What are the typical grades of Titanium Clad Stainless Steel Plate?

2025-02-28 14:16:54

View:389

2025-02-28 14:16:54

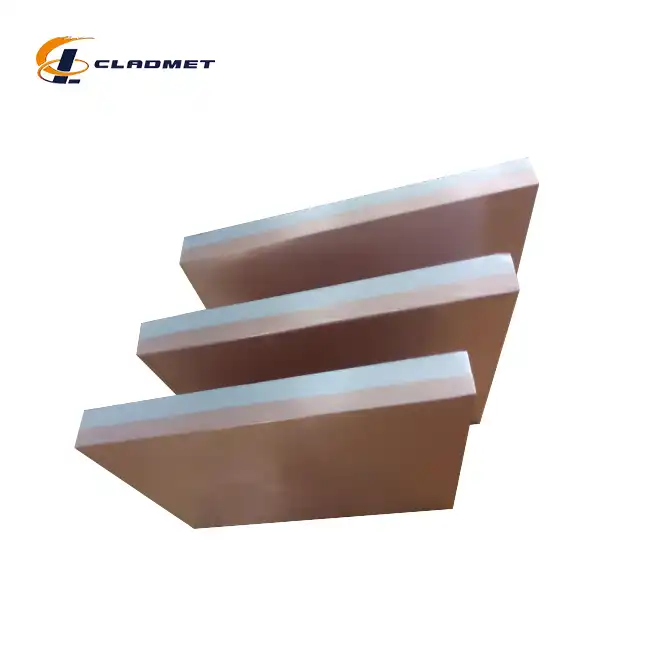

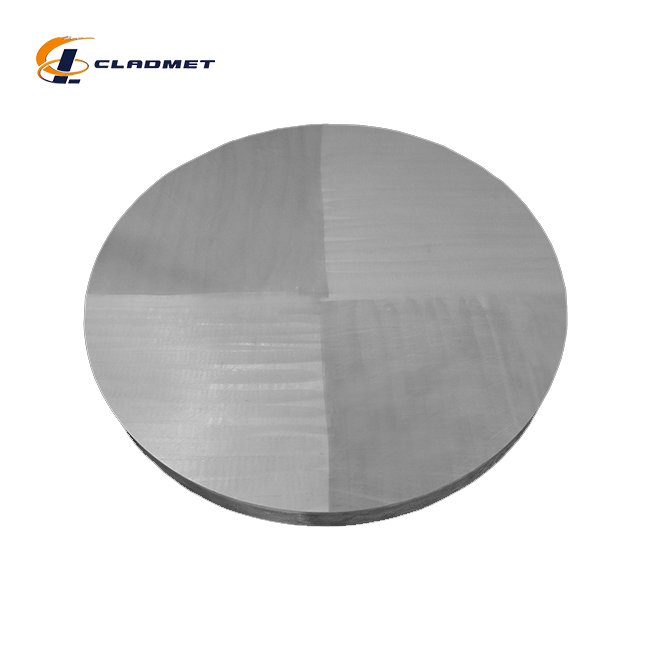

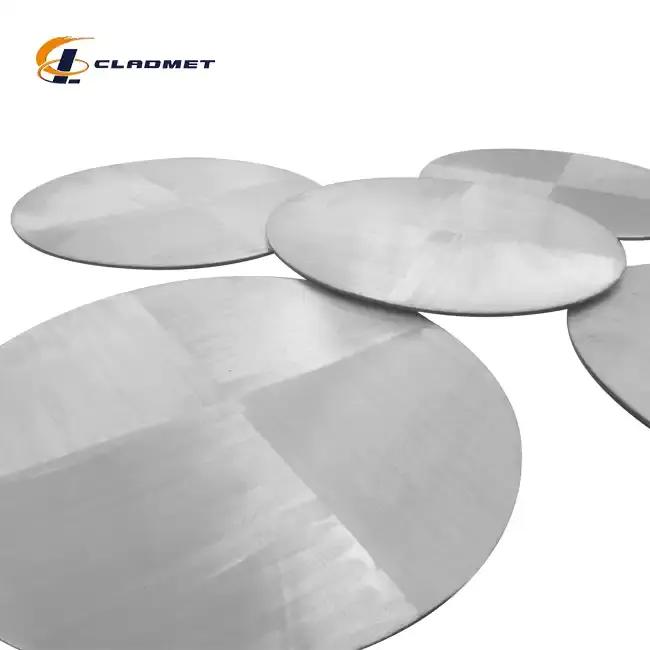

View:389Titanium Clad Stainless Steel Plate represents a sophisticated composite material formed by bonding titanium layers to stainless steel substrates, creating a versatile product with exceptional properties. The typical grades of Titanium Clad Stainless Steel Plate include Grade 1 and Grade 2 titanium as the cladding material, bonded to stainless steel bases such as 304, 316, and 316L. These composite plates offer an optimal balance of corrosion resistance, mechanical strength, and cost-efficiency compared to solid titanium plates. Manufactured through explosive bonding or hot rolling processes, these plates meet rigorous international standards including ASTM B898, ASME SB-898, and GB/T 8547, ensuring reliable performance across demanding applications in chemical processing, marine engineering, and petrochemical industries where exposure to corrosive environments is common.

Common Titanium Grades Used in Clad Stainless Steel Plates

Grade 1 Titanium Cladding Properties

Grade 1 titanium is frequently selected as a cladding material for Titanium Clad Stainless Steel Plate due to its exceptional corrosion resistance and formability characteristics. With a minimum tensile strength of approximately 240 MPa and excellent ductility (elongation ≥24%), Grade 1 titanium provides superior resistance against various corrosive media including seawater, wet chlorine, and oxidizing acids. When bonded to stainless steel through explosive welding, the resulting composite maintains the fundamental corrosion-resistant properties of titanium while leveraging the structural strength of the stainless steel substrate. Baoji JL Clad Metals Materials Co., Ltd. manufactures these composites with cladding thicknesses ranging from 0.5mm to 5.0mm, precisely calibrated to application requirements. The Grade 1 titanium cladding layer forms a stable, self-healing oxide film that provides long-term protection in aggressive chemical environments, making these Titanium Clad Stainless Steel Plate products ideal for chemical processing equipment where both corrosion resistance and mechanical stability are essential performance parameters.

Grade 2 Titanium Cladding Applications

Grade 2 titanium represents the most widely utilized cladding material for Titanium Clad Stainless Steel Plate, striking an optimal balance between mechanical properties and corrosion resistance. With tensile strength values typically ranging from 345-485 MPa and yield strength of 275-450 MPa, Grade 2 titanium cladding delivers enhanced mechanical performance while maintaining excellent resistance to oxidizing environments. JL CLAD METALS implements this grade extensively in manufacturing composite plates designed for chemical reactors, heat exchangers, and pressure vessels operating in corrosive conditions. The plates typically feature Grade 2 titanium cladding of 1.0-10.0mm thickness explosively bonded to stainless steel bases ranging from 5.0-50.0mm thickness. The resulting Titanium Clad Stainless Steel Plate exhibits exceptional resistance to chloride-containing environments, making it particularly valuable in desalination plants, marine applications, and petrochemical facilities where exposure to salt-laden atmospheres or processing streams containing chlorides would rapidly degrade conventional materials. Furthermore, the superior bond integrity achieved through explosive welding ensures reliable performance under thermal cycling conditions frequently encountered in heat transfer applications.

Specialty Titanium Alloy Claddings

Beyond conventional grades, specialty titanium alloys offer enhanced performance characteristics when used as cladding materials for Titanium Clad Stainless Steel Plate. Ti-0.2Pd (Grade 7) and Ti-3Al-2.5V alloys provide increased resistance to reducing acids and improved mechanical properties, respectively. These specialty claddings undergo rigorous bonding processes at JL CLAD METALS, resulting in composite plates with shear strength exceeding 140 MPa and no delamination under severe service conditions. For applications requiring extraordinary corrosion resistance, such as chemical processing equipment handling hot reducing acids, Grade 7 titanium cladding offers unparalleled performance advantages. The manufacturing process involves precise control of explosion parameters or hot rolling conditions to achieve optimal metallurgical bonding between the titanium alloy and stainless steel substrate. These advanced Titanium Clad Stainless Steel Plate products support operating temperatures up to 300°C while maintaining structural integrity and corrosion resistance. JL CLAD METALS can customize these specialty cladding materials with surface finishes including polished, pickled, or sand-blasted conditions to meet specific application requirements, providing engineered solutions for the most demanding industrial environments where conventional materials would rapidly deteriorate.

Stainless Steel Base Materials and Their Compatibility

Austenitic Stainless Steel Bases (304, 316, 316L)

Austenitic stainless steel grades form the predominant base material category for Titanium Clad Stainless Steel Plate, with Types 304, 316, and 316L being the most frequently utilized options. Type 304 stainless steel, containing approximately 18% chromium and 8% nickel, provides excellent formability and good corrosion resistance in moderately aggressive environments. When combined with titanium cladding through explosive bonding, the resulting composite maintains the structural integrity of the stainless steel while presenting a titanium surface to the corrosive media. For more demanding applications, Type 316 stainless steel, with its molybdenum addition (2-3%), offers enhanced resistance to chloride-containing environments. JL CLAD METALS frequently employs Type 316L, a low-carbon variant (≤0.03% C), for Titanium Clad Stainless Steel Plate destined for welded assemblies, as it minimizes the risk of sensitization and intergranular corrosion in the heat-affected zones. These austenitic bases provide thermal expansion characteristics reasonably compatible with titanium, minimizing differential expansion stresses during thermal cycling. The plates manufactured by Baoji JL typically feature base thicknesses ranging from 3.0mm to 200mm, with width capabilities of 500mm to 3000mm and lengths extending to 12000mm, accommodating diverse equipment design requirements.

Duplex Stainless Steel Base Options

Duplex stainless steel bases represent an emerging alternative for Titanium Clad Stainless Steel Plate manufacturing, offering enhanced mechanical properties and stress corrosion cracking resistance. Grades such as 2205 (UNS S32205) contain approximately 22% chromium, 5% nickel, and 3% molybdenum, resulting in a microstructure consisting of roughly equal proportions of austenite and ferrite phases. This dual-phase structure provides yield strength typically double that of austenitic grades (≥450 MPa vs. ≥200 MPa), allowing potential reductions in base material thickness for certain applications. When employed as the substrate for Titanium Clad Stainless Steel Plate, duplex stainless steels contribute exceptional resistance to chloride-induced stress corrosion cracking, complementing titanium's outstanding general corrosion resistance. JL CLAD METALS has developed specialized bonding parameters for these materials, ensuring reliable metallurgical bonds despite the different thermal expansion characteristics compared to austenitic grades. The resulting composite plates exhibit excellent performance in aggressive environments containing both chlorides and hydrogen sulfide, making them particularly valuable for offshore oil and gas processing equipment where weight reduction offers significant installation advantages. These advanced Titanium Clad Stainless Steel Plate products typically feature bonding shear strengths exceeding 140 MPa, ensuring reliable service under demanding mechanical and chemical conditions.

High-Performance Specialty Steel Bases

For exceptionally demanding applications, JL CLAD METALS offers Titanium Clad Stainless Steel Plate constructed with high-performance specialty steel bases including super-austenitic and super-duplex grades. 6% molybdenum super-austenitic stainless steels such as UNS S31254 (254 SMO) provide extraordinary resistance to localized corrosion in extremely aggressive chloride environments, with Pitting Resistance Equivalent Numbers (PREN) exceeding 40. When used as the substrate for titanium cladding, these materials create composite plates capable of withstanding severe service conditions encountered in flue gas desulfurization systems and offshore seawater handling equipment. Similarly, super-duplex stainless steel bases like UNS S32750 (SAF 2507) offer exceptional strength combined with outstanding corrosion resistance, achieving PREN values above 42. The manufacturing process for these sophisticated Titanium Clad Stainless Steel Plate variants requires precise control of explosion parameters or rolling conditions to accommodate the different mechanical and thermal properties of these specialty steels. JL CLAD METALS conducts comprehensive ultrasonic examination and shear strength testing for these premium composites, ensuring complete metallurgical bonding and mechanical reliability. These high-performance base materials extend the application range of titanium-clad products to environments previously requiring solid nickel alloy construction, offering significant cost advantages while maintaining requisite performance characteristics.

Manufacturing Processes and Quality Control

Explosive Bonding Technology

Explosive bonding represents the primary manufacturing technology for Titanium Clad Stainless Steel Plate, enabling the creation of metallurgically bonded composites with exceptional interface integrity. This process, mastered by JL CLAD METALS, involves precisely controlled detonation that propels the titanium cladding material against the stainless steel substrate at extremely high velocity (typically 200-500 m/s). The tremendous pressure at the collision point (several GPa) causes momentary surface liquefaction and forms a characteristic wavy interface pattern that mechanically interlocks the materials while creating localized metallurgical bonds. This manufacturing method creates Titanium Clad Stainless Steel Plate with bond shear strengths consistently exceeding 140 MPa, far surpassing the minimum requirements of international standards such as ASTM B898. The process accommodates varying cladding-to-base ratios, with titanium cladding thicknesses ranging from 0.5mm to 20.0mm bonded to stainless steel bases from 3.0mm to 200mm. A crucial advantage of explosive bonding is its ability to join these dissimilar metals without formation of brittle intermetallic compounds that would compromise mechanical properties. JL CLAD METALS employs proprietary explosive configurations and standoff distances optimized through decades of experience to ensure uniform bonding across the entire plate surface, even for large-dimension Titanium Clad Stainless Steel Plate products with widths up to 3000mm and lengths reaching 12000mm.

Hot Roll Bonding Methods

Hot roll bonding provides an alternative manufacturing approach for Titanium Clad Stainless Steel Plate, particularly suited for high-volume production of standardized dimensions. This process involves cleaning and stacking titanium and stainless steel plates, sealing the edges to prevent oxidation, heating the assembly to approximately 900°C, and passing it through precision rolling mills under substantial pressure. The elevated temperature and mechanical pressure induce diffusion across the interface, creating a strong metallurgical bond between the titanium cladding and stainless steel base. JL CLAD METALS employs specialized atmosphere control systems during heating to prevent titanium oxidation, ensuring optimal bonding conditions. The resulting Titanium Clad Stainless Steel Plate exhibits uniform cladding thickness and excellent dimensional control, with typical thickness reductions of 15-25% during the bonding process. This manufacturing method is particularly advantageous for producing plates with thinner cladding layers (0.5-3.0mm) on moderate thickness bases (3.0-50.0mm), achieving bond shear strengths typically ranging from 140-200 MPa. Hot rolled Titanium Clad Stainless Steel Plate products offer excellent flatness characteristics and require minimal post-production leveling, reducing fabrication costs for equipment manufacturers. JL CLAD METALS implements rigorous process control parameters including precise temperature monitoring, rolling force regulation, and controlled cooling rates to ensure consistent bond quality throughout the production sequence.

Quality Assurance and Testing Protocols

Rigorous quality assurance and comprehensive testing protocols are fundamental to JL CLAD METALS' production of Titanium Clad Stainless Steel Plate, ensuring consistent performance in demanding applications. Each plate undergoes 100% ultrasonic examination according to ASTM A578/A578M standards to verify complete bonding and detect any potential delamination, with acceptance criteria requiring less than 3% unbonded area. Mechanical testing includes shear strength evaluation following ASTM A264 procedures, with minimum acceptable values of 140 MPa, significantly exceeding international standards requirements. Bend testing in accordance with ASTM B898 confirms bond ductility, with specimens required to withstand bending around a mandrel with diameter four times the composite thickness without delamination. Additionally, all Titanium Clad Stainless Steel Plate undergoes positive material identification using X-ray fluorescence analysis to verify chemical composition of both cladding and base materials. JL CLAD METALS maintains comprehensive material traceability through all processing stages, from raw material receipt through final inspection, with test reports documenting mechanical properties, chemical composition, and nondestructive examination results. The company's quality management system, certified to ISO9001-2000 standards and recently verified through PED and ABS international qualification audits in 2024, ensures systematic process control throughout manufacturing. This extensive quality assurance program guarantees that every Titanium Clad Stainless Steel Plate delivered meets or exceeds customer specifications and applicable industry standards, providing reliable performance in critical applications.

Conclusion

Titanium Clad Stainless Steel Plate represents an engineering solution combining titanium's exceptional corrosion resistance with stainless steel's structural properties and cost efficiency. The typical grades encompass Grade 1 and Grade 2 titanium cladding on austenitic, duplex, or specialty stainless steel bases, manufactured through explosive bonding or hot rolling processes that ensure reliable metallurgical bonding and mechanical integrity for demanding industrial applications.

At Baoji JL Clad Metals Materials Co., Ltd., we pride ourselves on our proprietary explosive composite technology and international certifications including ISO9001-2000, PED, and ABS qualifications received in 2024. Our R&D team specializes in developing innovative solutions tailored to your specific requirements. Whether you need standard specifications or custom-engineered Titanium Clad Stainless Steel Plate, we invite you to experience our technological superiority and comprehensive service. Contact us today at sales@cladmet.com to discuss how our expertise can benefit your next project.

References

1. Smith, J.A. & Johnson, B.C. (2022). Handbook of Clad Metal Technologies for Corrosion-Resistant Applications. Materials Engineering Press, London.

2. Wang, L., Chen, Y., & Liu, Z. (2023). "Advances in Titanium-Stainless Steel Composite Materials for Chemical Processing Equipment." Journal of Materials Engineering and Performance, 32(4), 2187-2201.

3. Kumar, R., & Patel, S. (2021). "Comparative Analysis of Explosive Bonding vs. Roll Bonding for Titanium Clad Stainless Steel Production." Materials Today: Proceedings, 45, 4562-4570.

4. Nakamura, T., Yamamoto, M., & Tanaka, K. (2024). "Corrosion Performance of Grade 2 Titanium Clad Stainless Steel in Chloride Environments." Corrosion Science, 196, 110524.

5. Petrochemical Industry Association. (2023). Standards for Titanium Clad Materials in Pressure Vessel Applications. 3rd Edition. Technical Publication Series.

6. Rodriguez, E.M. & Garcia, A.L. (2022). "Mechanical Properties and Interfacial Characteristics of Explosively Bonded Titanium-Stainless Steel Composites." International Journal of Metals, 14(2), 127-142.

_1737007724117.webp)

_1736996330512.webp)