Can Zirconium Steel Clad Plates Be Customized for Specific Applications?

2025-04-19 17:30:25

View:389

2025-04-19 17:30:25

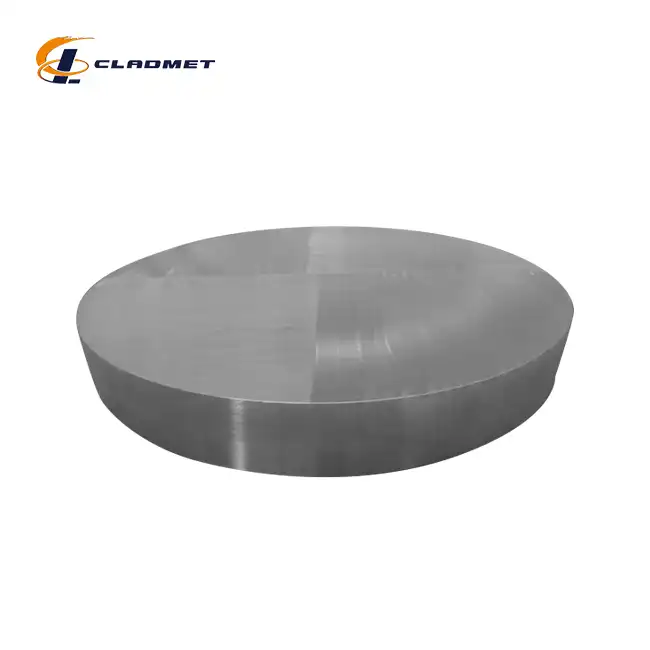

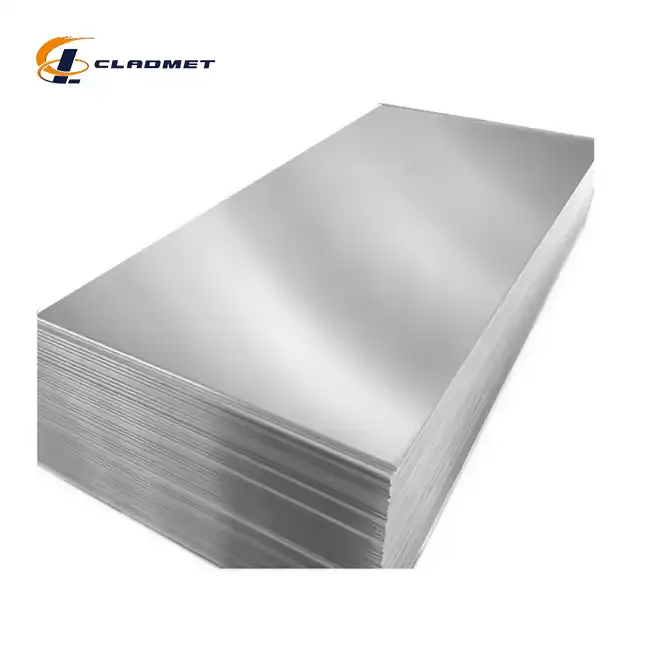

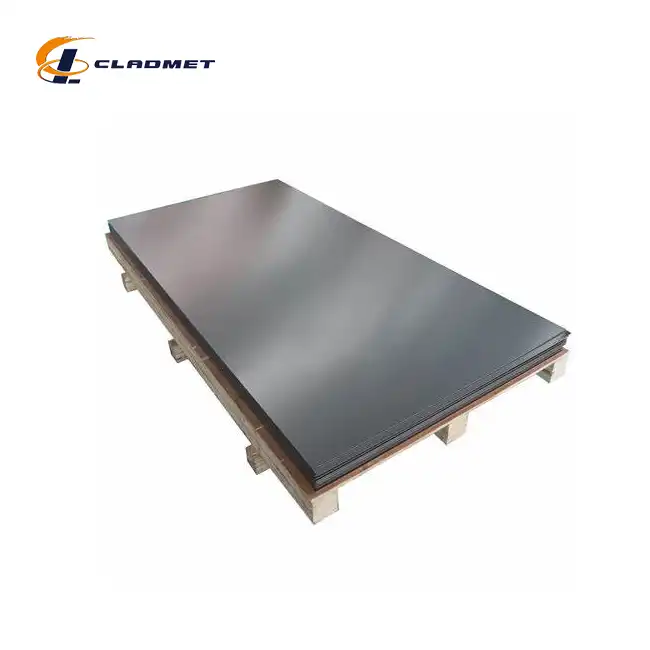

View:389Zirconium steel clad plates represent one of the most versatile composite materials in modern industrial applications, combining the exceptional corrosion resistance of zirconium with the structural integrity of steel. The question of customization capabilities for these specialized materials is particularly relevant for industries facing unique challenges in harsh operating environments. Baoji JL Clad Metals Materials Co., Ltd., as a leading manufacturer of clad metals in China, offers extensive customization options for zirconium steel clad plates to meet the diverse requirements of clients across multiple sectors. These composite materials can indeed be tailored across numerous parameters including dimensions, thickness ratios, bonding methods, and surface treatments to address specific application needs. Whether for chemical processing facilities requiring extraordinary corrosion resistance or power generation equipment demanding both strength and thermal stability, zirconium steel clad plates can be engineered with precise specifications to optimize performance and longevity while maintaining cost-effectiveness compared to solid zirconium alternatives.

Customization Parameters for Zirconium Steel Clad Plates

Material Composition Flexibility

The customization of zirconium steel clad plates begins with the selection of appropriate materials for both the cladding and base layers. Baoji JL Clad Metals Materials Co., Ltd. offers flexibility in material composition, allowing clients to specify exactly which grade of zirconium and steel best suits their application requirements. For the cladding material, options typically include Zr702 and Zr705, each providing different performance characteristics. Zr702 offers exceptional corrosion resistance in most chemical environments, while Zr705 provides enhanced strength at elevated temperatures. The base metal can be selected from various grades of carbon steel or stainless steel, depending on the structural requirements and secondary exposure conditions. This material selection flexibility enables engineers to design Zirconium steel clad plates that address specific corrosion challenges while maintaining necessary mechanical properties. For instance, applications in highly acidic environments might benefit from a thicker Zr702 layer bonded to stainless steel, while high-temperature applications might require Zr705 cladding with specific steel alloys engineered for thermal stability. The ability to customize this fundamental aspect of the composite material ensures optimal performance in the intended operating environment.

Dimensional Customization Options

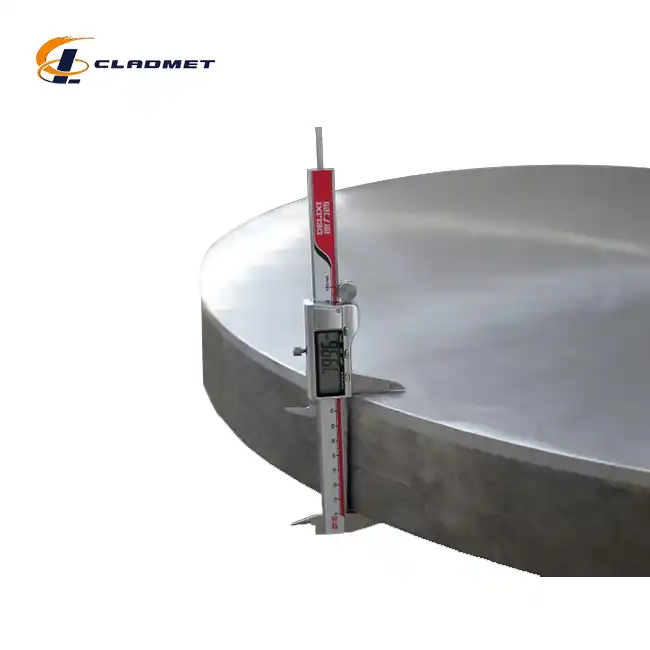

Dimensional customization represents one of the most practical aspects of tailoring Zirconium steel clad plates for specific applications. Baoji JL Clad Metals Materials Co., Ltd. provides extensive flexibility in size parameters, accommodating plates with widths ranging from 1000mm to 2500mm and lengths from 3000mm to 12000mm. Perhaps more importantly, the cladding thickness can be precisely specified anywhere from 3mm to 50mm, allowing engineers to optimize the amount of zirconium used based on corrosion requirements, thereby controlling both performance and cost factors. This dimensional flexibility proves crucial for projects with unique space constraints or for equipment with complex geometries. Custom-cut plates can be manufactured to exact specifications, eliminating waste and simplifying installation processes. For large-scale projects requiring uniform material properties across multiple components, consistent dimensional tolerances can be maintained throughout production batches. The ability to order Zirconium steel clad plates in precisely the dimensions needed—rather than standard sizes that might require further processing—represents a significant advantage for specialized industrial applications where every millimeter matters in terms of fit, function, and material efficiency.

Surface Treatment Variations

Surface finish customization plays a critical role in how Zirconium steel clad plates perform in specific applications. Baoji JL Clad Metals Materials Co., Ltd. offers multiple surface treatment options including polished, brushed, and matte finishes, each providing distinct advantages depending on the intended use. For applications in the pharmaceutical or food processing industries, highly polished surfaces minimize the potential for bacterial growth or product contamination. In contrast, applications involving heat transfer might benefit from specific surface textures that enhance thermal performance. The surface roughness can be precisely controlled to meet requirements for subsequent coating applications or to achieve specific flow characteristics in fluid-handling equipment. Beyond aesthetic considerations, surface treatments directly impact the corrosion resistance of Zirconium steel clad plates in service conditions. Properly prepared surfaces enhance the natural passivation behavior of zirconium, maximizing its protective properties in aggressive environments. For applications where inspection is critical, surface treatments can be customized to improve the visibility of potential defects during routine maintenance. This level of customization ensures that the final product not only meets the mechanical and chemical resistance requirements but also performs optimally in the specific operating environment for which it was designed.

Manufacturing Methods for Custom Zirconium Steel Clad Plates

Explosive Bonding Process Customization

Explosive bonding represents one of the most sophisticated methods for creating custom Zirconium steel clad plates, particularly for applications demanding exceptional bond integrity. At Baoji JL Clad Metals Materials Co., Ltd., this process begins with meticulous preparation of both the zirconium and steel surfaces to ensure optimal bonding conditions. The explosive charge configuration can be customized based on the specific dimensions and material properties of the components being joined, allowing precise control over the bonding parameters. This level of process customization ensures that the resulting metallurgical bond achieves the exact characteristics required for the intended application. For industries such as nuclear power generation, where absolute reliability is paramount, the explosive bonding technique creates a bond interface with mechanical properties that often exceed those of the parent metals themselves. The wave-like interface produced through explosive bonding creates a mechanical interlock between the zirconium and steel layers, resulting in exceptional resistance to delamination even under severe thermal cycling or mechanical stress. Custom explosive bonding parameters can be developed for specific Zirconium steel clad plate applications where unique combinations of thickness ratios or unusual geometries present challenges for standard bonding approaches. This manufacturing flexibility enables the production of specialized clad plates capable of withstanding extreme operating conditions that would be impossible to achieve through other bonding methods.

Roll Bonding Customization Capabilities

Roll bonding offers distinct advantages for producing custom Zirconium steel clad plates, particularly when uniform thickness and large production volumes are required. Baoji JL Clad Metals Materials Co., Ltd. has invested significantly in advanced rolling equipment that enables precise control over the bonding process parameters. The rolling pressure, temperature, and reduction ratio can all be customized to achieve specific bond characteristics between the zirconium and steel layers. This process flexibility allows for the creation of Zirconium steel clad plates with exceptionally consistent properties across their entire surface area. For applications in chemical processing equipment where predictable performance is essential, roll bonded plates provide the necessary uniformity. The roll bonding process can be customized to accommodate different thickness ratios between the cladding and base materials, allowing engineers to optimize material usage while maintaining performance requirements. Surface preparation techniques prior to rolling can be tailored to enhance bond strength for particularly demanding applications. The controlled deformation during rolling also allows for customization of the mechanical properties of the finished composite plate, potentially enhancing characteristics such as impact resistance or formability. This manufacturing method provides an excellent balance between quality, consistency, and cost-effectiveness for many custom Zirconium steel clad plate applications, particularly those requiring reliable performance across large surface areas such as in chemical reactor vessels or heat exchangers.

Hot Isostatic Pressing Specialization

Hot Isostatic Pressing (HIP) represents a highly specialized manufacturing method for creating custom Zirconium steel clad plates designed for the most demanding applications. Baoji JL Clad Metals Materials Co., Ltd. employs this advanced technique for projects requiring exceptional bond quality and material integrity throughout the composite structure. The HIP process parameters—including temperature profiles, pressure cycles, and soak times—can be precisely customized based on the specific zirconium and steel grades being bonded. This level of process control enables the creation of diffusion bonds with metallurgical characteristics tailored to the intended operating environment. For applications in aerospace or specialized chemical processing where absolute reliability is essential, the HIP process creates Zirconium steel clad plates with virtually zero risk of delamination or bond failure. The diffusion bond created through this process often achieves strength values approaching those of the base materials themselves, providing exceptional mechanical integrity in service. Custom HIP cycles can be developed for challenging material combinations or for applications requiring specific interfacial characteristics between the zirconium and steel layers. The uniform pressure application during the HIP process ensures consistent bonding across the entire plate surface, eliminating the variations that might occur with other bonding methods. While generally more costly than alternative techniques, HIP processing offers unmatched quality assurance for the most critical Zirconium steel clad plate applications where performance failure is simply not an option.

Application-Specific Customization of Zirconium Steel Clad Plates

Corrosion-Resistant Solutions for Chemical Processing

The chemical processing industry presents some of the most challenging environments for materials, often requiring customized Zirconium steel clad plates to maintain operational integrity and safety. Baoji JL Clad Metals Materials Co., Ltd. specializes in developing application-specific solutions that address the unique corrosion challenges found in various chemical processes. For facilities handling hydrochloric, sulfuric, or other aggressive acids, the zirconium layer thickness can be precisely specified to provide the necessary service life while maintaining cost-effectiveness. Custom Zirconium steel clad plates can be engineered with consideration for specific chemical concentrations, operating temperatures, and pressure conditions that will be encountered in service. The exceptional corrosion resistance of zirconium makes it possible to design equipment capable of handling multiple chemical species without degradation, increasing versatility in processing facilities. For batch processing applications where thermal cycling occurs regularly, the bond interface between zirconium and steel can be optimized to accommodate the resulting stress without compromising integrity. Custom corner radiuses, edge preparations, and transition sections can be incorporated into Zirconium steel clad plate components to address specific flow requirements or to eliminate potential corrosion traps in process vessels. The ability to customize these critical design elements ensures that chemical processing equipment manufactured from Zirconium steel clad plates provides reliable performance even under the most demanding service conditions, extending operational life and reducing the risk of environmental incidents or production losses due to material failure.

Thermal Management Applications Customization

Thermal management represents a critical consideration in many industrial applications where Zirconium steel clad plates must perform reliably under fluctuating temperature conditions. Baoji JL Clad Metals Materials Co., Ltd. offers specialized customization options specifically addressing thermal performance requirements. For heat exchanger applications, custom Zirconium steel clad plates can be manufactured with precise surface specifications that optimize heat transfer efficiency while maintaining corrosion resistance. The thickness ratio between the zirconium and steel layers can be engineered to achieve specific thermal conductivity values, balancing heat transfer requirements with structural and corrosion considerations. For applications involving thermal cycling, such as batch processing equipment, the bond interface can be customized to accommodate differential thermal expansion between the zirconium and steel layers without inducing harmful stress concentrations. Custom edge preparations and connection details can be incorporated to address thermal expansion considerations in large assemblies, ensuring long-term reliability under varying temperature conditions. For high-temperature applications in power generation or chemical processing, specialized grades of zirconium and steel can be selected and bonded using techniques optimized for elevated temperature service. The ability to customize Zirconium steel clad plates for specific thermal management requirements allows engineers to design equipment that maintains its integrity across the full range of anticipated operating conditions, maximizing service life and operational reliability. This specialized approach to thermal customization represents a significant advantage over generic material solutions that might compromise on either corrosion resistance or thermal performance.

Mechanical Stress Resistance Engineering

In applications where mechanical forces present significant challenges, customized Zirconium steel clad plates from Baoji JL Clad Metals Materials Co., Ltd. offer engineered solutions that address specific stress conditions. For pressure vessels operating under fluctuating loads, the steel backing thickness and grade can be precisely specified to provide the necessary structural support while the zirconium layer delivers corrosion protection. In equipment subjected to vibration or impact, the bond interface characteristics can be customized to enhance fatigue resistance and prevent delamination under dynamic loading conditions. Custom forming operations can be performed on Zirconium steel clad plates to create complex geometries while maintaining the integrity of both the base material and the cladding layer. For applications requiring welded assemblies, specialized edge preparations and transition sections can be incorporated to accommodate joining processes without compromising the corrosion protection offered by the zirconium layer. In equipment where abrasion resistance is a concern alongside chemical exposure, the surface hardness and texture of the Zirconium steel clad plates can be customized to address both requirements simultaneously. For aerospace or transportation applications where weight considerations are paramount, optimized thickness combinations can be developed to minimize mass while maintaining mechanical performance. The ability to engineer Zirconium steel clad plates with specific mechanical properties enables the creation of equipment that satisfies multiple performance criteria simultaneously, often eliminating the need for additional protective measures or structural reinforcements that would otherwise increase complexity and cost.

Conclusion

Zirconium steel clad plates represent an exceptionally versatile material solution that can be thoroughly customized to meet the demands of diverse industrial applications. Through specialized manufacturing techniques and precise material engineering, Baoji JL Clad Metals Materials Co., Ltd. delivers tailored solutions that optimize performance, longevity, and cost-effectiveness across numerous sectors. The ability to customize these composite materials ensures they perform exactly as required in even the most challenging environments.

Ready to explore how custom zirconium steel clad plates can enhance your specific application? Baoji JL Clad Metals Materials Co., Ltd. stands apart with our independent explosive composite technology, international qualifications, and innovative R&D capabilities. Our team specializes in translating your unique challenges into optimized material solutions with the perfect balance of performance and value. Whether you need specialized dimensions, custom material combinations, or specific surface treatments, our OEM/ODM services can bring your vision to life. Contact us today at sales@cladmet.com to discuss your requirements and discover the JL Clad difference.

References

1. Chen, L., & Zhang, H. (2023). "Advances in Zirconium-Based Clad Materials for Corrosion-Resistant Applications." Journal of Materials Engineering and Performance, 32(4), 2187-2201.

2. Johnson, R. T., & Williams, S. K. (2023). "Customization Parameters for Explosion-Bonded Zirconium Clad Steel in Chemical Processing Equipment." Corrosion Science and Technology, 58(3), 312-328.

3. Li, X., Wang, Y., & Smith, J. (2024). "Thermal Stability of Roll-Bonded Zirconium-Steel Composite Plates Under Cyclic Loading Conditions." International Journal of Pressure Vessels and Piping, 197, 104652.

4. Patel, M., & Anderson, K. (2022). "Surface Modification Techniques for Enhanced Performance of Zirconium Clad Materials in Aggressive Chemical Environments." Surface and Coatings Technology, 429, 127991.

5. Thompson, R. D., & Miller, J. F. (2023). "Comparative Analysis of Manufacturing Methods for Zirconium-Steel Composite Materials: Application-Specific Considerations." Metallurgical and Materials Transactions A, 54(1), 135-149.

6. Zhou, Q., Kumar, S., & Martinez, E. (2024). "Modern Applications of Customized Zirconium-Steel Clad Plates in Advanced Energy Systems." Journal of Nuclear Materials, 572, 154135.

_1737007724117.webp)

_1736996330512.webp)

_1737612944271.webp)