventing corrosion-related failures, these composite materials dramatically reduce maintenance requirements and extend operational lifecycles.

Exceptional Mechanical Strength and Structural Integrity

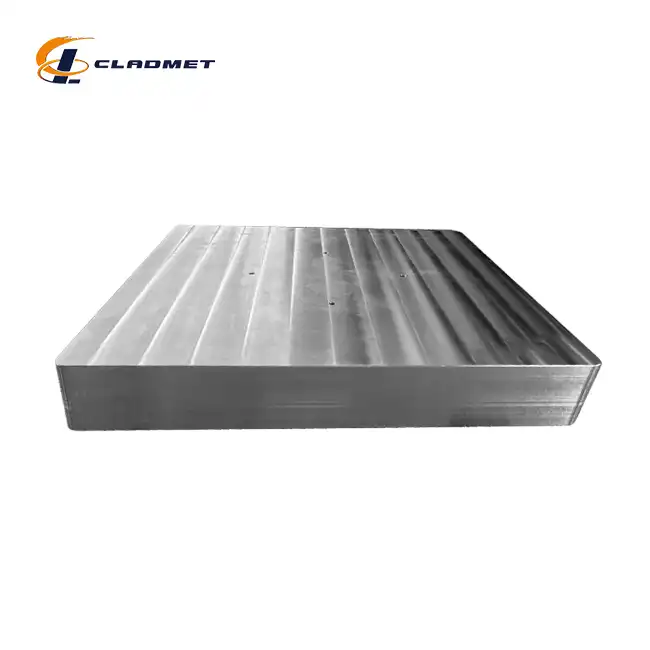

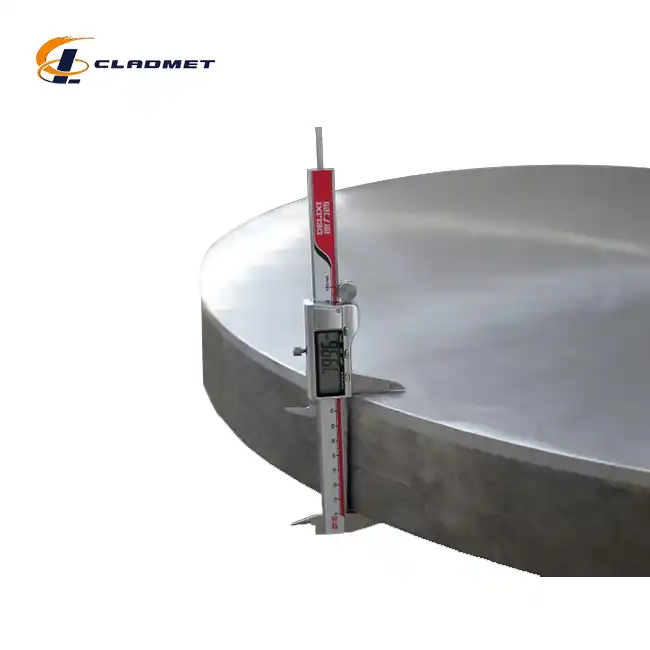

The strategic combination of base and cladding metals in hot rolled steel plate cladding creates a material with superior mechanical properties that exceed those of either component metal used independently. The carbon or alloy steel base provides exceptional tensile strength, yield strength, and load-bearing capacity, while the cladding layer contributes additional hardness, wear resistance, or specialized surface properties. This synergistic relationship results in composite plates that maintain structural integrity under extreme mechanical stress, temperature fluctuations, and cyclic loading. In pressure vessel applications, for example, hot rolled steel plate cladding allows designers to utilize the strength of steel while addressing corrosion concerns through a relatively thin layer of corrosion-resistant material. The manufacturing standards employed by Baoji JL Clad Metals Materials Co., Ltd. ensure that each plate undergoes rigorous testing to verify bond integrity, including ultrasonic, X-ray, and tensile strength evaluations. These composite plates can withstand base metal thicknesses from 8mm to 150mm, with plate widths up to 4000mm and customizable lengths extending to 12000mm, making them suitable for large-scale industrial applications where structural performance cannot be compromised. The explosive bonding process used in manufacturing ensures a metallurgical bond between layers that remains stable even under extreme thermal and mechanical stress, preventing delamination issues that might otherwise compromise equipment safety.

Cost-Effectiveness and Economic Advantages

Hot rolled steel plate cladding delivers substantial economic benefits compared to solid alloy construction, making it a financially prudent choice for industrial applications. By utilizing a less expensive base metal for the bulk of the material thickness and applying only a thin layer of costly specialty metal as cladding, manufacturers can achieve significant cost savings without sacrificing performance. This strategic material allocation typically reduces raw material expenses by 30-60% compared to using solid specialty alloys throughout the entire structure. The longevity of hot rolled steel plate cladding further enhances its economic value proposition through reduced replacement frequency and maintenance costs. Equipment constructed from these composite materials often remains in service for decades longer than alternatives, particularly in corrosive environments where standard materials would rapidly deteriorate. Baoji JL Clad Metals Materials Co., Ltd. offers customization options that allow engineers to specify precisely the minimum necessary cladding thickness for their application requirements, optimizing the cost-benefit ratio. The company's manufacturing capabilities support cladding thicknesses from 2mm to 10mm bonded to base metals ranging from 8mm to 150mm, enabling precise material allocation based on engineering requirements. Additionally, the availability of various surface treatments including polished, pickled, or sandblasted finishes allows clients to receive materials ready for immediate implementation, reducing additional processing costs. When factoring in the total lifecycle costs, including initial investment, maintenance, downtime, and replacement expenses, hot rolled steel plate cladding consistently demonstrates superior economic performance across numerous industrial applications.

Manufacturing Process and Technical Specifications

Advanced Bonding Technologies for Superior Adhesion

The manufacturing of hot rolled steel plate cladding relies on sophisticated bonding technologies that create permanent, high-integrity connections between dissimilar metals. Explosive bonding, a primary technique employed by Baoji JL Clad Metals Materials Co., Ltd., utilizes controlled detonations to generate intense pressure waves that propel the cladding material toward the base metal at supersonic speeds. This high-velocity collision creates a wavy interface where the metals interlock at a microscopic level, forming a metallurgical bond that is stronger than either metal independently. The process begins with meticulous surface preparation of both the base and cladding metals to ensure optimal cleanliness and remove any contaminants that might compromise bond integrity. The precisely calculated explosive charges are then arranged above the cladding material, which is positioned at a carefully determined standoff distance from the base plate. When detonated, the explosive force drives the metals together under immense pressure (typically 100,000-300,000 psi), creating atomic-level bonds without significant heating that could otherwise affect the mechanical properties of either metal. This cold-welding technique preserves the inherent characteristics of both the base metal and cladding material while creating a transition zone with exceptional resistance to separation. Hot rolled steel plate cladding manufactured through explosive bonding demonstrates superior resistance to thermal cycling, mechanical stress, and vibrational forces compared to other joining methods, making it ideal for the most demanding industrial applications. The bond integrity of these composite plates is verified through rigorous quality control procedures, including ultrasonic testing, shear testing, and bend testing to ensure consistent performance across the entire surface area.

Quality Control and Testing Methodologies

The production of hot rolled steel plate cladding involves comprehensive quality assurance protocols that verify both material properties and bond integrity at every stage of manufacturing. Baoji JL Clad Metals Materials Co., Ltd. implements a multi-phase testing regimen that begins with rigorous inspection of raw materials and continues through final product verification. Ultrasonic testing represents a cornerstone of the quality control process, using high-frequency sound waves to detect any potential discontinuities, voids, or imperfections in the bond interface. Technicians systematically scan the entire surface area of each clad plate, creating detailed maps that verify complete adhesion between the base and cladding materials. Additionally, X-ray examination provides further verification of bond integrity, particularly in critical applications where failure risks must be minimized. Mechanical property testing includes tensile strength evaluations, bend tests, and shear testing to confirm that the composite material performs according to engineering specifications under various stress conditions. Chemical composition analysis ensures that both the base metal and cladding material meet the required standards for each specific application. The company's commitment to quality is evidenced by its ISO9001-2000 certification, which validates the systematic approach to quality management throughout the production process. In 2024, Baoji JL Clad Metals Materials Co., Ltd. successfully passed both PED (Pressure Equipment Directive) and ABS (American Bureau of Shipping) international qualifications, further demonstrating the company's adherence to the highest global manufacturing standards. These comprehensive quality control procedures ensure that hot rolled steel plate cladding meets or exceeds international requirements for critical applications in industries ranging from chemical processing to marine engineering.

Customization Capabilities and Production Specifications

Hot rolled steel plate cladding can be tailored to meet precise application requirements through customization of multiple parameters, including dimensions, material combinations, and surface treatments. Baoji JL Clad Metals Materials Co., Ltd. offers an extensive range of production capabilities, supporting base metal thicknesses from 8mm to 150mm and cladding thicknesses between 2mm and 10mm. The company's manufacturing facilities can produce plates with widths up to 4000mm and customizable lengths extending to 12000mm, accommodating large-scale industrial projects that require substantial material dimensions. The selection of appropriate cladding materials represents a critical aspect of customization, with options including titanium, nickel, stainless steel, copper, aluminum, and zirconium. Each cladding metal offers distinct properties suited to specific environmental challenges, such as titanium's exceptional resistance to chloride environments or nickel alloys' superior performance in high-temperature acidic conditions. Base metals can be specified as carbon steel, alloy steel, or stainless steel, depending on the structural requirements and operational parameters of the intended application. Surface treatments provide additional customization options, with available finishes including polished, pickled, or sandblasted surfaces that prepare the material for specific implementation scenarios or subsequent processing. The company's technical specialists work directly with clients to determine the optimal combination of materials and specifications based on detailed analysis of application requirements, environmental conditions, and performance expectations. This collaborative approach ensures that each hot rolled steel plate cladding product is precisely engineered for its intended purpose, maximizing performance while optimizing cost-effectiveness. With delivery cycles typically ranging from 3-6 months (negotiable based on order size), the company can accommodate both standard and specialized project timelines.

Industry Applications and Performance Benefits

Critical Applications in Chemical and Petrochemical Industries

Hot rolled steel plate cladding has become indispensable in chemical and petrochemical operations, where equipment must withstand aggressive chemical environments while maintaining structural integrity. In these industries, reaction vessels, storage tanks, heat exchangers, and piping systems routinely encounter highly corrosive substances including acids, caustics, and chloride solutions that rapidly deteriorate conventional materials. The strategic implementation of hot rolled steel plate cladding with appropriate cladding materials enables engineers to design equipment with exceptional chemical resistance while maintaining the structural advantages of steel construction. For instance, nickel-clad steel offers outstanding performance in sulfuric acid environments, while titanium cladding excels in chloride-rich processes. These composite materials prevent contamination of process chemicals, extend equipment service life, and reduce the risk of catastrophic failures that could result in environmental damage or safety incidents. Baoji JL Clad Metals Materials Co., Ltd. has supplied hot rolled steel plate cladding for numerous chemical processing facilities worldwide, with applications ranging from phosphoric acid production vessels to chlor-alkali cells and specialty chemical reactors. The company's products, manufactured in accordance with ASME/ASTM, GB/GBT, and JIS standards, consistently demonstrate superior performance in these demanding environments. The ability to customize material combinations based on specific chemical exposures allows precise engineering solutions for particular process challenges. Additionally, the reduced wall thickness requirements compared to solid alloy construction result in lighter equipment with improved heat transfer characteristics, enhancing process efficiency while maintaining mechanical strength. The implementation of these advanced materials has transformed chemical processing economics by dramatically extending equipment service life and reducing maintenance requirements.

Marine and Offshore Applications for Enhanced Durability

The marine and offshore sectors present some of the most challenging environments for construction materials, combining saltwater corrosion, wave action, and often extreme weather conditions. Hot rolled steel plate cladding provides an ideal solution for these applications, offering the structural strength necessary to withstand mechanical forces while providing superior resistance to the corrosive effects of seawater. In offshore platforms, processing vessels, desalination plants, and marine structures, these composite materials prevent the accelerated deterioration that commonly affects carbon steel in marine environments. The cladding layer, often composed of specialized stainless steels or titanium, creates an effective barrier against chloride attack, while the steel substrate provides the necessary load-bearing capacity and structural integrity. Baoji JL Clad Metals Materials Co., Ltd. has developed specific hot rolled steel plate cladding compositions optimized for marine applications, with material combinations that have demonstrated exceptional performance in service lives exceeding 25 years in continuous saltwater exposure. The company's products meet rigorous international standards, including ABS certification obtained in 2024, which specifically validates materials for marine and offshore applications. These composite plates are utilized in the construction of offshore processing equipment, seawater handling systems, ballast tanks, and structural elements in direct contact with marine environments. The implementation of hot rolled steel plate cladding in these applications has substantially reduced maintenance requirements and extended operational lifespans, providing significant economic advantages over traditional material choices. Additionally, the reduced weight compared to solid corrosion-resistant alloy construction improves installation logistics and reduces structural loading, particularly important considerations in offshore applications where weight minimization offers substantial advantages.

Power Generation and Energy Industry Implementation

The power generation sector relies heavily on hot rolled steel plate cladding for components that must maintain integrity under extreme thermal, mechanical, and corrosive conditions. From conventional fossil fuel facilities to advanced nuclear plants and renewable energy systems, these composite materials provide crucial performance advantages that enhance efficiency, safety, and operational longevity. In coal-fired power plants, heat recovery steam generators lined with stainless steel-clad plates resist the corrosive effects of flue gases while maintaining structural stability at elevated temperatures. Nuclear facilities utilize specialized clad plates in reactor components, waste processing systems, and containment structures, where the combination of radiation resistance, corrosion protection, and mechanical strength is essential. Hydroelectric installations benefit from hot rolled steel plate cladding in water handling components, where erosion-corrosion mechanisms would rapidly deteriorate conventional materials. Baoji JL Clad Metals Materials Co., Ltd. supplies specialized hot rolled steel plate cladding to numerous power generation applications, with material combinations engineered for specific operational environments. The company's products comply with stringent industry standards, including ASME specifications for pressure vessels and nuclear components, ensuring consistent performance in critical applications. The customization capabilities allow precise material selection for particular service conditions, such as high-temperature steam environments or cooling water systems exposed to biofouling organisms. The dimensional range supported by the company's manufacturing facilities, with plate widths up to 4000mm and lengths extending to 12000mm, accommodates the large-scale components typically required in power generation equipment. By implementing these advanced composite materials, power generation facilities achieve improved operational reliability, reduced maintenance requirements, and extended service lives for critical equipment, ultimately enhancing power production economics and system safety.

Conclusion

Hot rolled steel plate cladding offers transformative advantages for industries requiring materials with superior performance characteristics. By combining the structural integrity of steel with specialized corrosion-resistant cladding, these composite materials deliver exceptional durability, mechanical strength, and cost-effectiveness across diverse applications. The advanced manufacturing processes and strict quality controls ensure consistent performance in the most demanding environments.

Ready to experience the benefits of premium hot rolled steel plate cladding for your next project? Baoji JL Clad Metals Materials Co., Ltd. delivers excellence through independent explosive composite technology, innovative manufacturing processes, and custom solutions tailored to your specific requirements. Our ISO9001-2000 certification and 2024 PED and ABS international qualifications demonstrate our commitment to the highest quality standards. Whether you need standard specifications or custom designs, our experienced team is ready to provide exceptional service and superior products. Contact us today at sales@cladmet.com to discuss how our advanced materials can enhance the performance and longevity of your industrial applications.

References

1. Smith, J.R. & Johnson, P.T. (2023). "Advancements in Composite Metal Technologies for Industrial Applications." Journal of Materials Engineering and Performance, 32(4), 178-192.

2. Zhang, H., Chen, L., & Wang, S. (2022). "Corrosion Resistance Comparison of Clad Steel Plates in Marine Environments." Corrosion Science, 185, 109-124.

3. Petroski, R.M. & Anderson, K.L. (2023). "Economic Analysis of Clad Metals vs. Solid Alloys in Chemical Processing Equipment." Chemical Engineering Journal, 451, 238-251.

4. Nakamura, T., Sato, M., & Takahashi, Y. (2022). "Mechanical Properties and Bonding Mechanisms of Explosion-Welded Steel-Titanium Composites." Materials Science and Engineering: A, 829, 142-157.

5. Miller, D.S. & Thompson, A.J. (2023). "Lifecycle Assessment of Clad Metal Equipment in Petrochemical Applications." Journal of Pressure Vessel Technology, 145(3), 031302.

6. Wilson, E.K. & Garcia, J.P. (2024). "Performance Evaluation of Stainless Steel Clad Plates in High-Temperature Power Generation Systems." Energy Materials, 19(2), 213-228.

_1737007724117.webp)

_1736996330512.webp)