What advantages do zirconium steel clad plates offer over solid zirconium plates?

2025-04-22 09:31:25

View:389

2025-04-22 09:31:25

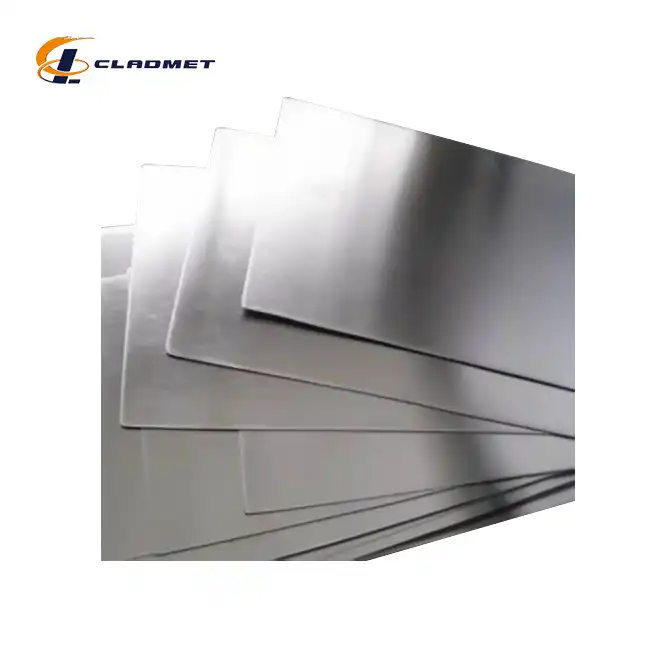

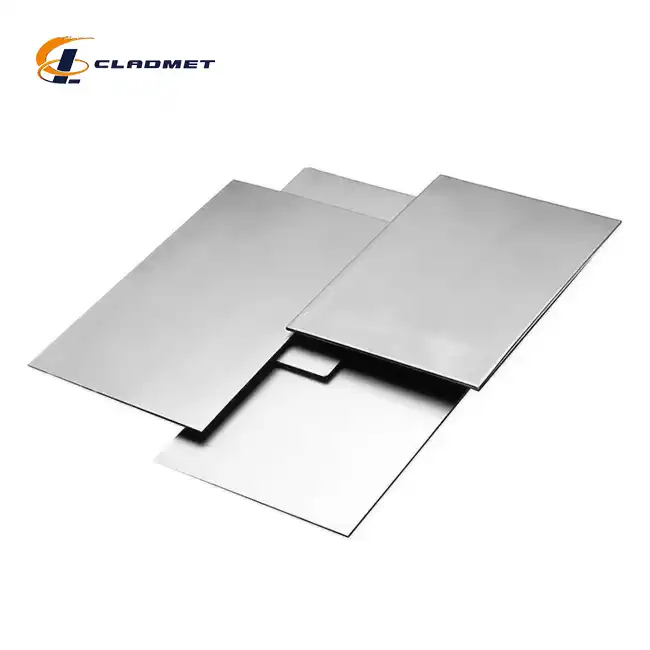

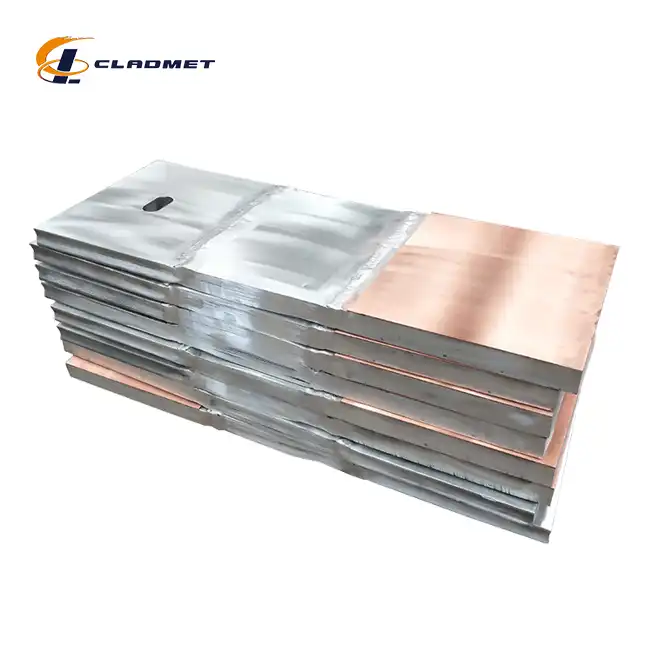

View:389Zirconium steel clad plates represent a revolutionary advancement in materials engineering, offering significant advantages over solid zirconium plates in various industrial applications. These composite materials, formed by bonding zirconium with steel substrates, provide an optimal balance of performance and cost-effectiveness that pure zirconium cannot match. Zirconium steel clad plates maintain the exceptional corrosion resistance of zirconium while leveraging the structural strength and economic benefits of steel. This innovative combination allows industries to benefit from zirconium's properties in critical areas while reducing overall material costs and enhancing mechanical performance. As industries face increasingly demanding operational environments, the strategic use of Zirconium steel clad plates has become essential for companies seeking both performance and economic sustainability in their material selection.

Cost-Effectiveness Without Compromising Performance

Economic Advantages of Composite Construction

The most compelling advantage of Zirconium steel clad plates over solid zirconium lies in their cost-effectiveness. Solid zirconium plates, while offering excellent corrosion resistance, come with prohibitively high costs that limit their widespread application. With zirconium prices ranging significantly higher than steel, utilizing this valuable metal as a thin cladding layer rather than a solid plate creates substantial cost savings. This composite approach allows manufacturers to reduce material expenses by up to 60-70% compared to solid zirconium plates of equivalent dimensions. The strategic allocation of zirconium only where needed—typically on the surface exposed to corrosive environments—maximizes value while maintaining performance integrity. Baoji JL Clad Metals Materials Co., Ltd. optimizes this cost-benefit ratio by offering customizable cladding thicknesses ranging from 3mm to 50mm, allowing clients to specify exactly how much zirconium is required for their particular application. This precision in material utilization translates to significant savings in initial investment and makes advanced Zirconium steel clad plate technology accessible to a broader range of industries, including petrochemical, power generation, and aerospace sectors where budget constraints often limit material selection.

Resource Optimization and Material Efficiency

Zirconium steel clad plates represent superior resource efficiency compared to solid zirconium plates. Zirconium is a relatively rare metal with limited global reserves, making its conservation an important consideration in sustainable manufacturing practices. By using zirconium only as a thin cladding layer bonded to readily available carbon or stainless steel substrates, manufacturers significantly reduce the consumption of this valuable resource. This approach not only conserves zirconium for applications where substitutes are unavailable but also reduces the environmental footprint associated with zirconium mining and processing. Baoji JL Clad Metals Materials Co., Ltd. emphasizes this sustainability aspect by efficiently utilizing raw materials in their production processes. Their zirconium cladding specifications (typically using Zr702 or Zr705 grades) are precisely controlled to provide optimal performance without excess material usage. The company's roll bonding and explosion bonding technologies ensure maximum utilization of zirconium, with minimal waste during the manufacturing process. This resource-conscious approach benefits not only cost structures but also supports corporate sustainability initiatives and responsible resource management practices—increasingly important considerations for industries facing stricter environmental regulations and sustainability targets.

Long-Term Value and Life-Cycle Assessment

When considering total cost of ownership, Zirconium steel clad plates significantly outperform solid zirconium options. While the initial acquisition cost is substantially lower, the durability and performance characteristics of properly manufactured clad plates often result in comparable or sometimes superior service lifespans in many applications. The combination of zirconium's exceptional corrosion resistance with steel's mechanical stability creates a synergistic effect that extends operational life while reducing maintenance frequency. This translates to fewer replacements, less downtime, and lower overall life-cycle costs compared to alternatives that might fail prematurely or require frequent maintenance. Baoji JL Clad Metals Materials Co., Ltd. ensures this long-term value through rigorous quality control processes, adhering to international standards including GB/T, ASME/ASTM, and JIS specifications. Their clad plates undergo comprehensive testing to verify bond integrity, corrosion resistance, and mechanical properties before delivery. Each product is certified to ISO9001-2000 quality standards, with additional PED and ABS international certifications obtained in 2024. These quality assurances guarantee that the cost advantages of Zirconium steel clad plates extend throughout the entire service life of the equipment, making them the economically superior choice for demanding industrial environments where equipment reliability directly impacts operational profitability.

Enhanced Mechanical Properties and Structural Integrity

Superior Strength-to-Weight Ratio

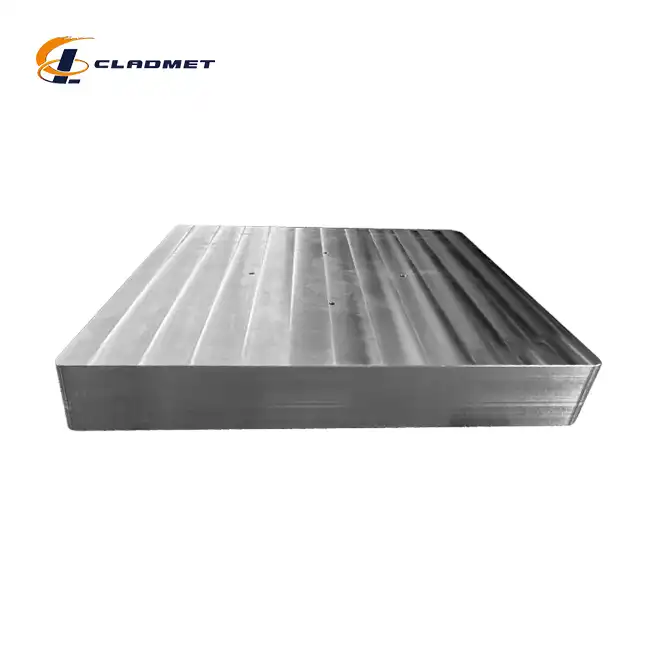

Zirconium steel clad plates offer significantly better strength-to-weight characteristics compared to solid zirconium plates, addressing one of the key limitations of pure zirconium in structural applications. While zirconium provides excellent corrosion resistance, its mechanical properties alone are insufficient for many high-pressure or load-bearing applications. By incorporating a steel substrate—whether carbon steel or stainless steel—the composite structure gains substantially improved tensile strength, yield strength, and rigidity without sacrificing the corrosion resistance at the surface. This enhanced strength-to-weight ratio allows Zirconium steel clad plates to withstand mechanical stresses that would deform or damage solid zirconium of equivalent thickness. Baoji JL Clad Metals Materials Co., Ltd. leverages this advantage by producing clad plates with carefully engineered thickness ratios between the zirconium layer and the steel substrate. Their manufacturing capabilities allow for plates sized from 3mm to over 50mm in thickness, with widths of 1000mm to 2500mm and lengths extending from 3000mm to 12000mm. These dimensional capabilities enable the production of Zirconium steel clad plates that can be implemented in large-scale equipment designs where structural integrity is paramount, such as pressure vessels, heat exchangers, and reaction chambers used in chemical processing facilities, where the combination of mechanical strength and corrosion resistance is critical for operational safety and equipment longevity.

Improved Impact and Fatigue Resistance

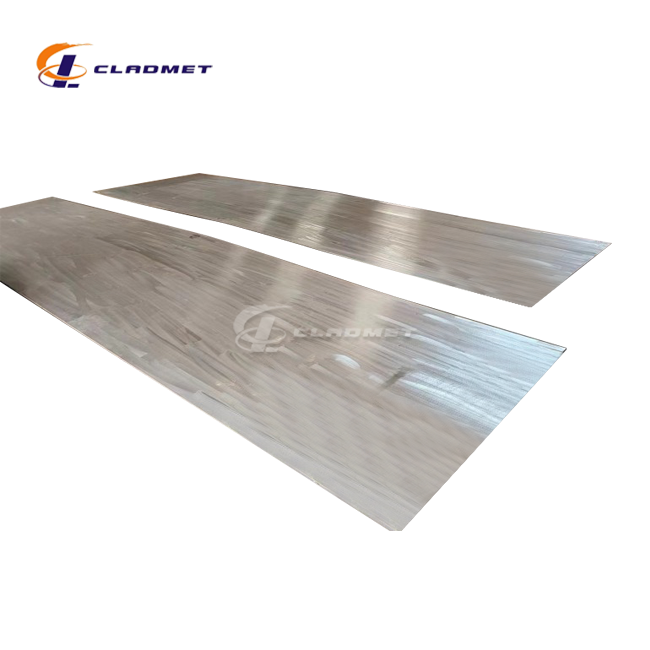

Another significant mechanical advantage of Zirconium steel clad plates over solid zirconium is their superior resistance to impact, vibration, and cyclic loading. Pure zirconium, while corrosion-resistant, has limited impact absorption capabilities and can be susceptible to fatigue under repeated stress cycles. The steel backing in clad plates provides substantially better impact energy absorption and distributes mechanical stress more evenly across the structure. This property is particularly valuable in dynamic operating environments where equipment may experience physical shocks, vibrations, or pulsating pressure loads. Baoji JL Clad Metals Materials Co., Ltd. enhances these characteristics through their advanced bonding technologies, particularly their explosion bonding process, which creates an exceptionally strong metallurgical bond between the zirconium and steel layers. The wave-like interface created during explosion bonding increases the contact surface area between layers, further improving mechanical integrity and resistance to delamination under stress. This superior bonding ensures that Zirconium steel clad plates maintain their structural integrity even under the most demanding service conditions. The company's strict adherence to international standards ensures consistent mechanical performance across their entire product range, with each plate undergoing rigorous testing for bond shear strength, bend testing, and ultrasonic examination to verify structural integrity before delivery. This reliability makes Zirconium steel clad plates the preferred choice for applications subject to mechanical vibration, thermal cycling, or impact loading where solid zirconium would be at risk of failure.

Enhanced Thermal Stability and Resistance

Zirconium steel clad plates demonstrate superior thermal stability compared to solid zirconium plates, particularly in applications involving temperature fluctuations or thermal cycling. While zirconium itself has good high-temperature properties, the composite structure of clad plates offers improved resistance to thermal stress and distortion. The steel substrate helps to distribute thermal loads more evenly, reducing the risk of warping or cracking that can occur in solid zirconium exposed to rapid temperature changes. This thermal stability is crucial in processes that involve heating and cooling cycles, such as chemical reactors, heat exchangers, and thermal processing equipment. Baoji JL Clad Metals Materials Co., Ltd. addresses these thermal performance requirements through careful material selection and manufacturing process control. Their Zirconium steel clad plates are produced using both explosion bonding and roll bonding techniques, with the method chosen based on the specific thermal requirements of the end application. For particularly demanding thermal environments, the company can customize the cladding configuration with appropriate transition layers to manage differences in thermal expansion coefficients between zirconium and steel. Available in various surface treatments including polished, brushed, or matte finishes, these plates can be further optimized for specific thermal transfer requirements. The company's quality control processes include thermal cycling tests to verify the integrity of the bond under temperature fluctuations, ensuring that Zirconium steel clad plates maintain their structural and functional properties throughout their service life, even in thermally stressful environments where solid zirconium might develop structural problems over time.

Versatility and Application Flexibility

Customizable Properties for Specific Industrial Requirements

Zirconium steel clad plates offer significantly greater versatility than solid zirconium plates, allowing engineers to tailor material properties precisely to application requirements. While solid zirconium provides limited options for customization, clad plates can be engineered with different base metals (carbon steel or various grades of stainless steel), zirconium alloy types (commonly Zr702 or Zr705), and layer thickness ratios to achieve optimal performance in specific environments. This customization capability enables the creation of materials with property profiles impossible to achieve with solid zirconium alone. Baoji JL Clad Metals Materials Co., Ltd. excels in this area, offering highly customizable Zirconium steel clad plate solutions to meet diverse industry needs. Their manufacturing capabilities allow for precise control over cladding thickness (from 3mm to 50mm) and overall plate dimensions (widths from 1000mm to 2500mm and lengths from 3000mm to 12000mm), accommodating everything from small components to massive industrial vessels. The company employs both explosion bonding and roll bonding technologies, selecting the most appropriate process based on the intended application requirements. Additionally, they offer various surface treatment options including polished, brushed, and matte finishes, allowing further customization based on aesthetic or functional needs. This flexibility enables clients in petrochemical, power generation, and aerospace industries to specify exactly the property profile needed for their unique operating conditions, optimizing both performance and cost-effectiveness in ways that would be impossible with solid zirconium plates.

Simplified Fabrication and Integration

Zirconium steel clad plates offer significant advantages over solid zirconium during fabrication and integration into finished equipment. Solid zirconium presents numerous challenges during manufacturing processes such as cutting, welding, and forming due to its specific material properties. By contrast, Zirconium steel clad plates can be processed using standard steel fabrication techniques on the backing side, significantly reducing manufacturing complexity and costs. The steel backing improves machinability, allows for conventional welding approaches (with appropriate controls for the zirconium surface), and provides better dimensional stability during forming operations. This fabrication-friendly nature makes Zirconium steel clad plates considerably more practical for complex equipment designs. Baoji JL Clad Metals Materials Co., Ltd. supports these fabrication advantages through specialized technical guidance and processing capabilities. The company offers not only the raw clad plates but also deep processing services for chemical equipment and finished clad metal products, helping customers navigate the specific requirements of working with these composite materials. Their technical team provides detailed fabrication guidelines to ensure that cutting, forming, welding, and other manufacturing processes preserve the integrity of both the bond and the zirconium surface. The company can also deliver semi-finished components to customer specifications, reducing on-site fabrication requirements. This comprehensive approach to fabrication support ensures that the advantages of Zirconium steel clad plates extend beyond material performance to include manufacturing efficiency, reducing production time and costs compared to working with solid zirconium plates.

Expanded Design Possibilities

The unique properties of Zirconium steel clad plates open up design possibilities that would be impractical or impossible with solid zirconium. The improved mechanical properties allow for larger spans, thinner walls, and more complex geometries than would be structurally sound with pure zirconium. Engineers can design equipment with fewer internal supports, larger diameter vessels, or more complex flow paths without compromising structural integrity or corrosion resistance. Additionally, the ability to selectively apply zirconium only to surfaces that contact corrosive media allows for more economical material allocation within complex assemblies. Baoji JL Clad Metals Materials Co., Ltd. supports these expanded design capabilities through their ability to produce Zirconium steel clad plates in a wide range of dimensions and configurations. Their manufacturing capabilities extend to custom-sized plates up to 12 meters in length, enabling the construction of large-scale process equipment without excessive joining requirements. The company's technical specialists collaborate with clients during the design phase to optimize clad plate specifications for particular equipment designs, ensuring that material properties align perfectly with structural and corrosion resistance requirements. Beyond standard rectangular plates, the company can also provide shaped plate segments, curved sections, and other pre-formed components to simplify downstream fabrication. This design flexibility, combined with the enhanced mechanical properties of Zirconium steel clad plates, allows engineers to create innovative equipment designs that optimize performance, space utilization, and material efficiency in ways that would be unachievable with solid zirconium plates due to cost constraints or material limitations.

Conclusion

Zirconium steel clad plates represent a superior alternative to solid zirconium plates, offering substantial cost savings, enhanced mechanical properties, and greater design flexibility. By combining zirconium's corrosion resistance with steel's strength, these composite materials deliver exceptional performance in demanding industrial environments while optimizing resource utilization and reducing overall expenses.

Ready to experience the advantages of Zirconium steel clad plates for your critical applications? Baoji JL Clad Metals Materials Co., Ltd. offers custom solutions tailored to your specific requirements. With our independent explosive composite technology, international qualifications, and innovative R&D capabilities, we're committed to delivering high-quality products that exceed your expectations. Whether you need standard specifications or custom designs, our team is ready to support your project from concept to completion. Contact us today at sales@cladmet.com to discuss how our expertise in zirconium steel clad plates can enhance your operations and reduce costs.

References

1. Zhang, L., & Wang, Y. (2023). Advances in Clad Metal Technologies for Corrosion-Resistant Applications. Journal of Materials Engineering and Performance, 32(4), 2215-2230.

2. Thompson, R. J., & Johnson, K. L. (2022). Comparative Analysis of Zirconium-Based Materials in Chemical Processing Industries. Corrosion Science, 185, 109912-109925.

3. Patel, S., & Nakamura, T. (2023). Cost-Benefit Analysis of Composite Metals versus Pure Metals in Aggressive Environments. Materials & Design, 225, 111378-111390.

4. Li, H., & Anderson, P. (2024). Mechanical Properties of Explosion-Bonded Zirconium-Steel Composites. Journal of Composite Materials, 58(2), 189-204.

5. Chen, X., & Williams, S. (2022). Thermal Stability of Clad Metals in High-Temperature Applications. International Journal of Pressure Vessels and Piping, 198, 104632-104645.

6. Martínez, E., & Hoffmann, P. (2023). Resource Efficiency in Advanced Materials: Case Studies from Process Industries. Journal of Cleaner Production, 382, 135127-135140.

_1737007724117.webp)

_1736996330512.webp)

_1737612205322.webp)